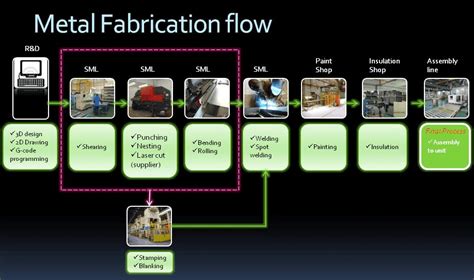

sheet metal process factories Sheet Metal Manufacturing Processes: Sheet metal manufacturing encompasses the fabrication of sheet metal components through cutting, bending, and shaping thin metal sheets into precise configurations and dimensions. This process commonly involves employing coating, cutting, bending, and assembly methodologies.

Buy WypAll 41041 X80 Cloths, BRAG Box, HYDROKNIT, Blue, 12 1/2 x 16 4/5 (Case of 160 Wipers) on Amazon.com FREE SHIPPING on qualified orders

0 · types of sheet metal fabrication

1 · sheet metal manufacturing techniques

2 · sheet metal manufacturing process types

3 · sheet metal manufacturing news

4 · sheet metal layout techniques

5 · how to fabricate sheet metal

6 · disadvantages of sheet metal

7 · basic sheet metal fabrication techniques

$23.00

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material .The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In . Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. Our customers use the Xometry Instant Quoting .Sheet metal fabrication is a highly versatile manufacturing process that creates complex parts and structures from metal sheets. From cellphones and kitchenware to submarines and rockets, numerous industries utilise this .

The Advantages Of Precision Sheet Metal Fabrication Process. The precision sheet metal fabrication process is ideal for high-quality manufacturing due to the various benefits it offers. For example: Customization: This process allows manufacturers to produce parts and components tailored to meet precise requirements. They just need to modify .Sheet Metal Manufacturing Processes: Sheet metal manufacturing encompasses the fabrication of sheet metal components through cutting, bending, and shaping thin metal sheets into precise configurations and dimensions. This process commonly involves employing coating, cutting, bending, and assembly methodologies.

The term “sheet metal fabrication” describes the process of transforming flat metal sheets into metal products and structural designs. Most sheet metal processing techniques include converting various sheet metal types into components and parts by employing precision equipment like a CNC machine and several forming methods.Shearing is a fundamental manufacturing process within sheet metal fabrication, serving as a primary method for cutting and shaping flat metal sheets. This process involves the use of shearing machines equipped with sharp blades, where the upper blade descends against the lower blade to cut through the sheet material. Shearing is particularly .

Watching the sheet metal manufacturing process may not be as interesting as, say, a caterpillar's metamorphosis into a butterfly. But it's beneficial to understand each stage from the purchasing/engineering point of view. There are six main stages, each important in creating the ideal finished product. The Sheet Metal Manufacturing Process 1 . Mastering sheet metal design is key to achieving both precision and efficiency in manufacturing sheet metal parts. By incorporating Design for Manufacturing (DFM) principles, you can streamline production, reduce costs, and maintain high-quality standards. Whether you’re working with steel, aluminum, or copper, understanding the nuances of sheet metal processing .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/or bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part.

53 Sheet Metal Process Engineer jobs available on Indeed.com. Apply to Process Engineer, Automation Engineer, Site Engineer and more! Skip to main content. . Analyzing operational data and production metrics of our manufacturing line. Generating process or product improvement ideas and creating, tracking, and evaluating experiments to test .This enables manufacturers to use them for products that require multiple metal forming techniques, such as bending, forming, piercing, and sheet metal blanking processes. Progressive These cold stamping dies move a strip of raw material through its various stations, with the die performing one stamping action per stroke at each one.The process begins with selecting a metal sheet, cutting it into the desired shape, and subjecting it to various treatments to create a durable product. These treatments include bending, rolling, and welding. Sheet metal fabrication is cost-effective and capable of producing complex geometries.

