diy cnc machine design Design Your Machine: Start with a clear design. There are various online platforms like Fusion 360 or TinkerCAD that you can use to design or modify existing designs. Frame: Usually made from materials like aluminum, .

Specializing in hard-to-produce, tight tolerance, appearance focused custom metal stampings, sheet metal fabrications, and assemblies. Our integrated value-added manufacturing services result in faster production turnaround, reduce your project management time, and provide cost saving opportunities.

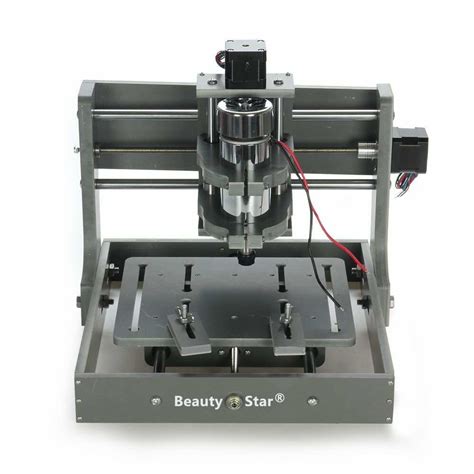

0 · hobby cnc machine complete kit

1 · do it yourself cnc machine

2 · diy cnc machine for woodworking

3 · cnc machine for home hobbyist

4 · building your own cnc machine

5 · build your own cnc mill

6 · best cnc router for beginners

7 · best cnc machine for woodworking

Get fast turnaround on quotes for custom mechanical components, including prototyping and production parts. WM Berg is US-based, allowing us to respond to requests for nonstandard and special parts quickly. Our world-class manufacturing facility includes a CNC/DNC machine shop, R&D lab and stringent quality assurance.

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this .Here you will find the design process I went through for my CNC router. What type of .I decided to put my engineering background to the test, and build my own CNC .

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of . Design Your Machine: Start with a clear design. There are various online platforms like Fusion 360 or TinkerCAD that you can use to design or modify existing designs. Frame: Usually made from materials like aluminum, .

This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled. It .

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY .Learn how to build a DIY CNC router step by step, from preparing the workspace to final assembly and testing. Get valuable tips along the way. Before starting, I ensured my workspace was spacious enough to accommodate a 5-foot by 5 . Ideally, the Do it yourself (DIY) CNC milling machine you build should be able to carve out objects in different dimensions from a solid block of material. It should also provide cuts that are more accurate and elaborate. .

Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, .This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of CNC routers: the moving table design and the moving gantry design. Moving table style designs are often used for smaller size CNC routers.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine. Design Your Machine: Start with a clear design. There are various online platforms like Fusion 360 or TinkerCAD that you can use to design or modify existing designs. Frame: Usually made from materials like aluminum, steel, or even wood. It’s the skeleton of your machine and needs to be sturdy.

This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled. It also includes instructions of how all the necessary open-source softwares are installed. Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine. What is a CNC Machine?

Learn how to build a DIY CNC router step by step, from preparing the workspace to final assembly and testing. Get valuable tips along the way. Before starting, I ensured my workspace was spacious enough to accommodate a 5-foot by 5-foot CNC router. Ideally, the Do it yourself (DIY) CNC milling machine you build should be able to carve out objects in different dimensions from a solid block of material. It should also provide cuts that are more accurate and elaborate. Read through this write-up and learn how to build a DIY CNC machine by yourself from scratch. What's On This Page?Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. Fastest path to ownership.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Here you will find the design process I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of CNC routers: the moving table design and the moving gantry design. Moving table style designs are often used for smaller size CNC routers.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.

Design Your Machine: Start with a clear design. There are various online platforms like Fusion 360 or TinkerCAD that you can use to design or modify existing designs. Frame: Usually made from materials like aluminum, steel, or even wood. It’s the skeleton of your machine and needs to be sturdy.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled. It also includes instructions of how all the necessary open-source softwares are installed. Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine. What is a CNC Machine?

Learn how to build a DIY CNC router step by step, from preparing the workspace to final assembly and testing. Get valuable tips along the way. Before starting, I ensured my workspace was spacious enough to accommodate a 5-foot by 5-foot CNC router. Ideally, the Do it yourself (DIY) CNC milling machine you build should be able to carve out objects in different dimensions from a solid block of material. It should also provide cuts that are more accurate and elaborate. Read through this write-up and learn how to build a DIY CNC machine by yourself from scratch. What's On This Page?

hobby cnc machine complete kit

do it yourself cnc machine

diy cnc machine for woodworking

Get precision CNC turned parts for prototyping and production with RALLY, delivering top-quality metal and plastic components as quickly as 2-3 day. Start with an instant online quote. At Rally, we understand that it is essential to meet the technical specifications of customers’ orders in an accurate and timely manner.

diy cnc machine design|cnc machine for home hobbyist