22 possible causes of weld metal porosity the fabricatorthe fabricator Weld porosity is a dangerous weld defect that has myriad causes. Rob Koltz and Nino Mascalco analyze a reader's situation and help him nail . The Valley of Steel Boxes, The Valley of Steel Boxes . The Valley of Steel Boxes. Stack Size 9. Wiki wiki. Buy. 1.0. The Valley of Steel Boxes. for. 46.6. Chaos Orbs. Trade . The Valley of .

0 · what causes pinholes in welding

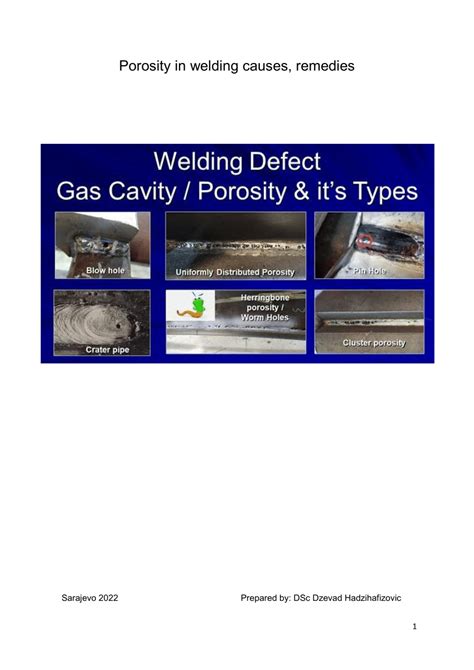

1 · welding porosity causes and remedies

2 · weld porosity troubleshooting

3 · types of porosity in welding

4 · improper gun technique cause porosity

5 · how to correct porosity welding

6 · how is piping porosity formed

7 · different types of porosity welding

Autodesk Inventor’s part (.ipt) and assembly (.iam) file formats are commonly used in CNC machining for their strong parametric design capabilities. These files store detailed 3D part and assembly information, allowing manufacturers to create highly accurate parts.

Simply put, porosity occurs when nitrogen, oxygen, or hydrogen becomes trapped inside the molten weld pool as it solidifies. Those gases either leave a subsurface void or they .

distribution processing center po box 34740 north kansas city mo

Weld porosity is a dangerous weld defect that has myriad causes. Rob Koltz and Nino Mascalco analyze a reader's situation and help him nail .One of the primary causes of porosity is the presence of contaminants such as moisture, oil, grease, rust, or paint on the base metal or filler material. When these contaminants are exposed to the high temperatures of welding, they can . Most welding processes can experience porosity, but it is prevalent in TIG welding, MIG welding, and flux-cored arc welding. The susceptibility depends on factors like shielding gas usage, technique, and .

what causes pinholes in welding

Welding porosity is the presence of small voids or pockets in the weld metal, caused by gas bubbles trapped during the solidification process. Understanding causes porosity in welding is essential to ensuring high-quality, . Understanding the causes of welding porosity is the first step toward prevention. Common causes include: Contaminated Base Material: Dirt, oil, and other contaminants on the .

Understanding the causes of welding porosity is the first step toward prevention. Common causes include: Contaminated Base Material: Dirt, oil, and other contaminants on the base material can lead to porosity. . In fact, most causes of weld defects can be traced back to two general areas: first, a combination of poor instruction and workmanship; second, poor weld design and/or material choice. A welder may produce poor work for . Welding porosity is a common defect encountered during the welding process, characterized by gas holes formed in the weld metal. These pores not only compromise the . Porosity in welding is a common defect that is fairly easy to fix. What issues contribute to weld porosity? Read our checklist to learn what the problem may be.

welding porosity causes and remedies

weld porosity troubleshooting

Simply put, porosity occurs when nitrogen, oxygen, or hydrogen becomes trapped inside the molten weld pool as it solidifies. Those gases either leave a subsurface void or they leave a pore that is visible at the surface. 1. Porosity caused by nitrogen or oxygen. This type of porosity mainly is due to inadequate shielding gas coverage.

