peek cnc machining manufacturer CNC Machining for PEEK Parts. PEEK parts are high-temperature engineering thermoplastics that maintain excellent flexural, impact, and tensile characteristics. Get A Quote. Tuf-Tite 9-Hole Distribution Box. Comes complete with a lid. Lid is 16' x 16'; Box is 14-1/2' tall; There is a 2' drop between inlet and outlets. Includes 6 Orange Seals & 6 Yellow Rings.

0 · peek vs acetal

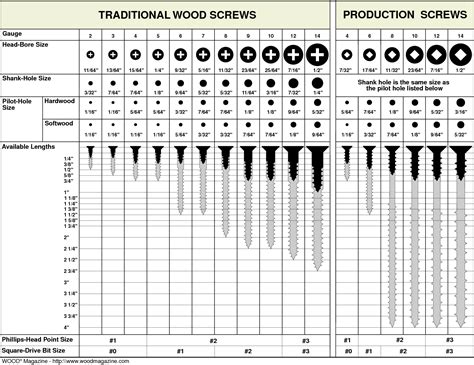

1 · peek screw size chart

2 · peek material machinability

3 · machining peek plastic material

4 · machining peek plastic

5 · how to anneal peek

6 · delrin vs peek

7 · can you machine peek

Tuf-Tite 4-Hole Distribution Box. Comes complete with a lid. Lid is 11' x 11' -- Box is 15-1/2' tall -- There is a 2' drop between inlet and outlets for proper flow to the field lines. Used with multiple schedules of 4' Pipe sch40 pvc, sch 20 pvc, sdr 26 green pvc pipe. Includes 3 Orange Seals & 3 Yellow Rings. The rings are for different such .

peek vs acetal

CNC Machining for PEEK Parts. PEEK parts are high-temperature engineering thermoplastics that maintain excellent flexural, impact, and tensile characteristics. Get A Quote. ProleanTech stands at the forefront of PEEK CNC Machining and is recognized as a leading Online PEEK CNC Machining service provider. Our expertise extends to delivering Expert PEEK Machining Solutions, ensuring .

CNC machining materials. CNC machining in PEEK. High-performance thermoplastic, very high strength, thermal and chemical resistant. PEEK is a high-performance engineering thermoplastic with excellent mechanical properties .

single gang box electrical

PEEK has excellent applications in electronics, medical, communications, machinery manufacturing and aerospace. PEEK bar (polyetheretherketone bar), the material density is about 1.32, the high temperature is 300°, the material . PEEK For CNC Machining. PEEK is a semi-crystalline thermoplastic that can operate continuously at temperatures up to 250°C, while also having high chemical resistance. . some of which are better processed . PEEK (polyether ether ketone) is an advanced engineering plastic with several beneficial properties. These include high temperature elasticity, abrasion resistance, biocompatibility, ultra-high vacuum resistance, excellent chemical resistance, and suitability for CNC machining.PEEK is a semi-crystalline thermoplastic that can operate continuously at . We did lots of Vespel 21 and PEEK. PEEK is not as strong as Vespel, but we had no trouble machining it. We used HS and Carbide, depending on the machinist and the job. It by nature is a tough plastic, but it handled well We used it to make precision seals , like 7.5000 OD x7.0000 ID x.375. tolerance was.0005 What is touchy is the expansion rate.

RpProto offers custom PEEK CNC machining services, including milling and turning. It is capable of manufacturing PEEK parts efficiently in both prototyping and large-volume runs. Precision machining PEEK plastic allows for the creation of complex, high-tolerance parts with excellent mechanical properties and accuracy. CNC machining has numerous benefits in the processing of PEEK plastics, and as a result, it is an option that every manufacturer seeking efficiency and accuracy should go for. First, the company’s widest depth in CNC machines helps achieve accuracy and repeatability, which is fundamental when forming complex shapes used in critical design .

Our PEEK CNC machining services offer precision manufacturing of high-performance components from PEEK (Polyether Ether Ketone) materials. Our team of experienced machinists utilizes advanced CNC machines to produce complex geometries with tight tolerances, ensuring the highest quality and accuracy in every part we manufacture. Hey all! I don't post often but I use your information often so thanks to all. Now onto my question. I work on carbon-fiber PEEK material on a regular basis but have not figured out a consistent part-off tool/method to use. Currently we use a combination of HSS Thin-Bit inserts, 2mm and 3mm wide.