What Is Sheet Metal Fabrication? The sheet metal fabrication process takes many steps and requires a team to complete the process. We usually use steel, aluminum, stainless steel, and similar metals for manufacturing, as the industries that use our services need reliable products. Fabricating sheet metal involves stretching, cutting, and bending the metal to create the .Sheet Metal Stamping is a low-cost high-speed manufacturing process that produces a high volume of identical metal components, which has contributed importan.

Sheet metal fabrication is a widely used manufacturing process that transforms flat sheets made from various metals, mainly steel, and aluminum, into functional shapes and structures. It does so by cutting, punching holes, and folding the metal sheets to achieve the.

RapidDirect company deals with sheet metal fabrication.Its base is in Shenzhen, China, and has operated for over fifteen years. Praising the company for its professionalism and the potential list of services, it should be . Sheet metal manufacturing is a very common process that involves the fabrication of metal parts or components from flat sheets of various metals, such as steel, aluminum, or copper. It is a widely used method in various .Sheet metal stamping is a process of using tools and dies to press and stamp metal blanks into their desired final shape. Sheet metal services are often used across a variety of industries such as automotive, aerospace, consumer electronics, and electronic manufacturing.. Zetwerk provides custom precision sheet metal stampings from coiled or blanked sheet metal.

types of sheet metal fabrication

The die holds the sheet metal during the process while the punch delivers a “blanking force” through the metal. The material removed is the desired component, while the material that remains on the die is the blank stock left. . Pre-plated steel ensure easy sheet metal manufacturing due to increased formability and weldability. This sheet .

During the process of sheet metal manufacturing, if a sheet metal part requires welding, PMF is more than capable of filling that need. We are equipped with 2 spot welding stations and we also employ traditional welders who are experienced in both MIG and TIG welding practices. In addition, in an effort to lessen the cost associated with .Galaxy’s rapid sheet metal prototyping is a process that allows for the quick and cost-effective production of sheet metal prototypes. It involves using specialized techniques and equipment to rapidly fabricate and iterate on sheet metal parts or components. Sheet metal machines are widely used in various manufacturing industries for shaping, cutting, and forming sheet metal into different components. . Stamp press technology, also known as stamping or pressing, is a manufacturing process that utilizes a press to shape or cut materials into desired forms. This process involves the use of a die .

Sheet metal manufacturing plays a crucial role in fulfilling the requirements of various engineering processes. When engineering specifications dictate the use of sheet metal, it undergoes a fabrication process. Sheet metal crafting encompasses a range of techniques including shearing, bending, notching, shrinking, and beading.

Here at Redstone Manufacturing, we simplify the process and reduce the risk of working with foreign manufacturers. With headquarters in the USA and sheet metal manufacturing facilities in Mexico, our buyers receive guaranteed delivery backed by a US-based company with a US-based sales force they can trust. Combined with Redstone Manufacturing . Sheet metal processing is a vital part of the metal machining industry. Though it might seem simple, the work has high importance in the manufacturing industry. Any sheet metal process done to the sheets is a small piece of the more extensive manufacturing process. Each process is an individual service that forms the more extensive process.Sheet Metal laser cutting. You may use the laser cutting method to cut a variety of materials, including steel and aluminium sheets, as well as three-dimensional objects like profiles and tubes.. More than two decades ago, technology launched laser cutting as an industrial technique. The study aims at a high-energy, highly focused laser beam at a workpiece during the cutting .Our sheet metal manufacturing facilities located in China, Mexico, India, Taiwan, and Brazil are certified in production quality and consistency. . Sheet metal fabrication is a fundamental process for manufacturing metal products. It involves taking metal sheets and forming them into the desired shape and size. Cutting, forming, and finishing .

sheet metal manufacturing techniques

Model: X50-B. Composition: Steel Application: Interior Install Time (hrs): 0.30 QuickShip: Yes Weight: 19 lbs Dimensions: 12.5D x 18.5W x 10.5H in.

sheet metal process factories|how to fabricate sheet metal