how to write code for cnc machine The third video in my new series 'Let's write G-Code' G-Code tutorial.This is the 3rd part of a 6 part series on how we can program a CNC Lathe to produce a .

A banged-up Vintage Lunch Box costs about $100, while the ones in stellar condition goes for over $1,000. As you run to your bedroom searching for a possible priceless vintage metal lunch box, use this list to separate the valuables from the worthless. 7. Howdy Doody. 6. Hopalong Cassidy. 5. Knights in Amour. 4. Mickey Mouse & Friends. 3. Superman.

0 · understanding g code programming

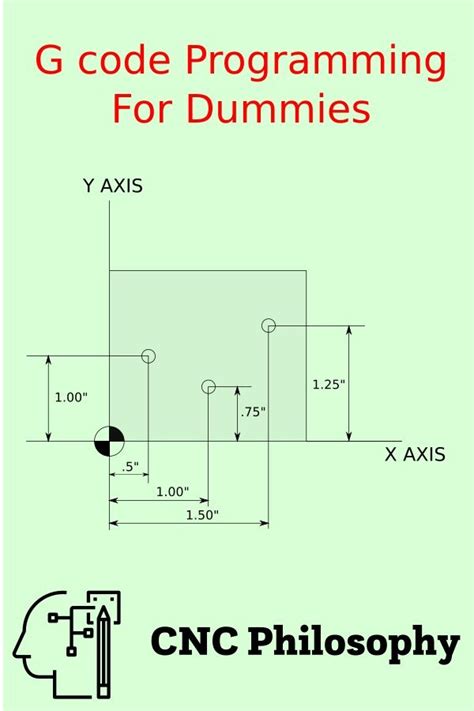

1 · g code programming for dummies

2 · g code for beginners

3 · example of cnc programming

4 · cnc router programming for dummies

5 · cnc programming for dummies

6 · cnc g code for beginners

7 · basic cnc programming codes

In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle .

Basic cnc programs are not too difficult to do. A hobbyist Cnc operator should not have any difficulty in learning how to write simple G code programs. I say “basic” because you will need to decide when it will be easier or quicker to create a Cnc Projectin a cad/cam program than it will be to write your own cnc . See more

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or . Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated .I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines

CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write . The third video in my new series 'Let's write G-Code' G-Code tutorial.This is the 3rd part of a 6 part series on how we can program a CNC Lathe to produce a . In this tutorial I`ll show you how to create gcode for CNC machine consisting 2 stepper for X and Y axis and a servo for Z axis. Follow these steps to create. G-code is everywhere, from 3D printing to CNC. Easily learn the basics of CNC programming with this G-code tutorial in six simple steps.

Hi dear tim. my name is afshin and i recently made a cnc just for fun.i used arduino uno and cnc shield plus A4988 drivers.and for stepper motors i using nema 23.after plenty search i fined your article and i did everything you said but when i ran the circle.nc code my stepper . The third type of end user includes CNC programmers and machine operators who have learned to go into the post and change lines of code to change its functionality. For example, most machinists who need to make a minor variation on a part that has already been programmed will simply modify the G and M code at the machine. In this video I am going to review my brand new CNC Machine 3018, I will also tell you how to generate g-codes for cnc milling. I have purchased this machine.

For the ultimate tinkerer, developer or the real DIY PyCNC allows almost someone to take an existing CNC machine connect it to a Raspberry Pi and with a bit of wiring use Python to write G Code with Python. With PyCNC your code controls the motors using a Linux system which normally would not be feasible due to Linux not having real-time GPIO . The fifth video in my new series 'Let's write G-Code' G-Code tutorial.This is the fifth part of a 6 part series on how we can program a CNC Lathe to produce . SOFTWARE LINKS 1. GRBL : https://github.com/grbl/grbl2. USGB : https://winder.github.io/ugs_website/3. INKSCAPE : https://inksc. I'm looking for a simple facing program I can type into a Haas VF3. I just got the machine up and running but I don't have my computer and software to program parts with yet. I'm learning G-code but am extremely new at it. I just want to try out the machine and see if everything works ok after trucking it from Dallas to Seattle in -0* weather..

