parts of a cnc mill Precision machining, particularly CNC (computer numerical control) machining, is vitally important in today’s economy, specifically for industries needing parts with unparalleled accuracy and complexity.

Online weight calculator for alloy metals including aluminium and stainless steel. Calculate the weight of various forms including box sections, sheets, bars and pipes.

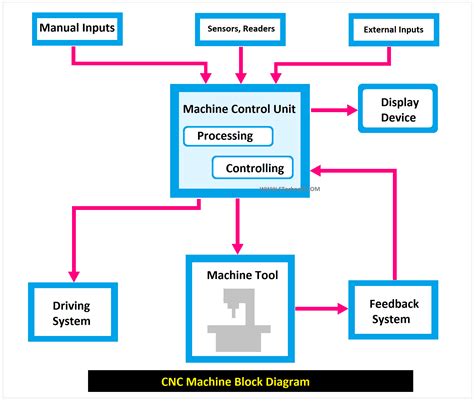

0 · schematic diagram of cnc machine

1 · milling machine parts diagram

2 · homemade cnc parts

3 · cnc milling machine parts names

4 · cnc mill parts diagram

5 · cnc mill diagram

6 · cnc machine parts list pdf

7 · cnc horizontal milling for dummies

WAGO's wire splicing connectors are the ideal product for electrical installation. Fast and easy to use, they take up minimal space, and provide permanent, secure connections whether in a junction or distribution box.

Although the milling operations on the two styles of milling machines might vary, the milling machine parts that make them up have much in common. We’ve created a list of the essential parts of a CNC milling machine .

Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of . CNC milling is a subtractive manufacturing process where material is removed from a solid block to create parts. That being said, there are basic components in every CNC mill that allow it to function as intended. I’ve .

CNC milling is a reliable and standard method for fabricating parts in mass volume, with each part having the same level of quality and finish. Moreover, CNC mills, especially 3-axis milling machines, are often easy to . The main parts include the base, column, knee, saddle, table, spindle, and cutting tools. The base provides a sturdy foundation for the entire machine, while the column supports the knee and houses the drive .

Precision machining, particularly CNC (computer numerical control) machining, is vitally important in today’s economy, specifically for industries needing parts with unparalleled accuracy and complexity.1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine. It reads the G-code (the programming language for CNC) and converts it into electrical signals .K+5K+

K+ CNC milling machines are equipped with several essential parts that work in unity to facilitate the machining process. These machines use computer numerical control (CNC) and automated features to control the . CNC milling is an automated, subtractive manufacturing technology designed to remove material in a controlled, pre-programmed manner to produce parts. Almost any material can be processed using CNC milling, .

The CNC spindle is the machine’s part that holds and rotates all cutting tools. Its main task is to provide the necessary speed and torque for the cutting operation. CNC mills and CNC lathes use different spindles depending .

For instance, a CNC machine provides high-quality finishing procedures, including anodizing, polishing, heat treating, plating, powder coating, and more, for the majority of CNC-machined parts. Limitations of CNC . Spindles in milling machines may have different types of tool holders, such as collets, end mill holders, or drill chucks. These tool holders securely grip the cutting tools, ensuring stability and precision during . have the mill drill (or for bonus points, interpolate the holes with an end mill) a square pattern of 4 holes equal distance apart in x and y. Run 2 parts. Then see if they fit together with slip fit dowel pins, and again after turning one 90 and/or 180 degree's from how they sat in . Most 3D Printed Parts Kits consist of mostly ABS & ASA in a variety of colors, I'm offering parts made of alternate and/or stronger materials which also include installed threaded inserts so you can skip all of the time and work, not only 3D Printing all of the parts, which is a bit of a chore and takes quite a bit of filament, but also the time and effort of installing all of the .

Milling machines with CNC are an integral part of the manufacturing industry with a unique design that sets them apart from their vertical counterparts mill machine without CNC. These CNC machines feature a horizontally oriented spindle that holds cutting tools, allowing chips to fall away more quickly and making these milling machines .In conclusion, designing parts for CNC milling necessitates engineering expertise and a practical understanding of the manufacturing process. By optimizing the design for CNC milling, parts can be produced more efficiently and accurately, ultimately leading to higher-quality products and improved production efficiency.In a CNC mill, the pallet moves horizontally in the z-direction, and the cutting tool horizontally and vertically in x- and y-directions. Footswitch or Pedal: CNC operators use foot pedals to open and close the chuck, allowing for easy loading and unloading of parts. Additional CNC Machine Info a Beginner Should Know

