sheet metal rib forming Roll Forming Process: Roll forming is a continuous process that involves passing a flat metal sheet or coil through a series of rollers, each with a specific shape. These rollers progressively bend and shape the metal into the desired profile, . In general, Class I welders are good for welding almost any type of metal. They are generally skilled welders with a high level of experience. Class I welders are also called general or specialty welders. Class II welders are only allowed to .

0 · sheet metal strengthening ribs

1 · sheet metal stiffening rib design

2 · sheet metal stiffening rib

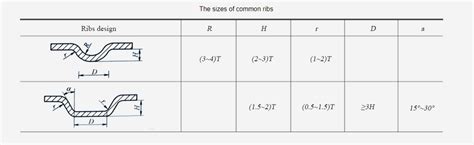

3 · sheet metal rib design guidelines

4 · sheet metal design guideline pdf

5 · how to stiffen sheet metal

6 · hemmed edge sheet metal

7 · classic rib metal roofing panel

What size are electrical box screws? Electrical box screws are typically 6-32 or 8-32 screws. The 6-32 screw is a smaller screw that is used for smaller electrical boxes, while the 8-32 screw is a larger screw that is used for larger electrical boxes.

sheet metal strengthening ribs

Amico 27 in. x 97 in. Domestic Stay Form Metal Rib Forming Sheet. SKU#: 62700530AA. MFG#: 1150001. .99 (EACH)Reduces labor and material costs compared to traditional forming methods for wall joints and “buried” applications. Saves cycle time because the sheet remains in place, only supports and bracing are removed, and form stripping is .

cnc machine suppliers in delhi

The expanded metal sheets are easy to cut, lap, splice, bend and pierce, minimizing related forming costs. When concrete is placed, the ribs and mesh are embedded in the structure, providing a rough surface for subsequent concrete .Roll Forming Process: Roll forming is a continuous process that involves passing a flat metal sheet or coil through a series of rollers, each with a specific shape. These rollers progressively bend and shape the metal into the desired profile, .Stiffening Rib Mode: Forms the sheet metal to create a rib that can be used to stiffen the sheet metal to reduce sheet flex. This is particularly helpful in large unsupported panels. Allows fabricator to reduce sheet metal thickness without compromising the strength and rigidity of the product; Eliminates secondary brake press or welding .

Home » All Products » Forming » Metal rib form. Image Name; OCM Mesh Metal Ribbed Form. This leave-in-place sheet is typically used to form footings, bulkheads, grade beams, pile caps, and blindside walls. Stay Rite Metal Rib form. This leave-in-place sheet is typically used to form footings, bulkheads, grade beams, pile caps, and blindside . Feeds metal sheet into forming stations at set speed: Forming stations: Each station progressively forms the rib shape: Punching unit: Punches holes if required: . Rib sheet metal thickness: Light gauge 0.35 – 0.8mm; Regular gauge 0.8 – 2.0mm; Heavy gauge above 2.0mm; 4. Level of automation:

The Mate Rollerball™ tool creates stiffening ribs and decorative beads in sheet metal parts without a secondary operation. It is available in popular tool st. I'm having trouble putting a rib into a sheet metal part for strength. I would like to put it in along the 90 deg bend in the middle about a 1/4 inch deep. Not sure how to go about doing it. . Use a forming tool to apply the rib. Has to be a sheet metal part There are some samples with Solidworks Gabe Cruz. Answered on 8 May, 2013 01:05 PM .Metal Rib Expanded metal sheet for leave-in-place concrete forming applications Reduces labor and material costs compared to traditional forming methods for wall joints and “buried” applications. Saves cycle time because the sheet remains in place, only supports and bracing are removed, and form stripping is eliminated.

The tool forms the sheet metal by “pinching” the material between two ball bearings in the upper assembly and one ball bearing in the lower assembly. Doing so creates the stiffening rib that can be used to strengthen the sheet metal. The shape of the form is the result of programs created in the punch press programming system. Introduction of special bending tool "Stiffening rib forming" for Bystronic Pressbrakes.Learn more: https://www.bystronic.com/en/products/pressbrakes/press-.Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - . Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of the Using the Rollerball tool is also a better option than using a standard forming tool to make the ribs. Standard forming tools may require tens to hundreds of hits and several minutes to produce strengthening ribs over the length of a sheet. Mate Rollerball reduces machine time to seconds and produces a better looking end result.