This video demonstrates the essential G codes that begin most programs and what they mean

Software for CNC Programming. You don’t have to learn G-code to create CNC programs. There’s software that will write the code for you, but it can be expensive. If you learn a few G-code commands, you’ll be able write your own programs without spending a dime. You can create a CNC program in any text editing application. Writing G code for a CNC lathe machine is an essential skill for any operator or programmer. By understanding the basics of G code and following the steps outlined in this article, you can create accurate and efficient programs that maximize the machine’s capabilities. Whether you choose to write G code manually or use CAM software, the key .WHY LEARN G-CODE? Every CNC machinist should know g-code. If you're interested in CNC and machining, you should too. We recently did a survey to assess the g-code skills of our readership. You should not be suprised to learn that many are quite proficient with G-Code: We were impressed at how many readers can write g-code programs from scratch. In

understanding g code programming

Code Quality: ChatGpt messed up a lot.Using G81 and G83 without changing tools and canceling cycles is not possible in G-Code language. Moving to the Z0. with rapid movement would be the last thing a machinist can do with a CNC . Since its debut, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? . machine operator, this webinar will offer valuable insights into optimizing CNC .

Answer to write letter "C", "M" and "L" in G-code, cnc machine. N10 (i) N20 (i) N30 GO Z2 N40 GO X129.386 Y100 N50 G1 Z-1 F100 N60 G1 X168.86 Y97.753 F200 NZO G1 X184.211 Y92.978 N80 G1 X168.86 Y87.921 N90 G1 X129.386 Y85.674 N100 G1 X89.912 Y87.921 N110 G1 X72.368 Y92.978 N120 G1 X89.912 Y97.753 N130 G1 X129.386 Y100 N140 GO Z2 N150 GO .

There are many cool commands, including canned cycles. Im too lazy to explain all of them because there are more than 180 G codes and machine depending there are 100 or more M codes. Look up more for yourself or get a machine manual for your machine. With Cnc machines the options and opportunities are endless!If you are a proud owner of a desktop CNC Router or are looking to improve your knowledge in a professional industry. you need to have a complete understanding of how to program FANUC G-Code. This course will teach you how to program CNC parts using G-Code, the language of CNC Machines. All Cycles Explained. G81 drilling cycle. G82 Counter boringHow to mill a full circle, no problem below is the cnc program example G-code which shows how to program a full circle on a cnc milling machine. Often cnc machinists has to complete such components which require a full circle machining sometimes inside full circle sometimes you have to program an outside full circle.

G-code: The most common programming language used for CNC machines. It tells the machine how to move, at what speed, and in what direction. G-code controls the tool’s movement along the X, Y, and Z axes, as well as additional parameters like spindle speed, coolant flow, and more. M-code: Another set of commands used in CNC programming, often . These individuals manually wrote machine code and fed it into the machine. As part of their code-writing responsibilities, they planned and documented the sequential processing steps the machine should follow. These sequences included: Tool movement, e.g., position, direction, and speed; Spindle rotation speed and direction #cncturningprogram #basiccncprogramming #cncprogramforbeginners #cnc #excellentideasineducation #cnclathe #cncprogramming #mechanicalengineering #mechanical .

In this video you will learn how to setup cnc machine using solidworks. I will describe some basic functions of solidworks HSM express to make gcode for cnc . Part of my job consists for writing programs for trimming parts on CNC machines. In this video I write a basic program that will flush trim a part using a 5. When it comes to the manufacturing CNC job shops or modern machine shops, there is a lot to discuss on the subject of CAD-CAM for CNC Metalworking and G-Code Programming and Machining. CAD-CAM providers look at how a shop handles the workflow from when a job comes in to how the job is finished on the CNC machines.

g code programming for dummies

metal belt buckle fabrication

metal box 4 men with beards

g code for beginners

CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

how to write code for cnc machine|cnc programming for dummies