Weld porosity is a dangerous weld defect that has myriad causes. Rob Koltz and Nino Mascalco analyze a reader's situation and help him nail down what's causing the porosity in his pipe fabrications.

One of the primary causes of porosity is the presence of contaminants such as moisture, oil, grease, rust, or paint on the base metal or filler material. When these contaminants are exposed to the high temperatures of welding, they can release gases that create voids.

Most welding processes can experience porosity, but it is prevalent in TIG welding, MIG welding, and flux-cored arc welding. The susceptibility depends on factors like shielding gas usage, technique, and material preparation. Welding porosity is the presence of small voids or pockets in the weld metal, caused by gas bubbles trapped during the solidification process. Understanding causes porosity in welding is essential to ensuring high-quality, reliable welds that meet industry standards. Understanding the causes of welding porosity is the first step toward prevention. Common causes include: Contaminated Base Material: Dirt, oil, and other contaminants on the base material can cause porosity. Improper Shielding Gas: Inadequate or improper shielding gas can lead to gas absorption in the weld pool. Understanding the causes of welding porosity is the first step toward prevention. Common causes include: Contaminated Base Material: Dirt, oil, and other contaminants on the base material can lead to porosity. Improper Shielding Gas: Inadequate or improper shielding gas can result in gas absorption in the weld pool.

In fact, most causes of weld defects can be traced back to two general areas: first, a combination of poor instruction and workmanship; second, poor weld design and/or material choice. A welder may produce poor work for many reasons, including poor instruction. Welding porosity is a common defect encountered during the welding process, characterized by gas holes formed in the weld metal. These pores not only compromise the strength and quality of the weld but can also lead to leaks or fractures in welded structures.

Porosity in welding is a common defect that is fairly easy to fix. What issues contribute to weld porosity? Read our checklist to learn what the problem may be. Simply put, porosity occurs when nitrogen, oxygen, or hydrogen becomes trapped inside the molten weld pool as it solidifies. Those gases either leave a subsurface void or they leave a pore that is visible at the surface. 1. Porosity caused by nitrogen or oxygen. This type of porosity mainly is due to inadequate shielding gas coverage.

Weld porosity is a dangerous weld defect that has myriad causes. Rob Koltz and Nino Mascalco analyze a reader's situation and help him nail down what's causing the porosity in his pipe fabrications.One of the primary causes of porosity is the presence of contaminants such as moisture, oil, grease, rust, or paint on the base metal or filler material. When these contaminants are exposed to the high temperatures of welding, they can release gases that create voids. Most welding processes can experience porosity, but it is prevalent in TIG welding, MIG welding, and flux-cored arc welding. The susceptibility depends on factors like shielding gas usage, technique, and material preparation.

Welding porosity is the presence of small voids or pockets in the weld metal, caused by gas bubbles trapped during the solidification process. Understanding causes porosity in welding is essential to ensuring high-quality, reliable welds that meet industry standards.

types of porosity in welding

Understanding the causes of welding porosity is the first step toward prevention. Common causes include: Contaminated Base Material: Dirt, oil, and other contaminants on the base material can cause porosity. Improper Shielding Gas: Inadequate or improper shielding gas can lead to gas absorption in the weld pool. Understanding the causes of welding porosity is the first step toward prevention. Common causes include: Contaminated Base Material: Dirt, oil, and other contaminants on the base material can lead to porosity. Improper Shielding Gas: Inadequate or improper shielding gas can result in gas absorption in the weld pool. In fact, most causes of weld defects can be traced back to two general areas: first, a combination of poor instruction and workmanship; second, poor weld design and/or material choice. A welder may produce poor work for many reasons, including poor instruction.

improper gun technique cause porosity

Looking to find the most effective fabric glue for bonding plastic and metal materials? This in-depth analysis will guide you through the top options, comparing their adhesion strength, drying time, and suitability for different materials.

22 possible causes of weld metal porosity the fabricatorthe fabricator|different types of porosity welding