18 gauge vs 22 gauge sheet metal When working with sheet metal, the term “gauge” is often used. Gauge are used to . SWITCH BOX definition: a box , usually of metal, containing one or more electric switches | Meaning, pronunciation, translations and examples in American EnglishThis is essentially a new Mutec Distributor WS — a world clock distribution amplifier and signal converter. It's the smart and bulletproof way to split and mult your word clock signals. Much advised over merely running t-connectors.

0 · thickness of stainless steel gauge

1 · thickness of sheet metal gauge

2 · thickness of 18 gauge steel

3 · stainless steel gauge size chart

4 · sheet metal gauge size chart

5 · metal gauge thickness chart

6 · 12 gauge steel thickness chart

7 · 12 gauge sheet metal thickness

Work holding devices in CNC milling machines are crucial for achieving precise and efficient machining operations. Choosing the right work holding device depends on the size, shape, and material of the workpiece, as well as the desired machining operations.Workholding devices are essential tools used in CNC machining and other manufacturing processes to hold, clamp, or fixture a workpiece .

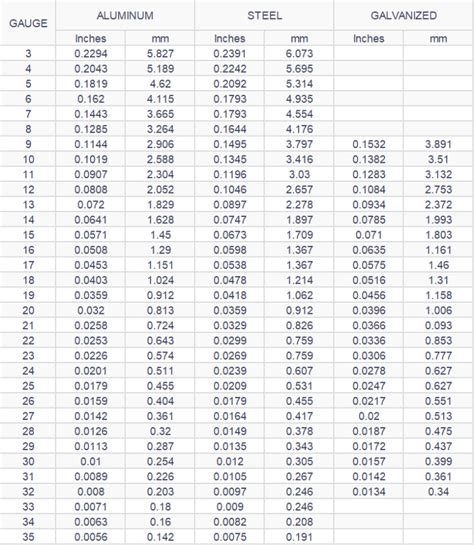

Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material.Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . When working with sheet metal, the term “gauge” is often used. Gauge are used to . For example, while 18-gauge steel might be suitable for a particular application due to its specific thickness and properties, 14-gauge steel could be more appropriate for projects requiring a thicker, more robust material. It's also .

A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for . The standard or metric equivalent of a gauge value depends on the metal. For example, 18-gauge sheet metal would be 0.040 inches thick if made from aluminum and 0.048 .

To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar .

The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard . Gauge charts can be used to measure the thickness of sheet metal regardless of the material it’s made from. They’re precise and indicate the standard and metric units of measurement. It may be easier for you to . Contrary to intuitive logic, a higher gauge number corresponds to thinner metal, while a lower gauge number indicates thicker metal. For instance, 18-gauge steel is thicker .Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material.

When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. For example, while 18-gauge steel might be suitable for a particular application due to its specific thickness and properties, 14-gauge steel could be more appropriate for projects requiring a thicker, more robust material. It's also worth noting the . Which is thicker 18 or 20-gauge sheet metal? 18 gauge metal is thicker. This ties back to the wire making origins of the gauge measurement system, as the number corresponds to the number of times the wire size was reduced, so reducing the wire size 20 times results in a smaller diameter than 18 times. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for accurate material selection and processing.

The standard or metric equivalent of a gauge value depends on the metal. For example, 18-gauge sheet metal would be 0.040 inches thick if made from aluminum and 0.048 inches thick if made from stainless steel. That’s why it is important to ensure you use the right conversion chart for the given piece of sheet metal.

To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar measurements—0.0478 inches or 1.214 millimeters for steel, for example.The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number . Gauge charts can be used to measure the thickness of sheet metal regardless of the material it’s made from. They’re precise and indicate the standard and metric units of measurement. It may be easier for you to understand how they work if we described them as sheet metal gauge conversion charts. Contrary to intuitive logic, a higher gauge number corresponds to thinner metal, while a lower gauge number indicates thicker metal. For instance, 18-gauge steel is thicker than 20-gauge steel. How are Sheet Metal Gauges Used? Sheet metal gauges are used to measure the thickness of metal sheets.

Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material.When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. For example, while 18-gauge steel might be suitable for a particular application due to its specific thickness and properties, 14-gauge steel could be more appropriate for projects requiring a thicker, more robust material. It's also worth noting the . Which is thicker 18 or 20-gauge sheet metal? 18 gauge metal is thicker. This ties back to the wire making origins of the gauge measurement system, as the number corresponds to the number of times the wire size was reduced, so reducing the wire size 20 times results in a smaller diameter than 18 times.

A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for accurate material selection and processing. The standard or metric equivalent of a gauge value depends on the metal. For example, 18-gauge sheet metal would be 0.040 inches thick if made from aluminum and 0.048 inches thick if made from stainless steel. That’s why it is important to ensure you use the right conversion chart for the given piece of sheet metal.

To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar measurements—0.0478 inches or 1.214 millimeters for steel, for example.

The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number .

Gauge charts can be used to measure the thickness of sheet metal regardless of the material it’s made from. They’re precise and indicate the standard and metric units of measurement. It may be easier for you to understand how they work if we described them as sheet metal gauge conversion charts.

how to connect electrical junction box

thickness of stainless steel gauge

thickness of sheet metal gauge

WoodLink manufactures and markets recycled plastic GOING GREEN® bird feeders and birdhouses, as well as a traditional line of cedar bird feeders, birdhouses and bird feeder accessories.

18 gauge vs 22 gauge sheet metal|thickness of stainless steel gauge