wire welding sheet metal Now that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See more Chapman Electric Supply carries underground enclosures, access boxes and covers in a wide range of sizes to meet your needs. They are ideal for telecommunications, underground utility. electrical, or turf applications.

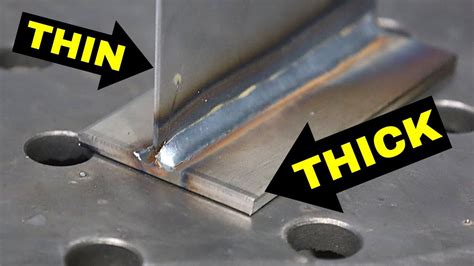

0 · welding thin to thick metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · welded sheet metal manufacturing

4 · sheet metal welding methods

5 · best welding for thin metal

6 · best welder for sheet metal

7 · 18 gauge weldable sheet metal

Originally founded in 1979 by Theodore Pitsios as a top side marine repair service, UMS quickly became an industry leader with an emphasis not only in marine repair, but pulp and paper, .

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See more

Now that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See moreWelding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See moreWelding sheet metal with a wire feed welder involves preparation, precision, and proper technique to achieve strong, clean welds. From selecting the right equipment to finishing the weld, each step plays a crucial role in the process. Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several tips so make sure you watch til.

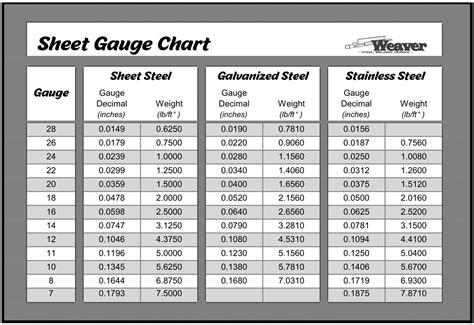

Metal Thickness Gauge Function——The Thickness Gauge can helps you check metal sheet thickness or wire diameter before welding or working. By use this metal thickness template, you can get the thickness of your metal sheet, and that will help you weld better and avoid .

welding thin to thick metal

welding 14 gauge sheet metal

Welding sheet metal with Mig wire requires you to consider the following essential factors. Use a Correct Mig Wire Size for Different Gauge Sheet Metal; If you are welding light gauge sheet metal, a .023- or .024-inch wire is . In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we. The arc melts the electrode and forms the weld to join the connected work piece to another piece of metal. Many metal inert gas (MIG) welding machines are capable of flux-core welding, but unlike the MIG or gas metal arc welding (GMAW) process, an external shielding gas is usually not required to protect the weld from contaminates when welding . For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel .

Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness and refer to the corresponding joint gap, wire diameter, amperage, and voltage setting for your weld. ZeeDix Portable Metal Sheet Thickness Gauge- Stainless Steel Plated Size Inspection Tool Metal Sheets Wire Welding Material Thickness Gauge . Visit the ZeeDix Store. 4.6 4.6 out of 5 stars 2,630 ratings . 2 Pack Wire Metal Sheet Thickness Gauge Stainless Steel Welding Thickness Gauge Plated Size Inspection Tool Standard Wire Welding Gage Dual . The I-CAR finds it appropriate to use 0.023-inch diameter wire when repairing autos, primarily composed of sheet metal. And a 0.030-inch wire like the Forney flux-cored welding wire is suitable for welding materials that are 18 gauge thick or 4.175 millimeters. . We’ve now got the essential part of welding sheet metal with flux core covered .

MIG welding simplifies the feeding of filler metal, making the welder’s job easier. While the specific material may not be critical, the form of the filler metal is important when working with thin sheet metal. 3. Adjust the Torch Angle. Modifying the torch angle during MIG welding significantly helps prevent burn-throughs. A slower wire feed speed is often preferred for welding thin sheet metals, allowing for better control and fusion without overwhelming the metal with excessive heat input. Fine-tuning the wire feed speed to match the selected voltage setting is essential for achieving a harmonious balance that promotes clean and consistent welds.

welder settings for sheet metal

For thinner gauge sheet metal like 18 or 20 gauge we suggest .023 (6mm) wire in your MIG welder. Keep the Stick Out Short-Stickout of your MIG wire is important when welding any type of metal, but especially sheet metal. Holding the tip too far from the surface will cause the wire to have to come out too far to touch the metal. weldingsupply.com is the best price that I have ever found on the Esab Easy-grind wire,in both .023 and .030 sizes and the silicon bronze wire,also.I actually buy all of my wire and most of my supplies from them.Thier shipping cost is quite low also.Here is a link.You will have to scroll down the page quite a ways.I have introduced several boby .

