duct sheet metal thickness Considering galvanized sheet thickness tolerances, the minimum duct thickness is between 0.4712 mm (0.0187 in) and 0.6312 mm (0.0247 in). In practice, the minimum duct thickness is 0.5 mm. In some occasions, the . At a foundational level, a canned cycle is designed to reduce the volume of G-code a programmer has to write. G-code, the language of CNC machines, dictates every movement and function of the machine. For repetitive tasks, writing out each line of G-code can be tedious and error-prone.

0 · smacna sheet metal gauge chart

1 · sheet metal duct weight calculator

2 · hvac ductwork sheet metal fabrication

3 · duct size and gauge chart

4 · duct gauge weight kg m2

5 · duct gauge weight chart

6 · duct gauge thickness chart

7 · duct gauge chart sheet metal

The in-ground installation for CANTEX PVC junction boxes is also simple, but always be sure to follow all national and regional electrical codes when .

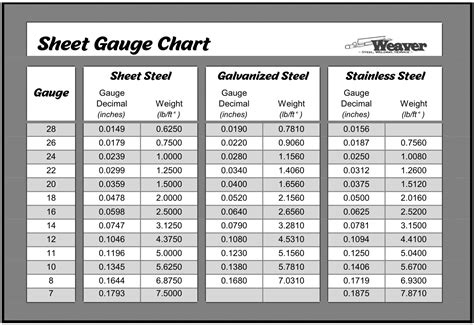

Sheet metal gauge determines the thickness and strength of HVAC ductwork, impacting its ability to withstand pressure and airflow. Choosing the right thickness is crucial for ensuring compliance with safety regulations . Ductwork sheet metal gauges: Thickness of sheet metal used in ductwork. Minimum thickness of metal duct material shall be as listed in Table M1601.1.1(2). Galvanized steel shall conform to ASTM A 653. Metallic ducts shall be fabricated in .“STD” denotes standard (nonvariable volume) air duct construction requirements (regardless of actual velocity level) for compliance with this document for all cases in which the designer .

Considering galvanized sheet thickness tolerances, the minimum duct thickness is between 0.4712 mm (0.0187 in) and 0.6312 mm (0.0247 in). In practice, the minimum duct thickness is 0.5 mm. In some occasions, the . A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for . Sheet sizes also come in multiple thicknesses. Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge . Sheet metal gauge determines the thickness and strength of HVAC ductwork, impacting its ability to withstand pressure and airflow. Choosing the right thickness is crucial for ensuring compliance with safety regulations and meeting minimum requirements set by codes.

Ductwork sheet metal gauges: Thickness of sheet metal used in ductwork. Minimum thickness of metal duct material shall be as listed in Table M1601.1.1(2). Galvanized steel shall conform to ASTM A 653. Metallic ducts shall be fabricated in accordance with SMACNA Duct Construction Standards Metal and Flexible.“STD” denotes standard (nonvariable volume) air duct construction requirements (regardless of actual velocity level) for compliance with this document for all cases in which the designer does not designate the pressure classification for the duct system independent of fan static rating. Below is a table of GI duct thicknesses based on different duct sizes: Galvanized metal sheets used for ducts as well as other equivalent applications must comply with the JIS G3302 standard. If they do, a mill certificate shall be provided.

smacna sheet metal gauge chart

Considering galvanized sheet thickness tolerances, the minimum duct thickness is between 0.4712 mm (0.0187 in) and 0.6312 mm (0.0247 in). In practice, the minimum duct thickness is 0.5 mm. In some occasions, the minimum duct thickness is 1.2 mm.

A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for accurate material selection and processing. Sheet sizes also come in multiple thicknesses. Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker).

Use the Sheet Metal Gauge Calculator today and experience the difference it can make in your work. The size of a gauge is a numerical value that signifies the thickness of a sheet metal. The larger the gauge number, the thinner the sheet metal.The thinnest acceptable sheet metal for ductwork used in a single dwelling is 28 gage or 0.013 and 0.018 inches for galvanized and aluminum, respectively. This measurement is for around duct smaller than 12 inches in diameter and a rectangular section no bigger than 8 inches. Sheet metal gauge determines the thickness and strength of HVAC ductwork, impacting its ability to withstand pressure and airflow. Choosing the right thickness is crucial for ensuring compliance with safety regulations and meeting minimum requirements set by codes. Ductwork sheet metal gauges: Thickness of sheet metal used in ductwork.

sheet metal duct weight calculator

Minimum thickness of metal duct material shall be as listed in Table M1601.1.1(2). Galvanized steel shall conform to ASTM A 653. Metallic ducts shall be fabricated in accordance with SMACNA Duct Construction Standards Metal and Flexible.

“STD” denotes standard (nonvariable volume) air duct construction requirements (regardless of actual velocity level) for compliance with this document for all cases in which the designer does not designate the pressure classification for the duct system independent of fan static rating. Below is a table of GI duct thicknesses based on different duct sizes: Galvanized metal sheets used for ducts as well as other equivalent applications must comply with the JIS G3302 standard. If they do, a mill certificate shall be provided.

depth to nail electric box new construction

Considering galvanized sheet thickness tolerances, the minimum duct thickness is between 0.4712 mm (0.0187 in) and 0.6312 mm (0.0247 in). In practice, the minimum duct thickness is 0.5 mm. In some occasions, the minimum duct thickness is 1.2 mm. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for accurate material selection and processing.

Sheet sizes also come in multiple thicknesses. Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker).Use the Sheet Metal Gauge Calculator today and experience the difference it can make in your work. The size of a gauge is a numerical value that signifies the thickness of a sheet metal. The larger the gauge number, the thinner the sheet metal.

hvac ductwork sheet metal fabrication

duct size and gauge chart

duct gauge weight kg m2

duct gauge weight chart

What does a CNC operator do? A CNC operator pushes buttons to keep the CNC machines running while performing basic inspection of the machined parts. As an entry-level position, all of the skills necessary for a CNC operator to possess would be taught to a .

duct sheet metal thickness|duct size and gauge chart