programs for cnc machines This CNC programming simulation software is particularly useful for simulating complex 5 axis CNC operations and is a realistic way of cutting tool feeds and speeds to reduce cycle times. The Basics of CNC Simulator . Here are some guidelines for selecting the appropriate junction box for wall sconces: The junction box should comply with local electrical codes and regulations. These codes typically specify .

0 · top 10 cnc programming software

1 · programming software for cnc machines

2 · list of cnc programming software

3 · homemade cnc machine software

4 · cnc programming for dummies

5 · cnc milling machine programming software

6 · cnc lathe programming for beginners

7 · cnc lathe machine software download

Metal fabrication is the process of creating structures and machinery from raw metal materials. Metal fabricators, or the employees who perform this job, are highly important to the industry and need special skills to complete their tasks.

top 10 cnc programming software

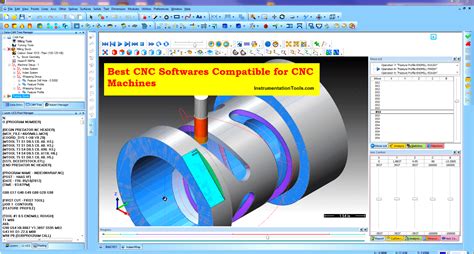

Mastercam. Mastercam is the most popular Computer-aided-manufacturing software used in the manufacturing industry. It provides an extensive set of tools for toolpath generation .

programming software for cnc machines

15 Best Free CNC Software (CAD, CAM, Control, & Firmware) Written by: Leo Watts. February 13, 2024. In this guide, I’ll step you through my hands-on experience with the .Modern CAM software for CNC machining. Autodesk Fusion simplifies and automates the creation of high-quality machine code with professional tools to maximize the use of your CNC machines. Activate your free trial.

Combining CNC software with CNC machines makes the same precision and accuracy of 3D CAD models physically possible. Some CNC software, such as Autodesk Fusion, also includes simulation abilities that test the machining . This CNC programming simulation software is particularly useful for simulating complex 5 axis CNC operations and is a realistic way of cutting tool feeds and speeds to reduce cycle times. The Basics of CNC Simulator .Fusion includes a growing suite of powerful toolpaths that can be run on 2D, 2.5D, 3-, 4-, and 5-axis machines. A subscription to Fusion includes access to a library of accurate 3D models of commonly used CNC machines to help with part .

CNC Machine Tools Learning System – Denford Micromill: teaches basic safety and operation of the CNC mill as well as programming fundamentals such as: linear interpolation, startup and shutdown blocks, tooling selection, locating .

Written in a simple, easy-to-understand language by a skilled programmer with many years of experience teaching CNC machining to industry and in the classroom, this new edition offers a new chapter on feature-based Machining using Siemens, plus a new chapter featuring Fanuc NC guide I programming.CAD/CAM software is used to translate computer-aided design (CAD) to manufacturing workpieces with computer-aided manufacturing (CAM) on your CNC machine. Mastercam offers CAD/CAM software tools for a variety of CNC programming needs, from basic to complex.

list of cnc programming software

homemade cnc machine software

bt junction box types

An all-in-one CNC software solution for your business so you can start carving in minutes. START A 30 DAY FREE TRIAL Login to Easel . 3D in Easel Pro allows you to earn more money from your machine and take your business to the next level with unique, high-quality carvings. With the click of a button, import STL files and watch 3D designs .

CAD software or a programmer creates a 3D model à CAM software OR a programmer interprets the CAD model, optimizes and applies toolpaths, and writes the G-code for the CNC machine à CNC machine uses G-code to direct its cutting. The vast majority of shops have done away with manually writing G-code.

Vectric CNC software is designed to make cutting parts on a CNC an enjoyable and productive experience, with the combination of power and simplicity. English. Vectric. . The ‘Desktop’ edition is designed for small CNC machines, aimed at hobby or non-production environments, while the 'Pro' edition includes unlimited job and toolpath size . Easel is a highly intuitive all-in-one free engraving software for CNC router machines that supports CAD, CAM, and CNC control. It boasts a variety of high-quality and intuitive drawing tools, including fonts, templates, and image tracing. In addition, you can preview your designs in HD and 3D, and then autogenerate toolpaths in either 2D or 3D.

