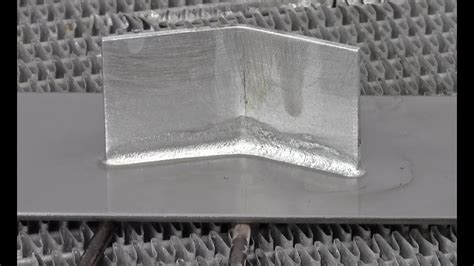

welding aluminized sheet metal Sheet metal welding is a vital aspect of manufacturing. Read on to learn the different welding methods for the sheet metal parts. Capabilities. CNC Machining. . and it’s suitable for most sheet metals, such as aluminum, steel, and stainless steel. This welding method is the go-to technique in the automotive and home improvement industry .

Additive manufacturing and CNC (Computer Numerical Control) are different processes. CNC involves removing material from a solid block using various tools, while additive manufacturing, or 3D printing, builds objects layer by layer from digital models.

0 · weld aluminum to stainless steel

1 · soldering aluminum to stainless steel

2 · silver solder aluminum to steel

3 · how to weld steel aluminum

4 · how to join steel aluminum

5 · how to bond aluminum steel

6 · how to attach aluminum steel

7 · does welding aluminum weaken it

Weatherproof junction boxes, as the name suggests, are designed to withstand exposure to harsh weather conditions. These boxes are typically made of durable materials, such as polycarbonate or aluminum, and feature a gasket or seal to provide a watertight enclosure.

Welding aluminized steel: Best practices. Q: Which process, filler rod, and shielding gas work best for welding aluminized steel? A: Aluminized steel resists fire, heat, corrosion, and oxidation. It’s used in many applications, such . In this comprehensive guide, we'll delve into the intricacies of MIG welding sheet metal and explore the ideal settings for different metal thicknesses. From. . (often referred to as C25) is preferred for welding stainless steel or .Aluminized steel is used in the manufacture of automotive exhaust parts and other items due to its heat- and corrosion-resistance. Since the aluminum is a coating on steel sheet metal, there is the possibility that the aluminum will begin to wear over time. MIG welders are used when welding aluminized steel and and . Another aspect of MIG welding aluminum that’s worth mentioning is pulse MIG. Using pulse MIG can produce high-quality welds, as it’s easier to control the weld puddle.. The pulsing action allows for much greater control of .

Sheet metal welding is a multifaceted craft that requires applying numerous techniques. Acquiring the requisite knowledge and skills is imperative to perform welding with optimal outcomes. . Regraining and blending are unnecessary when welding stainless steel with a brushed finish. Aluminum. To weld aluminum efficiently, it is necessary to .

Sheet metal welding is a vital aspect of manufacturing. Read on to learn the different welding methods for the sheet metal parts. Capabilities. CNC Machining. . and it’s suitable for most sheet metals, such as aluminum, steel, and stainless steel. This welding method is the go-to technique in the automotive and home improvement industry . MIG welding Aluminum sheet metal settings with Chart. Below is the MIG Welding Aluminum Sheet Metal Settings Chart which displays the recommended settings for welding aluminum sheet metal. Aluminum is a unique material to weld and requires special settings compared to other metals. Explore expert sheet metal welding services, offering precision, durability, and custom solutions for all your industrial and commercial needs. . For example, an aluminum sheet will require a thicker filler than steel. Use a Small Wire Diameter. It’s best to stick to smaller wire diameters when welding using solid wire electrodes, as in MIG .

6 Pack 5052 Aluminum Sheet Metal 12 x 12 x 1/64 (0.02”) Inch Thin Flat Plain Aluminum Plate Panel Covered with Protective Film, Heat Treatable Aluminum Sheet for Crafting Industry Welding: Amazon.com: Industrial & Scientific . Heat Treatable Aluminum Sheet for Crafting Industry Welding, 0.5mm. 4.8 out of 5 stars .

Unlike galvanized steel, aluminized steel can be sucessfully welded over. If aluminum caused the same problems as zinc, there would be no such thing as self-shielded FCAW as these electrodes use large amounts of aluminum to tie up the oxygen and nitrogen that the molten weld pool absorbs. Current and Monitoring: Spot welding aluminum-coated steel requires higher current and close process monitoring compared to cold-rolled steel. . Astm A463 aluminisierte Stahlsorte 40 Data Sheet It is a structural steel with a guaranteed minimum yield strength,. mehr lesen . 23 Juli 2024-07-23. Welding sheet metal is a very critical process within the modern concept of manufacturing. The construction of metal structures, pipelines, and tanks is among the most common applications for sheet metal welding. . In sheet metal welding, stainless steel, aluminum, and carbon steel are among the most commonly used materials, each presenting . Welding Aluminized Steel Aluminized steel can be welded using appropriate techniques which are described below. Oxyacetylene Welding Filler Metal Use a mild steel filler metal, 3/32" diameter, free of rust (American Welding Society classification A5.2). Do not use copper coated filler material. Welding Equipment: Use a number 3 or 4 tip.

