electric junction box size You must size pull boxes, junction boxes, and conduit bodies large enough so a . How to Weld Auto Body Sheet Metal With a TIG Welder. The best two electrodes for welding auto body sheet metal are either ceriated tungsten or thoriated tungsten.

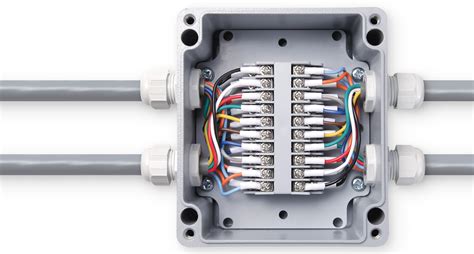

0 · types of electrical junction boxes

1 · standard electrical junction box size

2 · standard electrical box size chart

3 · nec junction box size chart

4 · electrical pull box size chart

5 · electrical junction box size chart

6 · electrical junction box size calculator

7 · electrical box sizing chart

Industrial Metal Supply stocks a broad range of metal materials, including aluminum, steel, stainless steel, copper and brass, and specialty metals. We also provide other services, including laser cutting, metal contracts, broker buying, and material management.

Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger.You must size pull boxes, junction boxes, and conduit bodies large enough so a . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For .

According to NEC 314.16 (B), calculate the box fill units based on the conductor sizes and types. Each conductor, device, and fitting has a specific fill unit value. Use Table 314.16 (B) to find the volume allowances for each component. . The National Electrical Code has published a chart that determines a junction box’s correct size, based on the number and size of the conductors it must accommodate. The size of a conductor is expressed as AWG (American . Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger.

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. Wondering how to size a junction box? Find out how to use the NEC code to determine the size of the junction box that your application requires.

types of electrical junction boxes

According to NEC 314.16 (B), calculate the box fill units based on the conductor sizes and types. Each conductor, device, and fitting has a specific fill unit value. Use Table 314.16 (B) to find the volume allowances for each component. Conductors: Count each conductor that originates outside and terminates or passes through the box. The National Electrical Code has published a chart that determines a junction box’s correct size, based on the number and size of the conductors it must accommodate. The size of a conductor is expressed as AWG (American Wire Gauge); the .By accurately sizing your junction box, you ensure compliance with safety standards, prevent potential electrical issues, and optimize space usage. The calculator takes into account several factors, such as the type of conduit, conductor size, and the number of conductors.

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull.Section 370.16 outlines requirements for sizing boxes containing conductors 6 AWG or smaller. Remember, specific dimensions are used to calculate the box size.

china cnc machining brass parts

Effortlessly calculate the required electrical junction box size for your wiring project using our Electrical Junction Box Size Calculator. Input the number of conductors and select the box type to get accurate results. Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

Wondering how to size a junction box? Find out how to use the NEC code to determine the size of the junction box that your application requires.According to NEC 314.16 (B), calculate the box fill units based on the conductor sizes and types. Each conductor, device, and fitting has a specific fill unit value. Use Table 314.16 (B) to find the volume allowances for each component. Conductors: Count each conductor that originates outside and terminates or passes through the box. The National Electrical Code has published a chart that determines a junction box’s correct size, based on the number and size of the conductors it must accommodate. The size of a conductor is expressed as AWG (American Wire Gauge); the .

By accurately sizing your junction box, you ensure compliance with safety standards, prevent potential electrical issues, and optimize space usage. The calculator takes into account several factors, such as the type of conduit, conductor size, and the number of conductors.

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull.Section 370.16 outlines requirements for sizing boxes containing conductors 6 AWG or smaller. Remember, specific dimensions are used to calculate the box size.

standard electrical junction box size

china cnc machine purchase outsourcing in

china cnc machining components factory

Nevertheless, even the best-designed metal sheet can get undesirable gaps or holes during work. Here are some tips and tricks to deal with sheet metal gaps/holes: Placing sheet metal flush to each other enhances flawless fusion in short bursts while allowing them to cool in between. Continue in short circular motions until it is well done.

electric junction box size|standard electrical box size chart