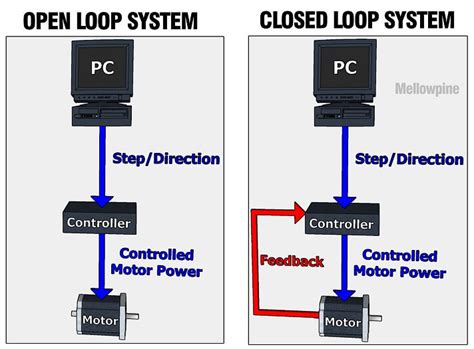

closed loop control system in cnc machine The open and closed loop system describes the two primary types of CNC control systems. Open and closed loop describes the control process of a system. Open loop refers to a system where the communication between the controller system and the motor is one way. What does a Metal Fabricator do and what are their responsibilities? Explore the role, responsibilities, and skills of metal fabricators. Dive into comparisons of different metal .

0 · open loop vs closed motor

1 · open loop stepper motor

2 · nema 34 stepper motor controller

3 · cnc closed loop system

4 · closed loop vs open cnc

5 · closed loop steppers

6 · centroid controller for cnc mill

7 · buildbotics cnc controller

In this guide, I’ll compare all of the DIY CNC routers I’ve tested across their key strengths and limitations – like price, ease of use, speed, and power – so you can make a confident choice. 1. Sainsmart Genmitsu 3018 PRO — Best Cheap Pick. Open-source? Yes. One of the best DIY CNC routers under $300. Offers a large build area.

The open and closed loop system describes the two primary types of CNC control systems. Open and closed loop describes the control process of a system. Open loop refers to a system where the communication between the controller . How Does the Closed Loop System Work in CNC? The open and closed loop system describes the two primary types of CNC control systems. Open and closed loop describes the control process of a system. Open loop refers to a system where the communication between the controller system and the motor is one way. A closed-loop control system, also known as a feedback control system, uses the concept of an open-loop control system as its forward path but adds one or more feedback loops between its input signal and output signal.

How Does the Closed Loop System Work in CNC? In this video, we dive deep into the fundamental concepts of CNC machining, focusing on the open-loop and closed-loop control systems. Learn how stepper moto.

Closed-loop CNC machining uses feedback from Renishaw Central to update tool offsets and variables, maintaining process control. This extends the usual functions of in-machine tool setting and spindle probes, which now also send data to Renishaw Central.Learn about steppers, servos, closed-loop, and open-loop systems for CNC mini mills. Find the best option for your project.There are about five types of CNC Controllers based on axes, including motion-type CNC systems, loop-control CNC systems, and several axis-type CNC control systems. Motion-type CNC systems are further categorized into two main types: contouring control systems.The present invention will improve the performance of Computer-Numerically-Controlled (CNC) equipment by incorporating a closed-loop control system to vary cut parameters such as speeds.

This paper conducts and models and simulates the closed-loop control system of large precision machining machines. The software used for the simulation is Matlab and Simulink. The simulation controller uses a PID controller.A closed loop system is more complex than an open loop system because it relies on a controller and includes additional components such as an amplifier and feedback mechanisms. Unlike an open loop system, which simply executes commands, a closed loop .The open and closed loop system describes the two primary types of CNC control systems. Open and closed loop describes the control process of a system. Open loop refers to a system where the communication between the controller system and the motor is one way. A closed-loop control system, also known as a feedback control system, uses the concept of an open-loop control system as its forward path but adds one or more feedback loops between its input signal and output signal.

How Does the Closed Loop System Work in CNC?

open loop vs closed motor

open loop stepper motor

In this video, we dive deep into the fundamental concepts of CNC machining, focusing on the open-loop and closed-loop control systems. Learn how stepper moto. Closed-loop CNC machining uses feedback from Renishaw Central to update tool offsets and variables, maintaining process control. This extends the usual functions of in-machine tool setting and spindle probes, which now also send data to Renishaw Central.

Learn about steppers, servos, closed-loop, and open-loop systems for CNC mini mills. Find the best option for your project.

There are about five types of CNC Controllers based on axes, including motion-type CNC systems, loop-control CNC systems, and several axis-type CNC control systems. Motion-type CNC systems are further categorized into two main types: contouring control systems.The present invention will improve the performance of Computer-Numerically-Controlled (CNC) equipment by incorporating a closed-loop control system to vary cut parameters such as speeds.This paper conducts and models and simulates the closed-loop control system of large precision machining machines. The software used for the simulation is Matlab and Simulink. The simulation controller uses a PID controller.

nema 34 stepper motor controller

electrical enclosure sdn bhd

$21.99

closed loop control system in cnc machine|closed loop vs open cnc