Flux core welding is like the rebel of the welding world, using a hollow wire filled with flux, while solid core shielded gas welding plays by the rules with a solid wire and external shielding gas. . Addressing Challenges and Tips:Flux core welding, especially on delicate 22-gauge sheet metal, isn't a walk in the park. Burn-through, we're . For welding thinner sheet metal, a 0.030″ wire can provide better control over the heat input and minimize the risk of burning through the metal. Moreover, when selecting the wire, consider: Wire material compatibility with your base metal; The .But in reality, some users are welding with the wrong polarity, are using low-quality wire, or don’t clean the base metal properly. Keep in mind that usually FCAW will work with negative or reverse polarity and don’t be cheap! Invest in . Browse suggested weld parameter settings for Stick Welding, TIG Welding, MIG (Solid-Wire) Welding and MIG (Flux-Core) Welding. They show .030 for 22 gauge.I have been using .035 on my panels.but it's a bit of work trying not to burn through..but I have been doing it directing the heat towards the new steel and letting it flow over.

hendricks metal fabrication

This item: Wire/Metal Sheet Thickness Gauge Welding Gage Plated Size Inspection Tool, Better Quality Than Miller 229895 . .99 $ 6. 99. Get it Jul 23 - Aug 5. In Stock. Ships from and sold by LionsWeld. +Most of the light gauge sheet metal work will require the use of .023- or .24- inch while if you have a sheet metal having a gauge of more than 18-gauge then a .030-inch wire would be the most ideal. A ER70S-6 wire would be most ideal for welding mild steel.It is essential to choose the right MIG electrode and wire for perfect sheet metal welding. We suggest you select the wire with the smallest diameter. Since the wire has less diameter, it also takes less heat. Hence, with less space, the wire will burn or melt the least space on the sheet. On top of it, an electrode with a smaller diameter .The basic schematic diagram of laser indirect shock welding of fine wire to metal sheet is shown in Figure 2. The experimental setup mainly consists of a blank holder, confinement layer, ablative layer, driver sheet, metal sheet, wire, back support, and filler piece. When the pulsed laser beam transmits through the transparent confinement layer .

Explore expert sheet metal welding services, offering precision, durability, and custom solutions for all your industrial and commercial needs. . The process involves using electric current to melt a metal wire (a rod or stick), forming an arc between the adjoining workpieces and the electrode. A MIG welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in MIG welding. . Welding Thin Sheet: Stainless Steel: 0.031: 40-70: 120-150: Lap Joint: Aluminum: 0.125: 130-170: 240-290: Butt Weld: Aluminum: 0.062: 90-130: 200-250: Welding Thin Material: You’ll need lower wire speeds . I also have a spool of Inefil, made in Italy. I use .023 since it is mostly automotive sheet metal I’m welding on. Occasionally I’ll do thicker material and really have to turn up the wire speed. Never had a problem. . E70S-2 welding wire is made up of the following chemical elements: Carbon: 0.05–0.07% ; Manganese: 0.90–1.40% .

I was using 035 flux so making it even more difficult i presume, the thinner you are welding the thinner the electrode/wire you want to use is the presumed equation. . I am trying to still get some feedback about the best wire for my machine to use with thinner sheet metal. I heard Hobart Fabshield 21b was good stuff. Many people seem to . The two most common electrode wire diameters for sheet metal welding are 0.6mm (.023-.025 inch) and 0.8mm (.030 inch). A shielding gas is required to protect the weld puddle from atmospheric contamination during GMA (MIG) welding. The most common shielding gas used for collision repair welding of mild and high-strength steels is a mix of 75 .

Welding Sheet Metal. Welding is an essential process of joining metals together. Different techniques are employed to bond sheet metal, including laser, gas, and tig welding. . To braze weld sheet metal, you’ll need a torch (either oxyacetylene or propane), a filler metal (such as a brazing rod or wire), a flux (to help clean and prepare .There seems to be much difference of opinions on which size wire works best on sheet metal (22 g- 18 g) I've always used .030 in my MM210, harris 20 gauge in my 110 machine. I was wondering what others opinions/results were with .023 or .030. . One minute I welding body panels the next 5-8mm (1/4 - 3/8 at a guesse) and 0.8mm (0.031) seems to .

welded sheet metal manufacturing

SNDOAS 30 Inch Under Cabinet Range Hood - US0475BPB . This black finish painted under cabinet range hood features a 500 CFM strong air .

wire welding sheet metal|18 gauge weldable sheet metal