Have a look on youtube for hand forming metal and you`ll see a lot of vids from india and such of them turning out excellent work this way. outofthefire Member. Messages 2,871. Oct 19, 2011 . sheet of material clamped over the top but with the outline of the rib cut out and the sheet steel clamped extremely securely between (i.e. the thin .Sheet Metal Forming . Hello, I am new to sheet metal design and am learning about it through reading and videos. I have read that if a sheet is to be formed by use of a die, its formability must be analyzed using a Forming Limit Diagram. The literature said manufacturer’s usually provide this data. . Information about rib design do stiffen . The flat sheet metal part is not strong enough, as it lacks of the structural integrity. In addition, the flat sheet metal part is easy to bend and deform under pressure. Therefore, the flat sheet metal design should be . Roofing sheet roll formers incrementally bend sheet metal into arched ribbed profiles: . Trapezoidal, corrugated, box rib and custom profiles: Secondary operations: Embossing, hole punch, beading, hemming: Metal coatings: . What thickness range can roofing sheet roll forming handle? A: Incoming coil thickness capabilities typically range .

The procedure for forming rib 14 is the same as that used for forming rib l2, and it will be noted that during the forming of rib 14 by V-die 74, the sheet metal on the opposite side of the outer guide lines 24 and 28 moves towards the guide line 26 and the side edge 40 of each slit means 36 of the X-shaped opening moves upwardly in the . Hi, New to sheet metal and I am kinda lost on how to make the reinforcing thingy in the corner of this metal thing. Can anybody point me in the right direction?OCM, Inc. is the Subsidiary of OKABE Co., Ltd., a 100 year old manufacturer & distributor of concrete formwork, form ties, and concrete construction accessories.Our parent company has 8 fully owned manufacturing facilities. All OCM products are quality tested and many have been used in the U.S. concrete construction market for over 35 years.

Download scientific diagram | Rib sizes (measures in millimetres, above) and ribbing process (below) from publication: Sheet metal plate design: A structured approach to product optimization in .Metal Rib Forming – Form in use – after concrete . Leave in place forming – Metal Rib Data Sheet . When a contractor has to form a concrete wall within a few inches of an existing structure, Stay-Form is an excellent product. By utilizing Stay-Form with rebar studs, hook ties, and a modular form system, a one sided form can be .Hi Rib Roll Forming is a specialized manufacturing process that involves shaping flat metal sheets into profiled sheets with raised ribs. This process enhances the strength and rigidity of the sheets, making them ideal for a wide range of applications, including the production of .PROSES PRODUKSI RIB A320 DI SHEET METAL FORMING SHOP Astin Tiara Pratiwi Sunardi1, Erlian Suprianto 2 Program Studi Teknik Industri Fakultas Teknik Universitas Nurtanio Bandung ABSTRAKSI PT. X adalah industri pesawat terbang yang pertama dan satu – satunya di Indonesia dan di wilayah Asia Tenggara.

Metal Rib Expanded metal sheet for leave-in-place concrete forming applications This leave-in-place sheet is typically used to form footings, bulkheads, grade beams, pile caps and blindside walls. The expanded metal sheets are easy to cut, lap, splice, bend and pierce, minimizing related forming costs. When concrete is placed, the ribs and mesh .Mate's family of Roller Solutions™ are the latest example of our superior solutions for sheet metal fabricators. Compared to conventional methods using progressive forming tools, our Roller Solutions help you increase productivity at the press. Roller Solutions can also reduce or eliminate expensive secondary operations One and a half inch spacing center to center 5/16 width of the gusset and then add material thickness to get the outside width of the gusset. The tooling c. Live Stream — How I would create a rib forming tool with Sheet metal.Style: Casual Time: About 15-30 minutes (We all have other things to do :-)Fusion 360 fo.

sheet metal stiffening rib design

sheet metal stiffening rib

cnc machine stl

sheet metal rib design guidelines

Fab shops typically employ several welding methods, including spot welding, tack welding, fuse welding, stitch welding, plug welding, seam/fillet welding, MIG welding, and TIG welding, each with unique applications and characteristics.

sheet metal rib forming|sheet metal rib design guidelines