cnc machine types ppt There are many different types of CNC Machines used in industry, Such as: Mills and Machining Centers. Lathes and Turning Centers. Drilling Machines. EDM Sinker and wire cut Machines. .

What is an electrical junction box used for? An electrical junction box is used for several purposes, including: Containing and protecting electrical connections, such as wire splices and wire terminations. Preventing contact with live wires, which reduces the risk of electrical shocks and fires.

0 · cnc machine tools ppt

1 · cnc machine ppt template

2 · cnc machine ppt download

3 · cnc machine maintenance ppt

4 · cnc lathe machine working ppt

5 · cnc lathe machine ppt download

6 · cnc drilling machine pdf

7 · basics of cnc machine ppt

Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. See more

cnc machine tools ppt

baby box distribution calgary

cnc machine ppt template

The document discusses different types of CNC machines. It describes 8 common types: CNC lathe, milling machine, router, laser cutter, plasma cutter, 3D printer, pick and place machine, and 5-axis machine.CNC machines are computer-controlled machines that automate manufacturing .The key elements of a CNC machine are described as the input device, machine .

CNC machines are computer-controlled machines that automate manufacturing processes and increase productivity. There are several main types of CNC machines, including milling machines, plasma-cutting machines, lathe . The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation .There are many different types of CNC Machines used in industry, Such as: Mills and Machining Centers. Lathes and Turning Centers. Drilling Machines. EDM Sinker and wire cut Machines. .

Types of CNC Machines. Some of the most common processes operated by CNC include ultrasonic welding, hole drilling and laser cutting. The most used machines in CNC systems include the following: CNC milling .Learn about CNC machines, their applications, types, components, programming, machining, and maintenance. Download PPT presentations on CNC topics from Sigma Technik, a CNC .

backyard grill stainless steel smoker box

Types of CNC Machines. Some of the most common processes operated by CNC include ultrasonic welding, hole drilling and laser cutting. The most used machines in CNC systems include the following: CNC milling .Download ppt "Introduction to CNC Machining". Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves .3 Types of CNC Milling Machines Types of milling machines: vertical and horizontal machining centers (VMC and HMC) ATC types: carousel-type and swing- arm-type 3. 1.2 Introduction Milling is a cutting operation with a geometrically specified cutting edge in which the tool makes the rotating main movement, and the feed as well as the infeed movement are generally made by the work part. .

6. • Automatic work part Positioned: Many horizontal and vertical machining centers have the capability to orient the work part relative to the spindle. This is accomplished by means of a rotary table on which work part is . 6. • Base of both milling machines supports the entire machine. • Column also a structural member which houses the knee, spindle, bearing, gear box, clutches, shaft, pumps, power transmission mechanism for motor to . Cncpresentation CNC lathe machine - Download as a PDF or view online for free . Different types of CNC machines such as mills, lathes, and EDM machines are covered. The presentation also discusses CNC programming basics including codes, tool paths, and an example programming for a cylindrical part. Read less. Read more.

3. Why is CNC Machine Centre Used? Manufacture of prismatic components like gear boxes, bulkheads, frames, covers etc requires different types of operations like milling, boring, drilling, tapping and other many related machining operations. Before the introduction of CNC machines centers this operations where done on different machines which leads to .

Introduction to G-code • The most common codes used when programming CNC machine tools are G codes, other codes such as F, S, D, T, etc which are used for machine functions such as feed, speed, cutter diameter offset, tool number, etc • G codes are preparatory functions which instruct the machine tool to get prepared for the operation to .

Types of CNC Machines Some of the most common processes operated by CNC include ultrasonic welding, hole drilling and laser cutting. The most used machines in CNC systems include the following: CNC Milling Machines CNC milling machines are capable of running in programs that consist of indications based on numbers and letters, which guide the .

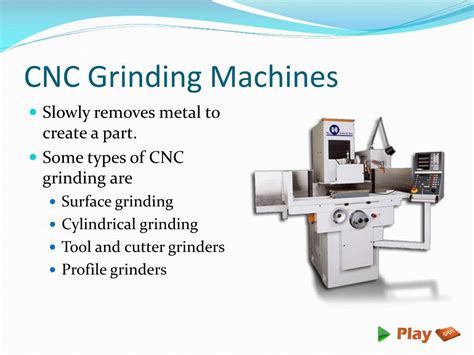

5. INTRODUCTION 5 • A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the work piece via shear deformation. • Grinding is used to finish work pieces that must .

