minimum bend radius formula for sheet metal A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius . $59.99

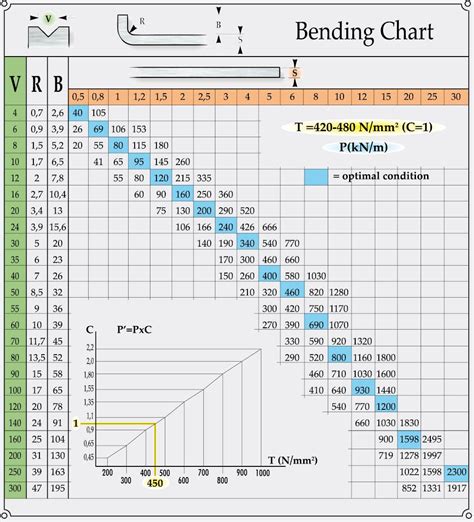

0 · sheet metal bending chart

1 · sheet metal bending angle chart

2 · sheet metal bend radius standard

3 · sheet metal bend radius calculator

4 · sheet metal bend calculation formula

5 · calculate bend radius for steel

6 · blank size calculator sheet metal

7 · bend radius sheet metal chart

Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere!

sheet metal bending chart

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [ (0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend . In steel between 0.5 and 0.8 in. thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s . A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius .We’ve broken down our minimum bend radii into two values: minimum hole distance and minimum flange distance. Minimum hole distance specifies how far a hole must be placed from the bend radii to ensure it will not warp.

Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for . The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R.Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary operations and is far more costly.

We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, .In this Tech Tip, we will explore the various bend calculation options available for sheet metal, namely K Factor, bend allowance, and bend deduction, and guide you on when to use each.Bend Radius Bend Relief Forming Near Holes Form height to thickness ratio . To save the cost of punching or drilling in a secondary operation the following formulas can be . > 1" diameter then the minimum distance "D" = 2.5T + R (see fig. "C") Form height to thickness ratio – To determine the minimum form height for sheet metal use the .Bend Radii & Minimum Bend Sizes. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values that are both manufacturable and meet your needs. If you need help choosing a value, contact us at [email protected] or 1-866-849-3911 and we can help .

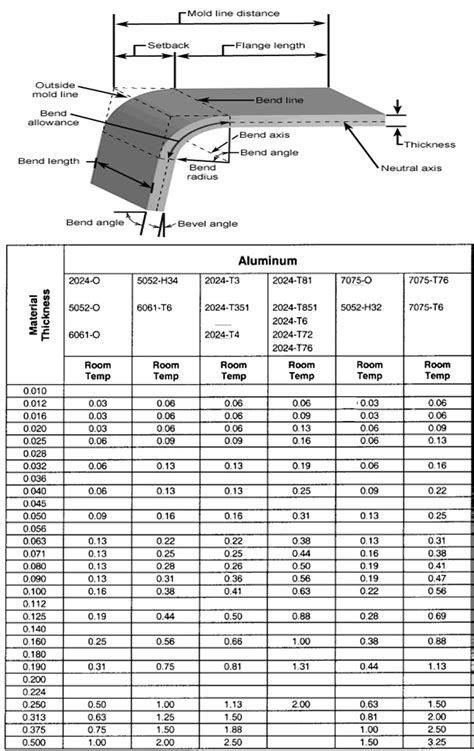

For a sheet metal stock with inch thickness, determine the minimum tool radius for both the steel and aluminum alloys that will not tear the material. Assume the sheet of material is in pure bending (i.e., no additional tension is . Input Material Thickness and Inner Radius: • Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate bending calculations. . In sheet metal bending calculations, the impact of different material types on the bending . The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness.

Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. . This chart shows a minimum bend radius of 0 to 1 times the material thickness for 0.125-in.-thick 5052-H32. . To find the correct percentage and predict the inside radius, we .The formula for the minimum bending radius is: ri = c x s. The minimum bending radius is obtained by multiplying the thickness of the material (s) by the coefficient (c) of the material, which varies according to the specific material and the conditions under which the sheet is bent.

Study with Quizlet and memorize flashcards containing terms like Bend Radius, Measuring the size of the bend, the diameter is and more. . Aircraft Sheet Metal (Bending) Flashcards; Learn; Test; Match; Q-Chat; Get a hint. Bend Radius. . Minimum Bend Radius. 2 - 4T. Factors that determine minimum bend radius. Thickness. Composition. Temper.

Here you can specify many of the sheet metal specific properties including bend radius, K-factor, and bend relief dimensions. These can be fixed values or formulas based on the material thickness. (Note: you can find all of this information for your chosen material and thickness in our bending calculator as well.)

