cnc machine programming language CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

Sheet metal fabrication is a simple yet diverse manufacturing operation. For product designers, companies and entrepreneurs that are new to interfacing with sheet metal .

0 · types of cnc programming

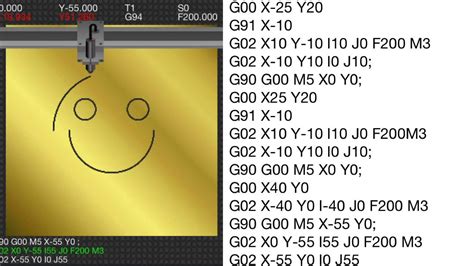

1 · simple g code program

2 · how to program cnc machines

3 · g code for cnc machine

4 · cnc programming languages list

5 · cnc programming for beginners

6 · cnc milling machine programming

7 · basics of cnc programming

What color metal roof is best? The best matches include black and red, as well as bare metal. Yellow buildings are beautiful and sunny, but the roof needs to contrast with the bright color. Muted shades are going to be the best bet here, so stick with things like black, brown, and gray.

types of cnc programming

Our guide delves into G Code for geometric moves and M Code for machine functions, essential for CNC programming. CNC machines rely on G Code and M Code, foundational programming languages. G Code controls .G-code is a programming language used to control computer numerical control (CNC) machines. It consists of a series of commands or instructions that tell the CAM CNC machine how to .

simple g code program

For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how .

G-Code, the core language of CNC (Computer Numerical Control) machines, is a standardized programming language that instructs machine tools how to move and operate. It consists of alphanumeric codes that represent .

G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete .Looking to get started in CNC machine programming? Learn the basics of G-Code commands, M-code and how CAM systems can help improve your workshop’s efficiencies.

Our guide delves into G Code for geometric moves and M Code for machine functions, essential for CNC programming. CNC machines rely on G Code and M Code, foundational programming languages. G Code controls movement, while M Code manages machine functions.

how to program cnc machines

G-code is a programming language used to control computer numerical control (CNC) machines. It consists of a series of commands or instructions that tell the CAM CNC machine how to move, position, and operate its various components, such as . Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – . For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how it’s made, and how to read it will make that decision easier. G-Code, the core language of CNC (Computer Numerical Control) machines, is a standardized programming language that instructs machine tools how to move and operate. It consists of alphanumeric codes that represent specific machine functions, such as tool movement, spindle speed, and coolant control.

G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications.

Looking to get started in CNC machine programming? Learn the basics of G-Code commands, M-code and how CAM systems can help improve your workshop’s efficiencies.

While most CNC machines use G-code as the standard programming language for controlling operations, not all CNC machines rely exclusively on it. Some machines may use proprietary programming languages or other formats, depending on .

Our guide delves into G Code for geometric moves and M Code for machine functions, essential for CNC programming. CNC machines rely on G Code and M Code, foundational programming languages. G Code controls movement, while M Code manages machine functions.G-code is a programming language used to control computer numerical control (CNC) machines. It consists of a series of commands or instructions that tell the CAM CNC machine how to move, position, and operate its various components, such as . Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – . For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how it’s made, and how to read it will make that decision easier.

G-Code, the core language of CNC (Computer Numerical Control) machines, is a standardized programming language that instructs machine tools how to move and operate. It consists of alphanumeric codes that represent specific machine functions, such as tool movement, spindle speed, and coolant control. G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications.Looking to get started in CNC machine programming? Learn the basics of G-Code commands, M-code and how CAM systems can help improve your workshop’s efficiencies.

china brass cnc turned parts suppliers

g code for cnc machine

cnc programming languages list

cnc programming for beginners

Some call them 'anti-rattle clips or retention clips. They keep your pads within a certain tolerance of variance regarding the touch points on the disk. As well, they prevent the pads from rattling as you drive down the road and the pucks within your calipers are retracted just a .

cnc machine programming language|types of cnc programming