fabrication of metal matrix composites pdf This book brings in the elements of the manufacturing of metal matrix . Welding is the process of joining metal together using a combination of heat and pressure until both elements become molten. Yankee sheet metal makes use of TIG and MIG welding, two electrical arc welding processes.

0 · processing of metal matrix composites

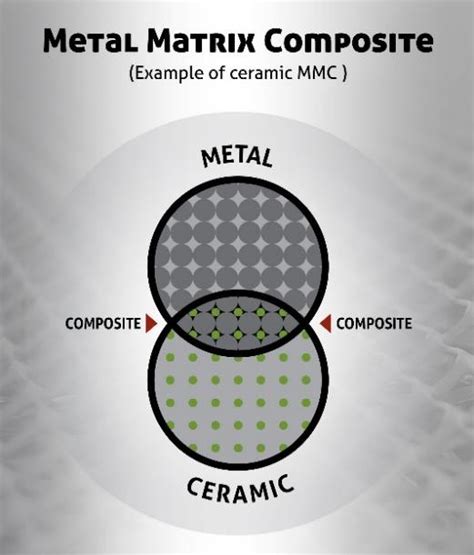

1 · metal matrix composites mmc

2 · metal matrix composites examples

3 · metal matrix composite wallpaper

4 · metal matrix composite properties

5 · metal matrix composite application

6 · classification of metal matrix composites

7 · aluminium metal matrix composites journals

Research by the RAC found that 57 percent of drivers are in favour of box junctions being enforced. However, it has also discovered evidence of major design flaws in how yellow box junctions.

Steel matrix composites were produced using 316L/ poly carbo silane (PCS) system via a novel semi. powder metallurgy method includes spark plasma sintering (SPS) .© 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP .This book brings in the elements of the manufacturing of metal matrix .This paper presents an overview of aluminium based metal matrix .

processing of metal matrix composites

metal matrix composites mmc

The replacement of conventional materials by metal matrix composite is increasing exponentially by virtue of its improved features like strength to weight ratio, hardness, stiffness, . This book brings in the elements of the manufacturing of metal matrix composites with a detailed focus on its fabrication, production, and 3D printing.Metal matrix composite materials can be produced by many different techniques. The focus of the selection of suitable process engineering is the desired kind, quantity and distribution of the .

Surface metal matrix composites offer good surface properties while retaining toughness and ductility of the metal matrix in comparison with conventional MMCs [17], [18]. .

The growing demand for lightweight and high-strength materials in the aerospace and automotive industries, as well as the need for highly conductive materials such as heat sinks, electrodes . Metal matrix composites (MMCs) are essential materials in various industries due to superior properties, such as high strength-to-weight ratios, better corrosion resistance, . This paper presents an overview of aluminium based metal matrix composites, processing of composites and stir casting process, process parameter of stir casting process, research work in .

how to protect electrical box from moisture

metal matrix composites examples

how to punch out holes in electrical box

This work investigates the microstructure, mechanical characteristics, and texture evolution of friction stir welding (FSW) of AA6061-T6 metal matrix composites (MMCs) .Metal Matrix Composites FINDINGS Metal matrix composites (MMCs) usually con-sist of a low-density metal, such as aluminum or magnesium, reinforced with particulate or fibers of a . Request PDF | A review on fabrication and characterization of copper metal matrix composite (CMMC) | The development towards the use of composites is rising rapidly to ameliorate the architectural .1. METAL MATRIX COMPOSITES Metal matrix composites (MMCs) comprise a relatively wide range of materials defined by the metal matrix, reinforcement type, and reinforcement geometry. In the area of the matrix, most metallic systems have been explored for use in metal matrix composites, including Al, Be, Mg, Ti, Fe, Ni, Co, and Ag.

Preface: This edited book entitled Metal Matrix Composite: Properties and Applications is the second volume in continuation to our first that provides in-depth concepts of metal matrix composites .

