add sheet metal tool to solidworks If the forming tool has radii that are pushed into the sheet metal body, then the . Discover 35 creative, smart and practical repurposing ideas for your cardboard boxes. Follow our projects and get creative today.

0 · sheet metal modeling in SolidWorks

1 · sheet metal in SolidWorks 2021

2 · sheet metal forming SolidWorks

3 · SolidWorks sheet metal toolbar

4 · SolidWorks sheet metal template

5 · SolidWorks sheet metal practice exercises

6 · SolidWorks sheet metal examples

7 · SolidWorks create sheet metal part

Here is a list of the 7 best flux core welders I recommend: 1. YesWelder 135AMP 110V Gasless MIG Welder. An excellent choice for beginners with automatic (“Synergic”) adjustability, and ideal to try other processes without breaking the bank.

The Bends PropertyManager allows you to convert a shelled part to a sheet metal part. Adding Sheet Metal Gussets. You can create sheet metal gussets with specific indents that go across bends. Sheet Metal Tabs. The depth of a tab feature is automatically set to the thickness of the .

You can create a sheet metal part by converting a solid or surface body using .Opening the Model and Inserting a Forming Tool. Next, you open a sheet metal part .

If the forming tool has radii that are pushed into the sheet metal body, then the .When designing sheet metal parts, the order preference for use of feature tools .

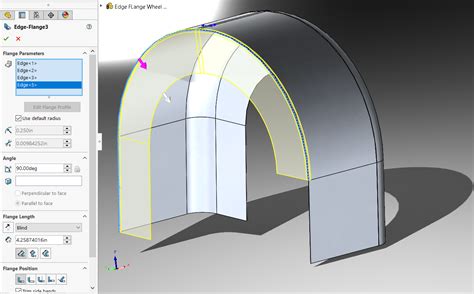

You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features .Opening the Model and Inserting a Forming Tool. Next, you open a sheet metal part and add the formed louver from the Design Library. Specifying the Louvers. Next, you specify the louver . SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create . In this quick tutorial, we explain how to use some of the sheet metal tools in SOLIDWORKS, specifically the Fold and Unfold tools. First, let’s set up our base flange, being sure to have a fully defined sketch to start. After .

If the forming tool has radii that are pushed into the sheet metal body, then the forming tool will fail when the concave radius is smaller than the material thickness. In this case the radius that .

Learn solidworks basic tutorial for beginner how to add sheet metal tab and toolbar#solidworks#howto#mufasucad This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a .When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the .

The Bends PropertyManager allows you to convert a shelled part to a sheet metal part. Adding Sheet Metal Gussets. You can create sheet metal gussets with specific indents that go across bends. Sheet Metal Tabs. The depth of a tab feature is automatically set to the thickness of the sheet metal part.

You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features to it. Use the Convert to Sheet Metal tool with: Solid or surface bodies that have: No shells or fillets; Either a shell or fillets; Both a shell and fillets .Opening the Model and Inserting a Forming Tool. Next, you open a sheet metal part and add the formed louver from the Design Library. Specifying the Louvers. Next, you specify the louver rotation angle and insert two more identical louvers. Replacing Forming Tools. Next, you replace the louver forming tool with an extruded hole forming tool. SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create sheet metal designs with several different methods. Step by step tutorial post about how to use solidworks sheet metal feature tool for making sheetmetal tools and various applications.

In this quick tutorial, we explain how to use some of the sheet metal tools in SOLIDWORKS, specifically the Fold and Unfold tools. First, let’s set up our base flange, being sure to have a fully defined sketch to start. After creating a base flange, find the Fold and Unfold tools in the Sheet Metal tab in the CommandManager. It is often much .If the forming tool has radii that are pushed into the sheet metal body, then the forming tool will fail when the concave radius is smaller than the material thickness. In this case the radius that gets pushed into the sheet metal body becomes negative and forces the tool to fail. Learn solidworks basic tutorial for beginner how to add sheet metal tab and toolbar#solidworks#howto#mufasucad

rectangular to round junction box

This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video will help you master sheet metal design using SolidWorks, covering essential techniques and tips to boost your productivity.When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the Insert Bends feature. 3. Use the Convert to Sheet Metal feature. When using the Insert Bends or Convert to Sheet Metal features, apply the features as earlyThe Bends PropertyManager allows you to convert a shelled part to a sheet metal part. Adding Sheet Metal Gussets. You can create sheet metal gussets with specific indents that go across bends. Sheet Metal Tabs. The depth of a tab feature is automatically set to the thickness of the sheet metal part.You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features to it. Use the Convert to Sheet Metal tool with: Solid or surface bodies that have: No shells or fillets; Either a shell or fillets; Both a shell and fillets .

Opening the Model and Inserting a Forming Tool. Next, you open a sheet metal part and add the formed louver from the Design Library. Specifying the Louvers. Next, you specify the louver rotation angle and insert two more identical louvers. Replacing Forming Tools. Next, you replace the louver forming tool with an extruded hole forming tool. SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create sheet metal designs with several different methods. Step by step tutorial post about how to use solidworks sheet metal feature tool for making sheetmetal tools and various applications.

In this quick tutorial, we explain how to use some of the sheet metal tools in SOLIDWORKS, specifically the Fold and Unfold tools. First, let’s set up our base flange, being sure to have a fully defined sketch to start. After creating a base flange, find the Fold and Unfold tools in the Sheet Metal tab in the CommandManager. It is often much .If the forming tool has radii that are pushed into the sheet metal body, then the forming tool will fail when the concave radius is smaller than the material thickness. In this case the radius that gets pushed into the sheet metal body becomes negative and forces the tool to fail. Learn solidworks basic tutorial for beginner how to add sheet metal tab and toolbar#solidworks#howto#mufasucad

This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video will help you master sheet metal design using SolidWorks, covering essential techniques and tips to boost your productivity.

sheet metal modeling in SolidWorks

Common options include steel, aluminum, and galvanized steel, each with its own advantages in terms of strength and corrosion resistance. Additionally, consider factors such as gauge thickness and finish to ensure a seamless integration with your car’s existing bodywork.

add sheet metal tool to solidworks|SolidWorks sheet metal toolbar