cnc machining component 7 Key Components of a CNC Machine. 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine. It reads the G-code (the programming language for CNC) . Discover our extensive range of affordable aftermarket CNC replacement parts, designed to keep your machines operating at peak performance. Our high-quality components ensure reliability and longevity, offering a cost-effective alternative to OEM parts.

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · main parts of cnc machine

3 · diagram of cnc lathe machine

4 · cnc machine tool components

5 · cnc machine parts diagram

6 · cnc machine components list

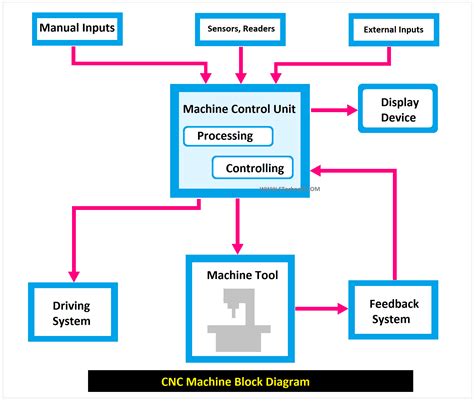

7 · block diagram of cnc machine

This versatile folding utility knife features a retractable, Fiskars CarbonMax blade that stays sharp up to 24 times longer than standard blades, saving you time .

7 Key Components of a CNC Machine. 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine. It reads the G-code (the programming language for CNC) .K+

5K+K+K+ This section aims to provide an overview of the various components found in CNC machines. While certain parts such as the control .

CNC machine tools can be classified into three grades based on the main technical parameters, functional indicators, and functional levels of their key components in the CNC system: low, medium, and high.

The CAM software is a crucial component of CNC machining, as it translates the design data into a language that the CNC machine can understand and autonomously execute. To achieve this, CAM programming employs different . Common Components of CNC Machine. Any CNC machine includes several individual components working together to execute the machining processes; mechanical hardware, electrical circuits, sensors, computer software, etc. Here are the most common components; Bed. A bed is a rigid and stable plane typically made with cast iron alloys.

An in-depth examination of the 9 integral parts of a CNC lathe machine, exploring their functionalities, significance in the machining process, and insights into their evolution over time. . The spindle, a vital component in .

CNC Machining Components for Space. Intrex Aerospace is an experienced manufacturer. We provide precision CNC machining components for space.We have an experienced staff and the right systems in place to deliver quality machined space components. Space and .

CNC machining is characterized by precise movements of the tools about the workpiece, which is defined by a computer-aided design and can allow small tolerances. . If you need to custom precision component for your product, TOPS is your first choice. Send us your detailed requirement and get an instant quote now. Services. CNC Machining; Die . The Numerical Control Unit (NCU) is the most crucial component of a CNC machine tool, and the functionality of the CNC machine tool depends on the quality of the NCU. It primarily consists of three parts: input, processing, and output of information. The program carrier transfers machining information to the CNC unit through the input device .

The machine control unit (MCU) is a crucial electronic hardware and software component of a CNC machine. Its role is to read the supplied G-code and translate it into instructions that the tool drivers can execute to perform the required machining operations.Your Reliable Partner in Machining. We specialize in Stainless Steel (Edelstahl) - Precision Machined Components & Special Turned Fasteners. Turning - Milling (Drehen - Fräsen) Turned Fasteners . Stainless Steel Bright Bars. CNC Turned Components. We strive for excellence in all we do. The result is a product that meets and exceeds our .

Kalman Manufacturing provides precision CNC machining, designing, prototyping & finishing of mechanical components in Silicon Valley, CA. Processing time is a critical component in CNC machining that significantly impacts the overall production cost. This encompasses all activities from the initial setup to the final handling of the machined parts. Setup Costs . Setting up a CNC machine is particularly labor-intensive and costly, involving the installation of appropriate tools .