In this study, aluminum A356 (AlSi7Mg0.3) alloy matrix composites reinforced with various fractions (0.5, 1.0 and 1.5 wt%) of Al2O3 particles having two different particle sizes (nano- and micro .International journal of engineering research and technology, 2018. Aluminum metal matrix composites (AMMC) are becoming progressively very important materials in manufacturing industries and are generally preferred due to their enhanced mechanical properties like high strength, hardness, wear resistance, corrosion resistance, fatigue strength, compressive . Now a day’s metal matrix components are used in may industries and it finds the applications in many fields so, to make it as better performable materials. So,

It can be avoided by coating of reinforcements and by providing inert gas atmosphere during fabrication. Results conclude that metal matrix composites have high specific strength, greater strength . The nanoparticulate reinforced metal matrix composites (nPRMMCs) can further improve the ductility and fracture toughness of conventional microscale PRMMCs. PDF | Today, researchers across the world focus on sustainable products, and, accordingly, it is now imperative to develop sustainable MMCs. . and machinability of aluminum metal-matrix .

metal matrix composite wallpaper

The global mechanical behavior of metal or PMCs reinforced with randomly oriented short fibers (e.g., an Al/15 vol.% Al2O3 aluminium matrix composite and PMC with 20 or 30 vol.% glass-fibers) is .

PDF | Lightweight high-strength metal matrix nano-composites (MMNCs) can be used in a wide variety of applications, e.g., aerospace, automotive, and. | Find, read and cite all the research you .

A CuSiC MMC heatspreader will offer high thermal conductivity between 250 and 325 W/mK and corresponding adjustable thermal expansion coefficient between 8.0 and 12.5 ppm/°C. The primary challenge of CuSiC manufacture was to prevent reaction between copper and silicon carbide during high temperature densification, which dramatically degraded the .

Request PDF | Fabrication of metal matrix composites by a high-pressure centrifugal infiltration process | A new centrifugal casting process capable of achieving high pressures was developed for . Request PDF | Comprehensive review on fabrication methods of metal matrix composites and a case study on squeeze casting | Use of metal matrix composites (MMCs) in automobile and aerospace . D. IN SITU FABRICATION OF METAL MATRIX COMPOSITES In this process, a reinforcement phase is exhibited in the matrix phase as a outcome of of precipitation from the melt while it cools and Solidifies. E. TWO PHASE PROCESS Two phase process is like a spray deposition method but it

Processing of Metal Matrix Composites Metal matrix composite materials can be produced by many different techniques. The focus of the selection of suitable process engineering is the desired kind, quantity and distribution of the reinforcement components (particles and fibers), the matrix alloy and the application. For Progression of any materials cost minimization during manufacturing and operation are the main technology drivers. Nowadays copper and its alloy based composites are gaining importance in upcoming field of engineering. Since several years, copper-based metal matrix composites (MMCs) are gaining importance in production field.

The present study, based on the literature review, reinforcing material, processing route, mechanical and tribological properties of Mg based metal matrix composites containing single and multiple .

how to properly insulate a metal battery box

Materials are often selected for structural, aerospace and automotive applications because of better mechanical properties. In recent days development of Hybrid Metal Matrix Composites (HMMCs) has .SUMMERY: Metal matrix composite (MMC) bling (bladed ring) for gas-turbine’s compressor was developed. The bling was consist of monolithic titanium clad and hoop reinforced MMC core. The MMC core material was using titanium matrix coated fiber. The MMC core’s fabrication process included winding of matrix coated fiber (wire) to pre-form and hot press consolidation of .

The demand for lightweight material with high strength has led to the development of novel aluminium-based metal matrix composites. Uniformly dispersed nanoparticle-reinforced metal matrix .

Request PDF | Fabrication of metal matrix composites by metal injection molding—A review | Metal injection molding (MIM) is a near net-shape manufacturing technology that is capable of mass . Aluminium metal matrix composites (AMMCs) are the materials in which aluminium metal is used as matrix material reinforced with other materials i.e. mostly ceramics like S iC, Al 2 O 3 , B 4 C, Ti . The unique features of the process make it an attractive route for the fabrication of metal matrix composite materials. In this paper, the status of the research and development in fabricating metal matrix composites by MIM is reviewed, with a major focus on material systems, fabrication methods, resulting material properties and microstructures.

Metal Matrix Composites (MMCs) are widely utilized and preferred materials for high-tech applications such as aerospace, defense, and the automobile sector due to higher attributes in comparison .This book is the first of its kind to deal with fabrication processes of metal matrix composites (MMCs) theoretically, experimentally, systematically, and instructively. The theoretical bases of fabrication processes and recycling processes of MMCs are established in this volume.In today's competitive world need has been increased towards development of low cost, efficient, lightweight, corrosion resistive, highly reflectivity, tough, conducive materials. Aluminium alloy composites are well known for its better thermal

Yarlmetal produces several formed shapes to meet client specifications. Formed metal is used as an aesthetic option that is cost effective and easy to maintain. The ductility of metal makes this a versatile, practical choice and is preferred by architects, builders and designers.

fabrication of metal matrix composites pdf|classification of metal matrix composites