cnc machining morgan hill

Milling is suitable for many different features, including threading, chamfering, slotting, etc. This makes it possible to produce complex designs using a variety of different milling operations: Surface milling, face milling, angular milling, form milling, profile milling, gear milling, etc. Discover the parts of a CNC milling machine. What . Choosing the right material is crucial for the functionality and durability of your CNC milling parts. Advantages of CNC Milling Parts. Precision: CNC machines offer high accuracy, ensuring parts meet exact specifications. Repeatability: Ideal for producing multiple identical parts. Versatility: Capable of creating complex shapes and intricate .CNC Mill (798) CNC Lathe (498) Vertical Machining Center (646) Horizontal Machining Center (139) Boring Mill (13) Router (106) EDM (21) Manual and Other Machining (19) Fabrication (143) . Understanding the parts of a CNC machine and their functions, as illustrated in the CNC block diagram, is fundamental for anyone working with or learning . At times, some of these parts will have reasonably tight tolerances for parallelism and/or flatness, for example +/- .002 on dimension, or .0008 total parallelism. . I'll admit - I am rather inexperienced with CNC milling. I've had to take on the role of programmer due to our previous man leaving, and I really want to try to solve this problem.

CNC milling is ideal for creating custom, one-of-a-kind parts without incurring the significant setup costs associated with other manufacturing processes. This makes it particularly valuable for bespoke projects or industries where customization is critical, such as aerospace or medical device manufacturing, where tailored components are often .A CNC milling machine is a computer-controlled automation device that shapes materials into precise parts using cutting tools and controlled movements. What propels these machines into action? How do these devices meet project demands for high-precision, complex components? To unravel these questions, let's delve into the core components that power the precision of CNC .Figure 4 depicts an example of a part mounted on the bed of a CNC mill. In the case of a CNC lathe, the tool turret and the tailstock are secured to the bed, while the chuck holds the raw material. 9. The Tailstock. The tailstock is an .

Their CNC Swiss and CNC turning machines can handle parts ranging from 0.145″ to 3.25″ in diameter, and they also have the ability to mill features onto turned parts. Whether it’s for large, square, or flat parts, or . CNC machines use a variety of cutting tools, including drills, end mills, and lathes, to produce parts with complex geometries and tight tolerances. These machines are highly versatile and can be used to produce parts from a . CNC mills are often classified by the number of axes on which they can operate or spindle directions. 1. Vertical Mill. A vertical mill or milling machine’s spindle axis is vertically oriented, which means the cutting tools on the spindle will shape the materials vertically, and the cutters move while the workpiece remains stationary, the machines can cut into the part easily.

I am new to this forum. We are a small family business manufacturing medical devices for a big company. We do the machining on CNC Mills and Lathes and we also have some outside processes (i.e. anodizing, passivating, etc.) They require a PFMEA from us. Would anyone have a example to get.Introduction to CNC Milling Machine Parts. With the advancement of technology, it is easier than ever to make the parts you need. Computer numerical control (CNC) has changed the landscape of manufacturing. It involves using pre-programmed computer software to control the movement and precision of machine tools. The parts of the CNC machines are costly. Maintenance costs are significantly higher in the case of CNC. . and demands, the demand for CNC usage has increased to a greater extent. The machine tools that come with the CNC are late, mills shaper welding, etc. The industries that are using CNC machines are the automotive industry, metal removal .The advantages of CNC milling are huge: Precision: We’re talking accuracy down to fractions of a millimeter. Consistency: Every part is identical, which is crucial for things like aerospace components. Complexity: CNC mills can create shapes .

Basics of the CNC Mill 212 Learn with flashcards, games, and more — for free. . My PowerPlant Oral Study Guide Part 2. 86 terms. Argie_Jaramillo. Preview. heat transfer. 10 terms. jul903431. Preview. THV3 nights. 10 terms. Jim_Magee2. Preview. ASTB Nautical/Aviation Terms. 70 terms. Colby_650. Preview. MP Quiz 4. 25 terms. kenzieday341. The table is another crucial component of a CNC milling machine, as it determines the size and shape of the parts that can be produced. A larger table will allow the machine to cut larger parts, while a smaller table may be more suitable for smaller parts or limited workspace. Haas is a huge name in the CNC industry and provides exceptionally high quality, professional standard machines around the world. It creates a huge variety of different milling machines, but the Modular Mini Mill is the cheapest professional CNC mill to date, though it’s still not cheap!. This compact mill boasts an impressive 40-taper performance despite being much .

CNC milling is a highly precise and efficient manufacturing process that produces complex and accurate parts. However, despite its precision, CNC milling parts can sometimes experience deformation, resulting in defective parts that do not meet the required specifications. This deformation can occur due to various factors that affect the machining process, such as . A CNC milling machine parts Bed. The hardened part of the machine that carries all the load. All the other components are mounted over the bed. It is made of hard metal, and as the tool turret travels over this part. Headstock: It is the main part of the CNC machine. The workpiece is fixed on the headstock to carry out the desired operation.

schematic diagram of cnc machine

This article covers everything you need to know about welding thin sheet metal: from tips for beginners to advanced welding techniques that experienced professionals use under difficult circumstances.

parts of a cnc mill|cnc mill diagram