atc full form in cnc machine What does ATC mean? Automatic Tool Changer (ATC) is a mechanism allowing Computer Numerical Control (CNC) machines to switch cutting tools without operator intervention. Learn how to properly wire a lighting junction box for safe and efficient electrical connections. Step-by-step guide for professional results.

0 · what is an atc machine

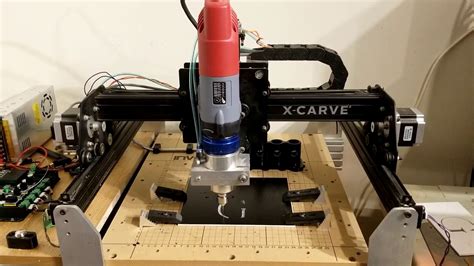

1 · cnc tool changer

2 · cnc machine atc

3 · cnc automatic tool changer chain

4 · automatic tool changer cnc machine

5 · atc drum type changer

We buy ALL used commercial kitchen equipment. Anywhere in Singapore. Stainless steel tables, cabinets, sinks & shelving, chillers and freezers, glass display cabinets, pizza ovens, grillers, broilers, combi ovens and everything .

In machining, an automatic tool changer (ATC) is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATCs change tools rapidly, reducing non-productive time. They are generally used to improve the capacity of the machines to work with a number of tools. They are also used to change worn out or broken tools. They are one more step towards complete automation. A CNC Automatic Tool Changer, or ATC, is a sophisticated component built into many CNC machines to help streamline the machining process by automating the change of tools. It allows CNC machines to .

Automatic Tool Changer (ATC) is a feature in CNC machines that enables the automatic change of cutting tools without the need for operator intervention. The ATC system consists of a magazine that holds a variety of .

circular sheet metal cutter

What does ATC mean? Automatic Tool Changer (ATC) is a mechanism allowing Computer Numerical Control (CNC) machines to switch cutting tools without operator intervention.An Automatic Tool Changer (ATC) is a device used in CNC machines to automatically change tools during the machining process. It eliminates the need for manual intervention, allowing for .An automatic tool changer often referred to as an ATC, is used to improve both the production and the tool carrying capacity of a computerised numerical control or CNC machine tool. It does this by allowing the machine to work with various . Types of automatic tool changers (ATC) An automatic tool changer is an accessory that is part of those milling machines equipped with a numerical control and which allows that the change of tools in the milling head is carried .

By streamlining the process of switching tools during machining operations, ATCs save valuable time, reduce labour costs, and increase the overall output. The Tekcel ATC is integrated into .

what is an atc machine

It is a device that provides tool storage and tool change requirements required in the process of automatic machining. Its automatic tool changing mechanism and ATC, which can store multiple tools, have changed .What is an automatic tool changer? The automatic tool changer is called ATC for short, and it can also be called a tool magazine. It is the main core component of the CNC machining center machine.

In machining, an automatic tool changer (ATC) is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATCs change tools rapidly, reducing non-productive time. A CNC Automatic Tool Changer, or ATC, is a sophisticated component built into many CNC machines to help streamline the machining process by automating the change of tools. It allows CNC machines to operate with almost no human intervention and reduces the time it usually takes to switch out the tools manually.

Automatic Tool Changer (ATC) is a feature in CNC machines that enables the automatic change of cutting tools without the need for operator intervention. The ATC system consists of a magazine that holds a variety of tools, a tool changing mechanism, and a controller that manages the tool changes.

What does ATC mean? Automatic Tool Changer (ATC) is a mechanism allowing Computer Numerical Control (CNC) machines to switch cutting tools without operator intervention.An Automatic Tool Changer (ATC) is a device used in CNC machines to automatically change tools during the machining process. It eliminates the need for manual intervention, allowing for continuous operation and increased productivity. The ATC system typically includes a tool magazine, a tool carousel or changer, and a tool-holding spindle.

An automatic tool changer often referred to as an ATC, is used to improve both the production and the tool carrying capacity of a computerised numerical control or CNC machine tool. It does this by allowing the machine to work with various different tools.

Types of automatic tool changers (ATC) An automatic tool changer is an accessory that is part of those milling machines equipped with a numerical control and which allows that the change of tools in the milling head is carried out in a programmed way and without the intervention of an operator.By streamlining the process of switching tools during machining operations, ATCs save valuable time, reduce labour costs, and increase the overall output. The Tekcel ATC is integrated into all their CNC (Computer Numerical Control) machines, allowing . It is a device that provides tool storage and tool change requirements required in the process of automatic machining. Its automatic tool changing mechanism and ATC, which can store multiple tools, have changed the traditional human-oriented production mode.

What is an automatic tool changer? The automatic tool changer is called ATC for short, and it can also be called a tool magazine. It is the main core component of the CNC machining center machine.In machining, an automatic tool changer (ATC) is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATCs change tools rapidly, reducing non-productive time.

citizen cnc swiss screw machine

A CNC Automatic Tool Changer, or ATC, is a sophisticated component built into many CNC machines to help streamline the machining process by automating the change of tools. It allows CNC machines to operate with almost no human intervention and reduces the time it usually takes to switch out the tools manually. Automatic Tool Changer (ATC) is a feature in CNC machines that enables the automatic change of cutting tools without the need for operator intervention. The ATC system consists of a magazine that holds a variety of tools, a tool changing mechanism, and a controller that manages the tool changes.What does ATC mean? Automatic Tool Changer (ATC) is a mechanism allowing Computer Numerical Control (CNC) machines to switch cutting tools without operator intervention.An Automatic Tool Changer (ATC) is a device used in CNC machines to automatically change tools during the machining process. It eliminates the need for manual intervention, allowing for continuous operation and increased productivity. The ATC system typically includes a tool magazine, a tool carousel or changer, and a tool-holding spindle.

An automatic tool changer often referred to as an ATC, is used to improve both the production and the tool carrying capacity of a computerised numerical control or CNC machine tool. It does this by allowing the machine to work with various different tools. Types of automatic tool changers (ATC) An automatic tool changer is an accessory that is part of those milling machines equipped with a numerical control and which allows that the change of tools in the milling head is carried out in a programmed way and without the intervention of an operator.

cnc tool changer

cnc machine atc

By streamlining the process of switching tools during machining operations, ATCs save valuable time, reduce labour costs, and increase the overall output. The Tekcel ATC is integrated into all their CNC (Computer Numerical Control) machines, allowing .

city sheet metal ltd

cnc automatic tool changer chain

Shop our used metal storage cabinets with doors selection from top sellers and makers around the world. Global shipping available.

atc full form in cnc machine|cnc machine atc