cnc machine inserts CNC (Computer Numerical Control) machining technology plays a pivotal role in modern manufacturing, and inserts, as a key tool in CNC machining, directly impact machining . For example, using angle iron for mezzanine handrail on modular conveyor systems. It’s much quicker to weld, paint, and because it’s lighter, it’s cheaper to ship. Just need to do a cost/value analysis to understand the benefits of each.

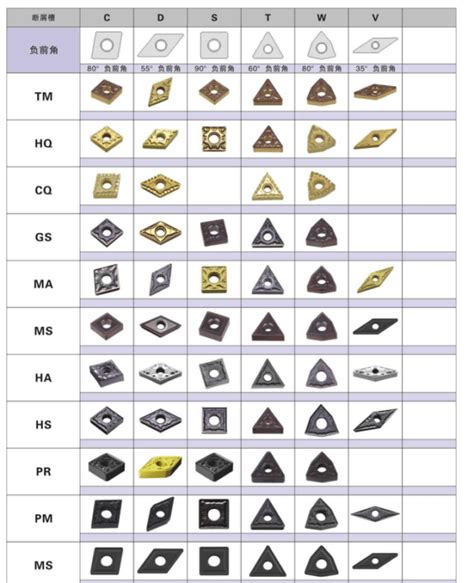

0 · types of inserts in cnc

1 · types of cutting inserts chart

2 · types of cnc turning inserts

3 · how to identify turning inserts

4 · cnc lathe insert chart

5 · cnc inserts and tooling

6 · cnc insert chart

7 · carbide insert for cnc

$1,499.00

In CNC machining, cutting inserts are one of the key elements that determine the efficiency and precision of the process. Learning about the different types of inserts, their uses, and specifications is essential for any CNC machine operator .

CNC inserts are small, replaceable cutting tools used in CNC machines to remove material from workpieces. These inserts are designed to be easily interchangeable, allowing operators to quickly replace worn or damaged .There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining . CNC (Computer Numerical Control) machining technology plays a pivotal role in modern manufacturing, and inserts, as a key tool in CNC machining, directly impact machining . Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and .

Discover a range of cutting-edge inserts designed for milling applications, offering efficiency, durability, and superior performance in metalworking processes. Find the perfect milling inserts to optimize your machining operations and achieve .In CNC machining, cutting inserts are one of the key elements that determine the efficiency and precision of the process. Learning about the different types of inserts, their uses, and specifications is essential for any CNC machine operator .

types of inserts in cnc

CNC inserts are small, replaceable cutting tools used in CNC machines to remove material from workpieces. These inserts are designed to be easily interchangeable, allowing operators to quickly replace worn or damaged cutting .There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance. CNC (Computer Numerical Control) machining technology plays a pivotal role in modern manufacturing, and inserts, as a key tool in CNC machining, directly impact machining efficiency and product quality. This article will detail the types, materials, machining methods, coatings, advantages, hardness, and lifespan of inserts. Types of Inserts

Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Understanding the material properties and machining conditions is crucial for .Discover a range of cutting-edge inserts designed for milling applications, offering efficiency, durability, and superior performance in metalworking processes. Find the perfect milling inserts to optimize your machining operations and achieve exceptional results.The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness. Choose the insert style (shape and size) based on the .Choose from our selection of cutting inserts, including carbide inserts for multiple materials, economy carbide inserts, and more. In stock and ready to ship.

As the first carbide insert and cutting tool manufacturer in the United States to purchase a CNC periphery, as well as top and bottom grinders for precision-ground milling, turning and boring inserts, Knight has earned its reputation as an industry innovator time .

In this extensive guide, we have covered the fundamentals of CNC turning inserts, explored the different types, materials, and coatings available, and provided valuable tips for selecting and using the right insert for optimal efficiency.In CNC machining, cutting inserts are one of the key elements that determine the efficiency and precision of the process. Learning about the different types of inserts, their uses, and specifications is essential for any CNC machine operator . CNC inserts are small, replaceable cutting tools used in CNC machines to remove material from workpieces. These inserts are designed to be easily interchangeable, allowing operators to quickly replace worn or damaged cutting .There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining performance.

CNC (Computer Numerical Control) machining technology plays a pivotal role in modern manufacturing, and inserts, as a key tool in CNC machining, directly impact machining efficiency and product quality. This article will detail the types, materials, machining methods, coatings, advantages, hardness, and lifespan of inserts. Types of Inserts Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Understanding the material properties and machining conditions is crucial for .

Discover a range of cutting-edge inserts designed for milling applications, offering efficiency, durability, and superior performance in metalworking processes. Find the perfect milling inserts to optimize your machining operations and achieve exceptional results.The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness. Choose the insert style (shape and size) based on the .Choose from our selection of cutting inserts, including carbide inserts for multiple materials, economy carbide inserts, and more. In stock and ready to ship.As the first carbide insert and cutting tool manufacturer in the United States to purchase a CNC periphery, as well as top and bottom grinders for precision-ground milling, turning and boring inserts, Knight has earned its reputation as an industry innovator time .

types of cutting inserts chart

Corner joint welding is a specialized process used to join two pieces of material that are connected at a 90-degree angle, creating an L-shape. Experienced welders know that many techniques are similar in the way they look when the weld is complete and in terms of the positioning of the material.

cnc machine inserts|types of inserts in cnc