At Bristol Welding Sheet Metal we provide the highest quality steel fabrications at the most competitive prices and will provide 100% commitment to achieving this from the start of your project right till the end.. We specialize in various materials including stainless steel, aluminium, mild steel, in a range of specifications such as sheet metal, RHS, CHS, Channels, universal .MIG is one of the best ways to weld 20-gauge sheet metal. MIG welding is one of the simplest to use for welding. It is an arc welding process that where you feed a solid wire electrode through a welding gun. . You can also use an inverted-based power source for working on a thin aluminum. Aluminum alloys for sheet fabrication are 5052 or 3003 . Welding nearly always causes some distortion: the metal in and around the weld shrinks as it cools, and this shrinking often upsets the shape of the metal. Sheet metal is particularly sensitive to this type of distortion (often . 3. Adjust Your Torch Angle. Changing the torch angle when MIG welding goes a long way to preventing burn-throughs. Make sure you adjust the angle to shorten the distance between the tip and the metal, no matter the .

5052H32 Aluminum Sheet Metal 12x17x1/4 Inch Thickness Large Aluminum Plate Covered with Protective Film, Heat Treatable Metal Aluminum Sheet for Welding, Industrial Visit the ACXFOND Store 4.6 4.6 out of 5 stars .

weld aluminum to stainless steel

soldering aluminum to stainless steel

Welding thin sheet metal can be challenging because you need to obtain adequate fusion while preventing distortion and burnthrough. The key skill is to control the heat across the sheet metal to prevent defects. This guide explains some of the ways to help get the best results when welding thin sheet metal.

Before initiating the plug welding sheet metal process, it's imperative to prepare the sheet metal to ensure optimal weld quality and structural integrity. . Welding Aluminized Steel: Expert Tips for Perfect Results; Can You Weld Galvanized Steel To Mild Steel: Expert Tips; Fusion Welding Plastic: Mastering Techniques for Stronger Bonds .

Save the Ar/CO2 for mig welding on aluminized. If you're going to go TIG, use straight argon, or a 75Ar/25Helium mix. Dont use the 75He/25Ar you would use on aluminum. Careful not to overheat the weld area, you'll compromise the aluminization and that can affect the corrosion resistance, critical for your intercooler application.

About this item . 6061 Aluminum Plate: Comes with 12pcs aluminum sheets, size - 4”x 4”x 1/8”(0.118") / 100 x 100 x 3 mm ; Durable Aluminum Sheet: The aluminum sheet metal made of 6061 aluminum alloy with high hardness, corrosion resistance, good oxidation effect; Aluminum plate 1/8in thick features excellent processing performance and welding performance

M&M Certified Welding Company is a steel and aluminum supplier for the Cleveland and Akron, Ohio areas. We carry a large stock of various sized steel, stainless steel, and aluminum, available for custom cutting, rolling, and bending for your next project. .The 2000 edition, D9.1M/D9.1:2000, Sheet Metal Welding Code, provides for maintenance of the document and updates to keep abreast of practices being encountered in sheet metal welding and joining processes since the last revision. The 2006 edition D9.1M/D9.1:2006, Sheet Metal Welding Code, also provides for maintena nce of the document and pre- The distortion in aluminum welding or copper alloys can be prevented by using proper welding sequence, welding direction, pre-setting, controlled heat input, etc. Detailed process of distortion control in aluminum involves: . For example, in case of thin sheet metal constructions with long welds it useful to apply intermittent welding in .This process assures a tight metallurgical bond between the steel sheet and the aluminum coating, producing a material with a unique combination of properties possessed neither by steel nor by aluminum alone. Aluminized steel shows a better behavior against corrosion and keeps the properties of the base material steel for temperature lower than .

Get a TIG (tungsten inert gas) welder with AC capability, not only DC. This is a type of welder that uses a tungsten electrode and an inert gas to shield the welding area. The precision achieved with this type of welder is crucial when working with aluminum, especially thin pieces. TIG welders are expensive, so consider contacting a local welding supply store or home .Don't have a shear at home or need to purchase sheet metal coupons quickly? We have what you need. Our Aluminum coupons are made 100% in house on our own shear so we can control quality and keep your metal in stock. Sold in packs of 12, 24, 48 or 96. For large orders please contact us before placing order. We proudly

silver solder aluminum to steel

how to weld steel aluminum

The Ford Super Duty uses the Open-C-frame to support the mutiple OEM configurations and the 2nd-unit aftermarket. See video for details. YouTube - Video 2008 Ford .

welding aluminized sheet metal|does welding aluminum weaken it