COMPONENT CAPABILITIES. Miller CNC machines components to customer specifications. Our scope of work includes machining parts made from bar, plate, forgings and castings using 3 Axis, 4 Axis, and 5 Axis mills along with CNC lathes. We primarily machine Inconel™, titanium, stainless steel, and exotic alloys in production lot sizes of 50-1000 pieces and we support .Rely On One Of The Trusted Machined Component Manufacturers. We are one of the most efficient machined component manufacturers with adequate experience in producing different types of precision engineering equipment. Our experience in producing accurate components and the emphasis on delivering the best-quality machined parts makes us a leading supplier in this .CNC Machining Components is the automation of work process in manufacturing industries. Our company manufactures a unique range of CNC Machining Components which are made available in various specifications.

Machined Components. Machined Components is a China CNC precision machining manufacturer and Chinese CNC machining company with state-of-the-art CNC manufacturing factory based in China. We provide custom 3-axis to 5-axis CNC Machining Services, CNC Milling Services, CNC Turning Services, CNC Grinding Services, Wire EDM Machining and .

CNC machining components for Aerospace, Defense, and Space. If you’re in the market for comprehensive supply chain interactions for your defense, aerospace, or space projects, let the Intrex Aerospace team put its expertise to work. Our .Crucial Component Machining LLC SERVING THE CONCORD, NEW HAMPSHIRE AND BOSTON-NORTH AREA Precision CNC Milling, Turning & Screw Machining of Metals and Plastics With exceptional customer service, .

Runsom Precision offers a wide range of custom online CNC machining services, including 3, 4, and 5-axis CNC milling and CNC turning, grinding, EDM, laser cutting, and others.There are abundant CNC machining services from design, .In this article, we will introduce you to the features and benefits of our CNC machining components, and show you how they can add value to your business. Features of our CNC Machining Components: 1. High Precision . Our CNC machining components are made with the highest precision, ensuring that they meet the exact specifications of your project.

CNC machining is a subtractive manufacturing technology that automatically removes material from raw stock based on a set of computer-generated instructions. . Machining component mounting holes into printed circuit boards and machining aluminum or copper heat sink for heat-generating electrical components are some examples of the use of CNC .CNC Turning (Lathe Machining): Generally, a Lathe machine is used for machining cylindrical components, also known as turning operation. The major difference between Lathe and Milling machine is, in Lathe machine work-piece is held in a rotating chuck and cutting tool is fixed to the tool post of the machine carriage. The Machine Body is the central component of the CNC Machine Tool, comprising of the basic large parts (such as the bed and the base) and various moving parts (such as the workbench, bed saddle, and spindle). It is a mechanical component that performs various cutting operations and is an improvement over conventional machine tools.

In the modern environment characterized by rather rapid development of technologies, the needs for custom, high value added parts remain high. Starting from component manufacturing and highly specialized injection molding, through the most sophisticated CNC machining and metal 3D printing companies such as Norck are changing the face of .eMachineShop manufactures low-cost prototype and production runs of custom parts. Get a fast quote or design and order your parts with our free CAD software. We offer CNC Milling and Turning, Sheet Metal Fabrication, Injection Molding, and dozens of materials. Online Ordering. Free Shipping. Quality Guaranteed.We produce CNC-machined precision components from a variety of materials – everything from copper and plastics to demanding alloys. We currently manufacture, for example, lock, welding, hydraulic, and instrument components and produce special parts for different industries. We also offer different surface treatments through our supplier network.

Metals. Different metals respond uniquely to CNC machining processes, each presenting its specific challenges and common defects. Aluminum. Burrs: Due to aluminum’s softness, it often forms burrs, which are small, raised edges or pieces of material that remain attached to a workpiece after a modification process.; Adhesion to Cutting Tools: Aluminum .After CNC machining, we may apply anodization to the component, a treatment commonly used for aluminum machined parts. This process creates a durable and corrosion-resistant finish that also enhances the wear resistance of the component.It is also suitable for vibrating parts and moving components. This CNC machining surface roughness adds 5% to the baseline production cost, as it requires close control and meticulous machining to produce. The part in the image below has a 0.8 µm Ra surface roughness. 0.8 µm Ra CNC machining surface roughness (CNC turning - Aluminium)

schematic diagram of cnc machine

parts made by cnc machine

New Lon0167 170mmx140mmx95mm 1 Featured Inlet to 2 reliable efficacy Outlet Waterproof Junction Box w Connector Gland(id:278 4d ad 713) - Amazon.com

cnc machining component|main parts of cnc machine