components of cnc machine tools CNC milling is a subtractive manufacturing process where material is removed from a solid block to create parts. That being said, there are basic components in every CNC mill that allow it to function as intended. I’ve . Pure metal / Used as an alloy element for aluminum, lead, zinc, and other .

0 · structure of cnc machine tools

1 · schematic diagram of cnc machine

2 · parts made by cnc machine

3 · main parts of cnc machine

4 · main components of cnc machine

5 · cnc machine parts list pdf

6 · cnc machine components list

7 · block diagram of cnc machine

Go through the whole piece where we’ve explained different kinds of tools, methods, and scenarios on how to cut sheet metal. Best Tools for Cutting Sheet Metal: Tin .

structure of cnc machine tools

This post provided comprehensive information about CNC machines, including their components, functions, applications, limitations, and .

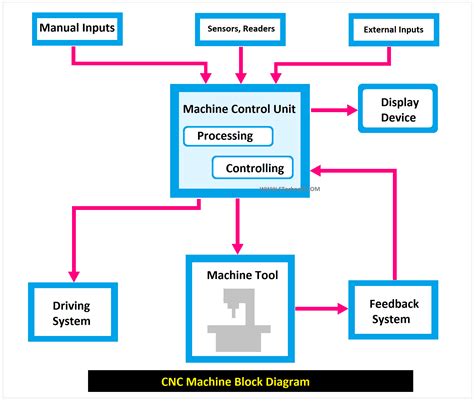

Different parts of the CNC machine, such as spindles or tool changers, can quickly create parts from raw materials. The machine follows orders from a computerized system that directs the machine tools to perform . CNC machines are complex assemblies and have many components, but there are 13 key components that you should be familiar with. These key components fall into two .In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine. It reads the G-code (the .

6x6x4 junction box weather proof

schematic diagram of cnc machine

CNC milling is a subtractive manufacturing process where material is removed from a solid block to create parts. That being said, there are basic components in every CNC mill that allow it to function as intended. I’ve .

Learn more about the different parts of a CNC machine and their functions. CNC (computer numerical control) machines are complex pieces of equipment designed to automatically manufacture parts from a wide range of materials that . With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders.This post provided comprehensive information about CNC machines, including their components, functions, applications, limitations, and advantages. To further explore the capabilities of CNC machines, we recommend reaching out to a representative from Runsom Precision. Different parts of the CNC machine, such as spindles or tool changers, can quickly create parts from raw materials. The machine follows orders from a computerized system that directs the machine tools to perform specific movements and operations according to a pre-programmed design.

CNC machines are complex assemblies and have many components, but there are 13 key components that you should be familiar with. These key components fall into two categories: the control system and the machine system. For CNC machines, the control system controls information, inputs, and outputs for the CNC machine.

In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine. It reads the G-code (the programming language for CNC) and converts it into electrical signals that control the machine's movements. CNC milling is a subtractive manufacturing process where material is removed from a solid block to create parts. That being said, there are basic components in every CNC mill that allow it to function as intended. I’ve created a list of the standard and most common CNC milling machine parts that you need to know about. Here are the 15 main parts of a CNC machine and their functions: Control Panel – The control panel is the interface between the operator and the machine. It allows the operator to input commands and control the machine’s movements. Spindle – The spindle is the rotating component that holds the cutting tool.

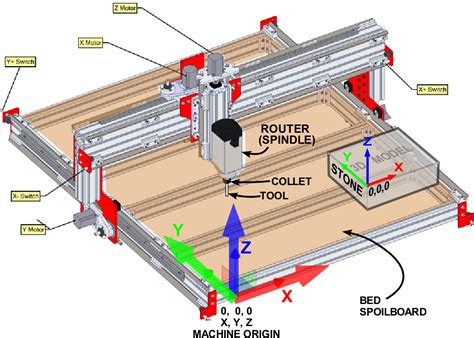

Three fundamental parts make up a computer numerical control (CNC) system: processing apparatus, often known as a machine tool, a machine control unit, and CNC software, which is a set of instructions. Machine tools comprise various CNC components, like the sliding table and the spindle. Operators use X and Y axes to control the table and the Z axis to control the spindle. Elements such as spindle drives and spindle motors are . Learn more about the different parts of a CNC machine and their functions. CNC (computer numerical control) machines are complex pieces of equipment designed to automatically manufacture parts from a wide range of materials that .

7 axis cnc grinding machine

With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders.

This post provided comprehensive information about CNC machines, including their components, functions, applications, limitations, and advantages. To further explore the capabilities of CNC machines, we recommend reaching out to a representative from Runsom Precision.

Different parts of the CNC machine, such as spindles or tool changers, can quickly create parts from raw materials. The machine follows orders from a computerized system that directs the machine tools to perform specific movements and operations according to a pre-programmed design.

CNC machines are complex assemblies and have many components, but there are 13 key components that you should be familiar with. These key components fall into two categories: the control system and the machine system. For CNC machines, the control system controls information, inputs, and outputs for the CNC machine.In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine. It reads the G-code (the programming language for CNC) and converts it into electrical signals that control the machine's movements. CNC milling is a subtractive manufacturing process where material is removed from a solid block to create parts. That being said, there are basic components in every CNC mill that allow it to function as intended. I’ve created a list of the standard and most common CNC milling machine parts that you need to know about. Here are the 15 main parts of a CNC machine and their functions: Control Panel – The control panel is the interface between the operator and the machine. It allows the operator to input commands and control the machine’s movements. Spindle – The spindle is the rotating component that holds the cutting tool.

Three fundamental parts make up a computer numerical control (CNC) system: processing apparatus, often known as a machine tool, a machine control unit, and CNC software, which is a set of instructions.

parts made by cnc machine

A single gang box, or 1 gang box, is wide enough to enclose only one outlet or switch. Single gang electrical box dimensions vary by manufacturer and type, but are about 2″ wide by 4″ high. Similarly, a double gang box, or 2 gang box, is sized to enclose two wiring devices.

components of cnc machine tools|block diagram of cnc machine