Bending Radius Bending Radius refers to the minimum radius that can be applied to a sheet metal component where its flange originates from. Bending radii are usually dictated by available tooling, and for quick and effective design work it is recommended to speak with manufacturers so that design can be done around their standard operating procedures as well as available tooling.

As a general recommendation, ±0.005 in. runs right at the limit of precision flat sheet metal in a job shop environment. For bent sheet metal, variation in the raw material thickness increases the recommended precision to ±0.010 in. per bend. Layout Method for Sheet Metal “Sheet metal stretches when it bends” is an oversimplification.You can derive the Bend Allowance (BA) by using the K , Bend Radius (R), Bend Angle (A) and Material Thickness using the formula below. BA=Pi*(R+K*T)*A/180. In this formula: K represents the K-factor. BA is the bend allowance. A is the bend angle. R . Use This Flange Formula for Sheet Metal Forming (Updated for 2024) Forming, Precision Sheet Metal Fabrication, Sheet Metal Capabilities, Sheet Metal Design / 6 minutes of reading / October 18, 2022 . . 4x Material Thickness + . An overview of bend radius for sheet metal, including types, materials, tools, and important design considerations is provided in this article. +1(213) 398 9420 +86 13922902420; [email protected]; . A commonly used formula for calculating the minimum inside bend radius is:

Determining the bending radius of sheet metal is crucial to ensure successful and accurate bending operations without causing damage to the material. The bending radius is the minimum radius at which a sheet metal .

sheet metal bending angle chart

It shall be equal to three times of sheet thickness plus bend radius. Minimum Sheet Metal Flange Bend Length = 3 x Sheet Thickness + Bend Radius. Sheet metal Hole Diameter Guidelines. Minimum Hole Diameter in sheet metal. . Hi, seem to be a lot of knowledgeable people here re: sheet metal bending. Can somebody please give me a formula that will give a minimum inside bend radius for a given thickness of sheet metal and a given K factor? Sorry if I am covering "done" material but I have searched google and nobody seem to have asked this question. thanks Steve

How much metal is used in a 90 degree bend in 0.064 inch 2024-T aluminum alloy sheet using a 3/16 inch bend radius. Bend allowance for a 90 degree bend may be found by using this formula. Bend allowance= [(0.01743 R)+(0.0078 T)]*degree of bend 0.342 inchThe minimum bend radius of sheet metal depends on various factors such as the thickness and type of metal, the bending process used, and the desired bend angle. Typically, a good rule of thumb for determining the minimum bend radius is to use a multiple of the sheet thickness. For example, the minimum bend radius for a sheet metal with a thickness of 1mm would be .Minimum Bend Radius. Minimum bend radius is a critical parameter which depends on both material and process used to produce the bend. More the ductility of the material, smaller the bend radius which can be achieved. The guideline suggests that the inside bend radius should be at least equal to the sheet thickness. Preferably, the inside bend .What is the minimum bend radius for a 1.0-mm-thick sheet metal with a tensile reduction of area of 30%? . Question: I Q 1. What is the minimum bend radius for a 1.0-mm-thick sheet metal with a tensile reduction of area of 30%? Does the bend angle affect your answer? Explain. kindly show formulas and tables if needed. Show transcribed image .

the direction of lay of a piece of sheet metal. grain determined. determined by the manufacturing process . Bend Radius. distance from center of the bend circle to inside of bend material. Bend Radius info. all materials have a minimum bend radius found in table 4-6, page 4-4 in the A.C. 43.13-1B also found in figure 4 . Bend Allowance . 3)Reduction formula (empirical value of gooseneck punch ) 0.5MM sheet: Minimum U bending: A =7.67, B= 0.5, minimum L bending=3.0. Increasing value: whenever A increases by 1mm, B increases 1.87 accordingly.What is the minimum bend radius of a sheet metal? Don't know? Terms in this set (51) . What should not be used when doing a layout on sheet metal aluminum? A scribe. What is used as an aid when doing layout work with pencil? . What is the Empirical formula used to find? Bend allowance. About us. About Quizlet; How Quizlet works; Careers;

We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, the minimum bend radius should be 1 mm. Sheet Metal Bending Radius refers to the minimum radius that can be applied to a sheet metal component where its flange originates from. . Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. . Exploring Press Brake Bend Allowance: Formula,Calculator .

junction box stud bracket

CNC Router For Sale, Used Industrial CNC Router Inventory Updated Daily, Top Brands Like Laguna, Shopbot, Elephant & More

minimum bend radius formula for sheet metal|sheet metal bend radius calculator