The CNC Machine Operator Academy, build knowledge and skills to manufacture precision parts and products. You’re hands-on in our modern labs, creating 3-D parts using modeling software. . Machine Operator Program, set up, and operate Computer Numerical Control (CNC) machinery to produce parts. Mill Machinist Operate milling machines . Types of CNC Programming. We’ve listed out the three main CNC programming methods that are beneficial to most types of CNC machining — although there are nicher types that exist, too. 1. Manual Manual programming is exactly how it sounds and is done by a programmer manually inputting information into the CNC machine’s control console.

Written in simple, easy-to-understand language by skilled programmers with years of experience teaching CNC machining to the industry and in formal education settings, this new edition provides full descriptions of many operation and programming functions and illustrates their practical applications through examples. It provides in-depth information on how to program . How To Program a Plasma CNC Machine. Once you’re ready to program your plasma CNC machine, you’ll need to start by setting up the machine’s parameters. That includes selecting the material type and thickness, as this will determine the cutting speed and power required. Input the shape or design dimensions that the machine will cut. Load . Send programs to CNC machine Join us! eMastercam - your online source for all things Mastercam. Together, we are the strongest Mastercam community on the web with over 56,000 members, and our online store offers a wide selection of training materials for all applications and skill levels. Useful Links .

CNC Software-Related Keywords= 43/2600 = 1.6% roughly. CNC Software related keywords= 46/2600= 1.7 % roughly . ميتا الوصف: Explore CNC software rated from beginner to expert, and get a glimpse of their functionalities, applications, and how nicely they integrate into the whole machining process. The right CNC software will be of use regardless if you are a hobbyist or in .Machine Link™ can be configured to communicate with any machine in your shop. It can also be configured for an unlimited number of different machine controls. Simply select the control name from the drop down list box and Machine Link™ is ready to send and receive CNC program files using the communication parameters associated with that CNC machine tool.Computer Numerical Control (CNC) Programming and Operations Associate in Applied Science. This program teaches machine controls, setting tools, machine limits and capabilities; creating, editing and debugging high-tech machine programs; utilizing high-end CAD/CAM software; basic 3-axis to multi-axis machining and turning centers; and Rapid Prototyping.

CAMWorks® best-in-class CNC programming solution enables users to program smarter and machine faster. About HCL CAMWorks CAMWorks® with Machining Intelligence is the most advanced CAM programming software available for getting products to market faster, more efficiently and within budget. The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions.CNC machining classes offer a comprehensive immersion in the understanding and application of CNC technology. You will focus on machine operation, programming, setup, blueprint reading and quality control techniques — all of which are crucial for manufacturing precise components.

The CNC Technology certificate program offers training for both new and experienced machinists. Individuals new to CNC can complete the entire program sequence to gain the insight and skills necessary to obtain an entry-level CNC operator position. . Ability to read traditional metrology tools utilized in the machining environment (e.g .

Introduction to CNC: Understand the basics of CNC machining, its applications, and its significance in modern manufacturing. CNC Machine Components: Explore the key components of CNC machines and their functions, from the controller to the cutting tools. G-code and M-code: Grasp the essential programming languages used in CNC machining.

SOLIDWORKS CAM comes with an included list for some of the more standard machines (like the Haas VF-3 I used to create my program) but custom post processors can be written by TriMech to let you use SOLIDWORKS CAM with your specific CNC Machine. When I post process my CNC program, it will convert all of my operations and toolpaths into useable . Once the CAM software creates the program, the code for the CNC machine — referred to as G-code — can be generated and post-processed to function on specific CNC firmware. G-code is a machine-readable list of instructions that tells the machine where and at what speed to move the tool. G-code used to be generated by machinists one step at a .

By programming CNC machines to perform in-process measurements, monitor tool wear, and adjust machining parameters dynamically, manufacturers can ensure that each part meets the highest standards of quality and accuracy. Additionally, CNC programming software enables programmers to simulate and optimize machining processes virtually, allowing .CNC machines require a lot of software to get them running and it's possible to run up a pretty big bill buying commercial options. In fact, it's easy to spend more on software than you did on your CNC router. Luckily, there are many options for free CNC software available. Whether you have a big industrial machine or a little CNC 3018 machine .

cnc programming for dummies

cnc milling machine programming software

It is good to use 0.023- or 0.025-inch diameter filler wire with MIG welding. As a rule of thumb, use a wire diameter that is thinner than the base metal. Typical welding parameters for MIG welding using 0.025 inches (0.6 mm) and 0.030 inches (0.8 mm) wire are .

programs for cnc machines|top 10 cnc programming software