There are different types of CNC machines for various operations like lathes, mills, routers, lasers, and plasma cutting. CNC machines work by using G and M codes input through programming software to control tool movements and machine functions. The main advantages of CNC machines are high precision, repeatability, flexibility, and increased .Introduction CNC milling machines perform same functions as manual, and creates arcs, contours and 3D surfaces FIGURE CNC milling machines can produce complex part surfaces that would be virtually impossible to produce with manual milling machines. Photo courtesy of Haas Automation, Inc.•What is a CNC Machine? •CNC : Computer Numerical Control •Conventionally, an operator decides and adjusts various machines parameters like feed , depth of cut etc depending on type of job , and controls the slide movements by hand. In a CNC Machine functions and slide movements are controlled by motors using computer programs. CNC Machining Centers are classified THREE types 1.A vertical machining centre (VMC) :-It has its spindle on a vertical axis relative to the work table vertical machining centre is typically used for flat work that requires tool access from top. Milling Centre is a type of vertical machining centre Prepared by: Prof. Rahul Thaker (ACET)

• Type of part programming 1. Manual part programming 2. Computer aided part programming • CNC programmers write instructions for CNC machines, where a computer is connected to the mill, along with electrical drives and sensors for a complete system. This computer controls the movement of the machine axis.

UNIT 5 – Numerical Control (NC) machine tools – CNC types, constructional details, special features, machining centre, part programming fundamentals CNC – manual part programming–micromachining – wafer machining. 2. 3. The first NC machines were built in the 1940s and 1950s by Prof. John T Parson. CNC machine came into existence after evolution of computer around 1980. Modern CNC Machine are improving further as the technology is . Also See: Hyper-Threading Technology ppt. Here we are giving you CNC Machines Seminar and PPT with PDF report. All you need to do is just click on the download link and get it. CNC Machines PPT and Seminar Free Download. CNC Machines pdf Report Free Download. It was all about CNC Machines Seminar and PPT with pdf report. If you liked it then .

3. CNC MACHINING The use of computers to control machine tools Tools include lathes, mills, drills and grinders. Machine tools function through numerical control A computer program is customized for an object and . The document then describes the hardware components and configuration of CNC machines, including their control units, drives, slideways, spindles, and programming. It also covers different CNC machine types like machining centers and turning centers, as well as their programming and control systems. Read less

CNC Machines - Download as a PDF or view online for free. Submit Search. CNC Machines • Download as PPT, PDF . Axis designation for each type of machine tool is suggested in the EIA (Electronic Industries Association) RS 274-B standard. This conforms to ISO Recommendations R831. The nomenclature of the three main axes (X, Y AND Z) is based .

3. Introduction to CNC 3 • Numerical control (NC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually. • Most NC today is computer numerical control (CNC), in which computers play an integral part of the control. • In modern CNC systems, end-to-end .

CNC TURNING. (FANUC SYSTEM). INTRODUCTION FUNDAMENTAL PRINCIPLES INSTRUCTION. 1. INTRODUCTION. Ways of Turning Parts of CNC Machine Working Methods of CNC. Ways of Turning. Conventional or Traditional Numerical Control (NC) Computer Numerical Control (CNC).

7. Milling machine As the workpiece moves against the cutting edges of milling cutter, metal is removed in form chips Machined surface is formed in one or more passes of the work. The work to be machined is held in a vice, a rotary table, a three jaw chuck, an index head, in a special fixture or bolted to machine table. In many applications, due to its higher . Cnc tooling for cnc machine(130670119596) - Download as a PDF or view online for free. Submit Search. . The two most common axis types are: 1.linear(driven along a straight path) 2.Rotary(driven along a circular path) 6. Identification of work piece material 7. 12. CNC Machine Operating Modes AUTO Mode: In automatic mode, individual NC traversing programs are processed. The axes cannot be traversed by means of the direction keys. In this mode machine works in part programs .Part program is program of particular job. part program contains various codes like that the numeric value of axis position ,tool command, .

It is one of the most common types of CNC machine, that have built-in tools for drilling and cutting. The materials are located inside a milling CNC machine, after which the computer will lead the tools to drill or cut them.. Most of the CNC milling machines are available in 3 to 6-axis configurations. This machine is used to produce gears like spur gear and is also . 8. Automatic Tool Changer Mechanism After receiving the tool change command, the tool to be changed will assume a fixed position known as the "tool change position". The ATC arm comes to this position and picks up the tool. The arm swivels between machine turret and magazine. It will have one gripper on each of the two sides. Each gripper can rotate 90°, to . Lathe machine ppt - Download as a PDF or view online for free . bed, carriage, cross-slide, apron, tailstock, tool post, and quick-change gearbox. It also covers lathe safety, types of lathes, cutting speeds, lathe accessories such as centers, chucks, faceplates, and work holding methods. . Centre Lathe • lathes may be operated directly .

Metal beds are an equally popular choice and work perfectly well for sleepers around the world. Durable and sturdy, metal bed frames are a reliable option in the bedroom and are often very reasonable in price.

cnc machine types ppt|cnc drilling machine pdf