Choose us as your PEEK CNC machining services manufacturer, and benefit from our expertise, advanced capabilities, commitment to quality, customized solutions, timely delivery, exceptional customer service, competitive pricing, and strict confidentiality. Contact us today to discuss your PEEK machining needs and experience the difference . Looking for some advice on how to stop PEEK warping when i machine it. I have a 200mm x 65mm x 20mm block of peek of which i need to machine down to 16mm on a VMC but when i take the front and back skin of the material off with a face mill it warps,. Does anybody know how i can prevent this? Thanks in advance. BigJim Tough plastics like PEEK are excellent alternatives for metals during parts fabrication, especially when you need to reduce the weight of said part. PEEK thermoplastic possesses unique properties that make it a good choice for manufacturing parts for different industries. This article will provide detailed info on PEEK plastic machining, exploring its . The variety, quality, and efficiency of machine tools directly impact the level of production technology for other mechanical products. The modernization level and scale of the machine tool are of extreme importance to CNC machining manufacturers. China CNC machining service stands out with mature and cost-effective CNC equipment. 1.

CNC machining outsourcing is a manufacturing strategy that involves contracting with another company for CNC machining services. Whether for prototyping or production, product designers who outsource their machined parts gain access to advanced technology, leverage custom machining solutions, and avoid expensive investments in equipment and . I like machining PEEK you just need to know a few rules. Climb mill, leave .015 thou. or so to finish. Avoid breaking through on an edge. Rough machine both edges and break through in the center ( with a .015 or so left on the floor for cleanup with sharp finish tool. Sharp carbide uncoated.

PEEK CNC machining. In navigating the complexities of PEEK machining, the integration of these specialized techniques underscores the importance of precision engineering in achieving excellence.The meticulous .

Custom PEEK Turning Services – OEM China CNC Turning PEEK Parts Manufacturer & Company. Pinjin is a professional peek machining company in PEEK turning service, our knowledgeable team and advanced turning .

PEEK CNC machining is more than just a manufacturing process - it's an avenue for innovation, progress, and invention. It's not just about creating a part or fulfilling an order. It's about pushing the boundaries of what's possible, questioning the status quo, and driving towards a future where the full potential of this incredible material is .Manufacturing. Machining. Auto Quote Capabilities Materials . CNC machining PEEK Materials PEEK is a semicrystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures. .3Q MACHINING is known for producing quality screw machine products from PEEK plastic. We can machine intricate parts on our CNC Swiss machines and CNC turning centers. Polyether ether ketone (PEEK) is a popular high strength plastic resin, ideal for parts that require strength and stiffness. It has an extremely high resistance to heat, moisture,.ShenZhen Ruixing Precison MFG is End-to-End Management CNC machining parts manufacturer with 18 years of experience. We provide custom machining service, stable product quality, in-time delivery and satisfied customer service. . PEEK. FR4. PMMA (Acrylic) Polyethylene (PE) Polycarbonate (PC) Polypropylene (PP) Choose items. Material. textarea .

Tool selection: High-temperature and high-wear resistant tools should be selected for machining PEEK to reduce maintenance frequency and improve machining efficiency. Environmental considerations: Although PEEK has excellent chemical stability, good ventilation should be ensured during processing to prevent any possible accumulation of toxic gases.SINCO-CNC, a leading manufacturer of precision machined components, offers a range of PEEK gear products designed for high-performance applications. Made from Virgin PEEK, LF30-PEEK, GF30-PEEK, and CF30-PEEK, these gears are highly durable, self-lubricating, flame-resistant, and capable of withstanding extreme temperatures from -160°C to +260°C. I have a project to make a few prototype parts that are made of 30% Glass Filled PEEK. I'll be using a Haas CNC and would like to machine dry with a vacuum to keep the machine clean but I'm not sure if this is necessary. I could .

With PEEK you can treat it like a free machining metal in most cases. Clearing chips is the only difficulty, I try to drill leaving just a few thousands of an inch to clean up with a boring bar. You leave too much in the hole and the chips can pack up and deflect the boring bar.Machine Type: CNC (Computer Numerical Control) Milling Machine Max Workpiece Size: 1000mm x 800mm x 500mm Tool Magazine Capacity: 20 Tools Spindle Speed: 10,000 RPM

Aixi Hardware is a Precision CNC Machining manufacturer. Our services include CNC Milling, Turning, 5-axis Machining, and Anodized Aluminum. Skip to content [email protected] +86 13342948130 . CNC Machining PEEK; CNC Machining Titanium; Additional Services. Extrusion Services; Stamping Molding; Pressure Die Casting; Metal Forging; Thread .

simpson sheet metal in santa rosa

Bend Tooling is the premier tooling supplier in the US and worldwide, offering durable mandrels, dies, and other tube-bending machine parts.

peek cnc machining manufacturer|how to anneal peek