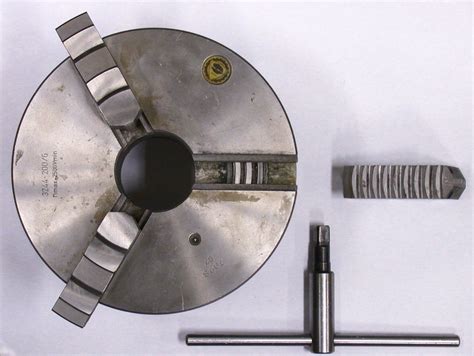

chucks for cnc machines A CNC chuck is a specialized clamp used in machining to hold a workpiece firmly on a machine tool, particularly a lathe machine. Its job is to secure the workpiece and ensure it can be accurately machined without .

Both welding before and after galvanizing are compatible with the objective of providing superior corrosion protection. Many commonly practiced welding and cutting techniques can be used on galvanized steel (see American Welding Societys (AWS) specification D .

0 · what is solid chuck

1 · what is a chuck engineering

2 · types of collet chucks

3 · strong lathe chucks

4 · replacement chucks for cnc machines

5 · power chucks for cnc lathes

6 · kitagawa chuck catalogue

7 · chuck jaws for kitagawa

Automating your woodworking using a Legacy CNC will revolutionize the efficiency, precision, and speed of your production. Legacy’s CNC systems automate more woodworking disciplines than any other CNC leading to increased productivity and .

Royal CNC Collet Chucks are proudly made in USA and are the preferred choice of all major machine tool builders. Every Royal CNC Collet Chuck includes a custom-machined drawtube connector for hassle-free installation, and with .A CNC chuck is a type of chuck specifically designed for use with Computer Numerical Control (CNC) machines. It is a clamping device that holds a workpiece securely in place during machining or cutting operations performed .Choose from our selection of CNC chucks, including machine tool holding, lathe chucks, and more. In stock and ready to ship.National Machine Products has partnered with TDG Clamping Solutions to provide a range of large diameter chucks that help optimize CNC machining production. TDG is a leading provider of innovative clamping solutions that .

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production. High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the . A CNC chuck is a specialized clamp used in machining to hold a workpiece firmly on a machine tool, particularly a lathe machine. Its job is to secure the workpiece and ensure it can be accurately machined without .

Techniks Collet Chucks are designed to deliver excellent performance in a wide range of machining applications including milling, drilling, and tapping. Our exclusive PowerCOAT nuts come standard on all ER and TG Collet Chuck .Super-High Precision Drill Chuck with Integrated Shank & Hexagonal Key Lock. Permits clockwise and counterclockwise turning. Significantly shorter than two-piece chuck and arbor. A single taper connection to the machine without .

what is solid chuck

Choose from our selection of keyless drill chucks, keyed drill chucks, drill chuck arbors, and more. In stock and ready to ship.GTS is an exclusive USA supplier of Autogrip power chucks, rotary cylinders, and accessories for CNC machining. We offer an entire line of Autogrip power chucks including 1,2,3 & 4 jaw power chucks, large thru-hole, heavy-duty power .Choose from our selection of CNC chucks, including machine tool holding, lathe chucks, and more. In stock and ready to ship.

Royal CNC Collet Chucks are proudly made in USA and are the preferred choice of all major machine tool builders. Every Royal CNC Collet Chuck includes a custom-machined drawtube connector for hassle-free installation, and with hundreds of chucks, collets, and accessories always in stock, virtually all Royal CNC Collet Chucks ship the same day .

A CNC chuck is a type of chuck specifically designed for use with Computer Numerical Control (CNC) machines. It is a clamping device that holds a workpiece securely in place during machining or cutting operations performed by the CNC machine.CNC chuck is one of the commonly used machine tool accessories, used to clamp the workpiece, in this article, we’ll explore some key aspects of a chuck used on CNC machines, including its definition, working principle, parts, types as well as the .Slash setup times, shorten cycle times, increase speeds and feeds, and maximize production on your CNC turning machines with Royal Quick-Grip™ CNC Collet Chucks. Royal Quick-Grip™ is the absolute best workholding solution for all turning jobs up to 4” diameter.Royal Accu-Length™ CNC Collet Chucks have been optimized for tool clearance and rigidity. Short lengths maximize the usable space inside the machining envelope, while extremely compact nose diameters reduce tool interference and .

National Machine Products has partnered with TDG Clamping Solutions to provide a range of large diameter chucks that help optimize CNC machining production. TDG is a leading provider of innovative clamping solutions that have been designed to meet the ever-changing needs of modern machining.Techniks Collet Chucks are designed to deliver excellent performance in a wide range of machining applications including milling, drilling, and tapping. Our exclusive PowerCOAT nuts come standard on all ER and TG Collet Chuck providing 75% more holding power on the tool shank vs. standard collet nuts for improved safety and reduce the potential .Choose from our selection of keyless drill chucks, keyed drill chucks, drill chuck arbors, and more. In stock and ready to ship.

GTS is an exclusive USA supplier of Autogrip power chucks, rotary cylinders, and accessories for CNC machining. We offer an entire line of Autogrip power chucks including 1,2,3 & 4 jaw power chucks, large thru-hole, heavy-duty power chucks and more!Choose from our selection of CNC chucks, including machine tool holding, lathe chucks, and more. In stock and ready to ship.Royal CNC Collet Chucks are proudly made in USA and are the preferred choice of all major machine tool builders. Every Royal CNC Collet Chuck includes a custom-machined drawtube connector for hassle-free installation, and with hundreds of chucks, collets, and accessories always in stock, virtually all Royal CNC Collet Chucks ship the same day .

A CNC chuck is a type of chuck specifically designed for use with Computer Numerical Control (CNC) machines. It is a clamping device that holds a workpiece securely in place during machining or cutting operations performed by the CNC machine.

CNC chuck is one of the commonly used machine tool accessories, used to clamp the workpiece, in this article, we’ll explore some key aspects of a chuck used on CNC machines, including its definition, working principle, parts, types as well as the .

Slash setup times, shorten cycle times, increase speeds and feeds, and maximize production on your CNC turning machines with Royal Quick-Grip™ CNC Collet Chucks. Royal Quick-Grip™ is the absolute best workholding solution for all turning jobs up to 4” diameter.Royal Accu-Length™ CNC Collet Chucks have been optimized for tool clearance and rigidity. Short lengths maximize the usable space inside the machining envelope, while extremely compact nose diameters reduce tool interference and .National Machine Products has partnered with TDG Clamping Solutions to provide a range of large diameter chucks that help optimize CNC machining production. TDG is a leading provider of innovative clamping solutions that have been designed to meet the ever-changing needs of modern machining.

Techniks Collet Chucks are designed to deliver excellent performance in a wide range of machining applications including milling, drilling, and tapping. Our exclusive PowerCOAT nuts come standard on all ER and TG Collet Chuck providing 75% more holding power on the tool shank vs. standard collet nuts for improved safety and reduce the potential .Choose from our selection of keyless drill chucks, keyed drill chucks, drill chuck arbors, and more. In stock and ready to ship.

what is a chuck engineering

front mount electrical box

types of collet chucks

$49.88

chucks for cnc machines|strong lathe chucks