can i use 3d drawing for cnc machining Find out the 10 steps to prepare a perfect technical drawing for any CNC machining project with a CAD 3D modelling software. The auto, electrical, electronics, medical, and aerospace industries all rely heavily on precisely machined parts to produce products that meet quality and safety .

0 · technical drawing for cnc engineering

1 · how to draw a cnc

2 · drawing for cnc machinery

3 · cnc machining drawings

4 · cnc machining drawing template

5 · cnc drawing requirements

6 · cad for cnc machining

7 · 3d drawing cnc machining

We distribute top-quality industrial tools and machine shop supplies at the best prices. View our collection of CNC machinist supplies and tooling packages. 714.897.1700 Chat Email 844.548.0100

3D drawings or models play an indispensable role in CNC machining for several reasons. Let’s elaborate on some of them in brief. 1. More Detailed and Accurate .

In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques .

You must create a 2D drawing or 3D model and convert it into a program written using G-code and M-code. Next, you then have to import this program file to the CNC machine for execution. To further guarantee success, .

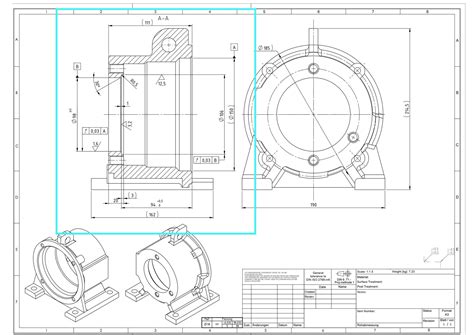

Find out the 10 steps to prepare a perfect technical drawing for any CNC machining project with a CAD 3D modelling software. Current CNC machining systems can read the part’s geometry directly from the 3D CAD file with the on-board computer or from the G-code output of the CAM (Computer-aided manufacturing) software. In this regard, a . Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and .In CNC machining, 3D CAD drawings are used to program the CNC machine to create a physical object. The 3D model is imported into the CNC machine software, and the machine uses the information to guide the cutting tools and .

In 2022, we’re fortunate to be able to import solid 3D models into a CNC machining program — such programs automate the machining steps and parameters needed to produce the desired component.Technical drawings for CNC machining communicate a wealth of information about your part to the manufacturer. Learn how to prepare these drawings best.

Usually, the 3D CAD file is used for programming the CNC machine, and the drawing is used as a reference throughout the machining process. Most CNC service providers can also manufacture parts directly from these CNC turning and milling drawings. 3D drawings or models play an indispensable role in CNC machining for several reasons. Let’s elaborate on some of them in brief. 1. More Detailed and Accurate Representation. 3D models offer a more detailed and accurate depiction of a . In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques such as 3D rendering.

You must create a 2D drawing or 3D model and convert it into a program written using G-code and M-code. Next, you then have to import this program file to the CNC machine for execution. To further guarantee success, preparing the CAD files for CNC machining is advisable. Find out the 10 steps to prepare a perfect technical drawing for any CNC machining project with a CAD 3D modelling software. Current CNC machining systems can read the part’s geometry directly from the 3D CAD file with the on-board computer or from the G-code output of the CAM (Computer-aided manufacturing) software. In this regard, a 2D drawing is not . Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and sent to the CNC machine. The CNC machine reads the PDF and knows how to make the part.

tolworth box junction

In CNC machining, 3D CAD drawings are used to program the CNC machine to create a physical object. The 3D model is imported into the CNC machine software, and the machine uses the information to guide the cutting tools and create the physical object.In 2022, we’re fortunate to be able to import solid 3D models into a CNC machining program — such programs automate the machining steps and parameters needed to produce the desired component.

Technical drawings for CNC machining communicate a wealth of information about your part to the manufacturer. Learn how to prepare these drawings best.

Usually, the 3D CAD file is used for programming the CNC machine, and the drawing is used as a reference throughout the machining process. Most CNC service providers can also manufacture parts directly from these CNC turning and milling drawings.

tolerance in sheet metal fabrication

3D drawings or models play an indispensable role in CNC machining for several reasons. Let’s elaborate on some of them in brief. 1. More Detailed and Accurate Representation. 3D models offer a more detailed and accurate depiction of a . In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques such as 3D rendering. You must create a 2D drawing or 3D model and convert it into a program written using G-code and M-code. Next, you then have to import this program file to the CNC machine for execution. To further guarantee success, preparing the CAD files for CNC machining is advisable. Find out the 10 steps to prepare a perfect technical drawing for any CNC machining project with a CAD 3D modelling software.

Current CNC machining systems can read the part’s geometry directly from the 3D CAD file with the on-board computer or from the G-code output of the CAM (Computer-aided manufacturing) software. In this regard, a 2D drawing is not . Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and sent to the CNC machine. The CNC machine reads the PDF and knows how to make the part.In CNC machining, 3D CAD drawings are used to program the CNC machine to create a physical object. The 3D model is imported into the CNC machine software, and the machine uses the information to guide the cutting tools and create the physical object.In 2022, we’re fortunate to be able to import solid 3D models into a CNC machining program — such programs automate the machining steps and parameters needed to produce the desired component.

technical drawing for cnc engineering

how to draw a cnc

toddler lunch box stainless steel

Get a fast design quote or use eMachineShop’s free CAD to easily design your own camera parts from scratch. Using processes such as CNC machining, injection molding, 3D printing, and waterjet cutting, eMachineShop manufactures custom parts for all types of photography and photonics applications.

can i use 3d drawing for cnc machining|3d drawing cnc machining