cnc machine collision Once you have a collision avoidance system on your CNC machine, there are five models that must be addressed to create an efficient manufacturing process. Ultra-precision machining (UPM), which is capable of fabricating micro-components with less than 0.2 µm forming accuracy and 10 nm surface accuracy, is becoming increasingly important due to its indispensable and widespread application in various high-tech fields such as optics, electrics, and semiconductor.

0 · okuma cnc machine collision avoidance

1 · okuma cnc machine

2 · cnc machine collision avoidance

3 · cnc collision avoidance tool

4 · cnc collision avoidance program

Check out our metal u shaped brackets selection for the very best in unique or custom, handmade pieces from our shelving brackets shops.

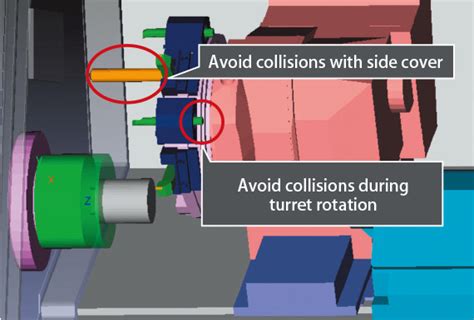

CNC machine collisions can cause costly damage and slow down production. In this video Okuma explains the 5 keys to collision avoidance. The CNC automatically alerts a potential collision by highlighting the relevant structure of the machine onscreen. Headstock, spindle, rotary . Once you have a collision avoidance system on your CNC machine, there are five models that must be addressed to create an efficient manufacturing process.ModuleWorks Collision Avoidance protects CNC machine tools against operating, parametrization, and programming errors during the production process. Collision Avoidance .

Collision detection and avoidance are the main problems in machining of sculptured surfaces. Collision problems in five-axis machining can be classified into two types: local and .

Real-time collision detection running on the CNC controller finds and prevents collisions before they happen. This two part article explains why collision avoidance on the CNC machine is indispensable and how you can .Maximize machine utilization rates via shorter setup, trial cut, and less machine downtime; Enhance productivity with shorter trial cuts that allow machinists to concentrate on machining; .In CNC production, one of the top priorities is collision avoidance. Collisions can result from operational errors and cause significant damage on the workpiece, spindles, and sometimes . Collision Avoidance System (CAS) is a real time software application that works with a highly accurate 3D CNC machine model and the power of Okuma’s THINC® OSP CNC .

CNC machine collisions can cause costly damage and slow down production. In this video Okuma explains the 5 keys to collision avoidance. The CNC automatically alerts a potential collision by highlighting the relevant structure of the machine onscreen. Headstock, spindle, rotary table trunnion, tombstone fixturing, or a simple clamp’s position can be monitored in this real-time collision avoidance program. Once you have a collision avoidance system on your CNC machine, there are five models that must be addressed to create an efficient manufacturing process.ModuleWorks Collision Avoidance protects CNC machine tools against operating, parametrization, and programming errors during the production process. Collision Avoidance is available in two product variants, Core and System (CAS), to fulfil the market requirements for both standardization and customization.

before cnc machining

Collision detection and avoidance are the main problems in machining of sculptured surfaces. Collision problems in five-axis machining can be classified into two types: local and global collision (Figs. 1, 2). Local collision includes local gouging and rear gouging (Fig. 1 (a), (b)). Real-time collision detection running on the CNC controller finds and prevents collisions before they happen. This two part article explains why collision avoidance on the CNC machine is indispensable and how you can ensure real-time performance, even on CNC controllers with less powerful processors.Maximize machine utilization rates via shorter setup, trial cut, and less machine downtime; Enhance productivity with shorter trial cuts that allow machinists to concentrate on machining; Protect the operator in manual jogging mode; Run at full speed unless there’s a detected collision

In CNC production, one of the top priorities is collision avoidance. Collisions can result from operational errors and cause significant damage on the workpiece, spindles, and sometimes even the whole CNC machine. Collision Avoidance System (CAS) is a real time software application that works with a highly accurate 3D CNC machine model and the power of Okuma’s THINC® OSP CNC control. The ModuleWorks Collision Avoidance System (CAS) is real-time collision avoidance software especially designed for fast and seamless integration into the latest CNC controllers. It is connected to the CNC’s look-ahead buffer to .

CNC machine collisions can cause costly damage and slow down production. In this video Okuma explains the 5 keys to collision avoidance.

The CNC automatically alerts a potential collision by highlighting the relevant structure of the machine onscreen. Headstock, spindle, rotary table trunnion, tombstone fixturing, or a simple clamp’s position can be monitored in this real-time collision avoidance program. Once you have a collision avoidance system on your CNC machine, there are five models that must be addressed to create an efficient manufacturing process.ModuleWorks Collision Avoidance protects CNC machine tools against operating, parametrization, and programming errors during the production process. Collision Avoidance is available in two product variants, Core and System (CAS), to fulfil the market requirements for both standardization and customization. Collision detection and avoidance are the main problems in machining of sculptured surfaces. Collision problems in five-axis machining can be classified into two types: local and global collision (Figs. 1, 2). Local collision includes local gouging and rear gouging (Fig. 1 (a), (b)).

Real-time collision detection running on the CNC controller finds and prevents collisions before they happen. This two part article explains why collision avoidance on the CNC machine is indispensable and how you can ensure real-time performance, even on CNC controllers with less powerful processors.Maximize machine utilization rates via shorter setup, trial cut, and less machine downtime; Enhance productivity with shorter trial cuts that allow machinists to concentrate on machining; Protect the operator in manual jogging mode; Run at full speed unless there’s a detected collisionIn CNC production, one of the top priorities is collision avoidance. Collisions can result from operational errors and cause significant damage on the workpiece, spindles, and sometimes even the whole CNC machine.

okuma cnc machine collision avoidance

okuma cnc machine

Collision Avoidance System (CAS) is a real time software application that works with a highly accurate 3D CNC machine model and the power of Okuma’s THINC® OSP CNC control.

beaver cnc machines

Brackets. Metal brackets come in a wide range of types and shapes, suitable for uses of all kinds of jobs in and around the home, we're confident you'll find the bracket you need. A metal bracket is most commonly used to connect 2 pieces of material, which may be the same or different from each other and most commonly used for woodworking projects.

cnc machine collision|okuma cnc machine