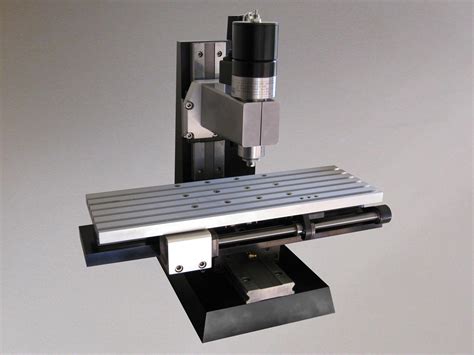

diy wood cnc machine Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __ But are knockouts the same size? Do they fit every conduit on the market? What happens when the knockout is larger or smaller than the conduit? This guide will tell you. Conduit Knockout Size – Why Does It Matter? 1″ conduit requires a 1.375″ knockout; 3/4″ conduit requires a 1.109″ knockout; 1/2″ conduit requires 0.875″ knockout

0 · make your own cnc mill

1 · make your own cnc machine

2 · do it yourself cnc machine

3 · diy woodworking cnc

4 · diy cnc machine for woodworking

5 · building your own cnc router

6 · building your own cnc machine

7 · build your own cnc mill

Wires, receptacles and switches need adequate space. Crowded boxes can damage wires, resulting in a fire or shock hazard. You can use the chart below to calculate the required box size. Add up the numbers for the correspond- ing components in the box to find how many cubic inches you’ll need.

Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

Before getting hands-on with your DIY wood CNC machine, you'll need to gather the necessary materials and tools. We'll provide you with a comprehensive checklist of everything you need, .Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, . Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it .

make your own cnc mill

Discover how easily you can build a powerful "Ultra-Precise" CNC Woodworking Machine --Hobby version/Desktop version/Professional wooden and/or metal base ve.Here are a few steps that will help you build your own CNC router and allow you to work on intricate woodworking projects: What specifications are you looking at? If the market for CNC machines are full of a wide range in size, you can .I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow .

build cnc machine kits

Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting journey of creating intricate designs and achieving precise cuts. This is your complete guide to DIY CNC. How to choose a machine type (diy cnc router?) and the resources you'll need to build it. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Before getting hands-on with your DIY wood CNC machine, you'll need to gather the necessary materials and tools. We'll provide you with a comprehensive checklist of everything you need, such as wood, electrical components, motors, bearings, threaded rods, and more.

make your own cnc machine

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.

Discover how easily you can build a powerful "Ultra-Precise" CNC Woodworking Machine --Hobby version/Desktop version/Professional wooden and/or metal base ve.Here are a few steps that will help you build your own CNC router and allow you to work on intricate woodworking projects: What specifications are you looking at? If the market for CNC machines are full of a wide range in size, you can choose to .

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting journey of creating intricate designs and achieving precise cuts.

This is your complete guide to DIY CNC. How to choose a machine type (diy cnc router?) and the resources you'll need to build it.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

Before getting hands-on with your DIY wood CNC machine, you'll need to gather the necessary materials and tools. We'll provide you with a comprehensive checklist of everything you need, such as wood, electrical components, motors, bearings, threaded rods, and more.

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.Discover how easily you can build a powerful "Ultra-Precise" CNC Woodworking Machine --Hobby version/Desktop version/Professional wooden and/or metal base ve.

budd electrical enclosures

Here are a few steps that will help you build your own CNC router and allow you to work on intricate woodworking projects: What specifications are you looking at? If the market for CNC machines are full of a wide range in size, you can choose to .

do it yourself cnc machine

build lower reciever with cnc machine

bug box electrical panel

A list of metal fabrication machines and equipment used to produce highly complex fabrications, how they work, and the importance of qualified operators.

diy wood cnc machine|building your own cnc machine