sheet metal fabrication process factory Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: . A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

0 · types of sheet metal fabrication

1 · sheet metal manufacturing process types

2 · sheet metal layout drawings

3 · sheet metal bending chart

4 · how to fabricate sheet metal

5 · disadvantages of sheet metal

6 · design guidelines for sheet metal

7 · basics of sheet metal fabrication

Vingud Electric Lunch Box, 3 in 1 Heated Lunch Box for adults, Portable Heating Lunch Box with 1.5L Removable Stainless Steel Container for Office/Car/Truck, 110V 24V 12V, 80W-60W, .

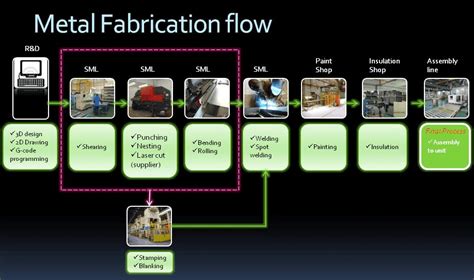

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a . Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly .The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and .Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: .

The art and science of sheet metal fabrication involve a series of meticulous processes, from designing and cutting to bending and welding. This article unpacks the top ten technological processes, guiding you through each .What is Sheet metal fabrication? A complete guide on processes, applications, pros, and cons. Discover essential tips and techniques in our comprehensive guide to sheet metal fabrication for both beginners and professionals.

Anupreethi M. Precision sheet metal fabrication is a critical process that plays a crucial role in various industries, including aerospace, medical devices, and electronics manufacturing. From design to the final product, precision . What is Sheet Metal Fabrication? Sheet metal fabrication is the process of forming flat metal sheets into the desired parts and products by cutting, folding, bending, and assembling.

types of sheet metal fabrication

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high strength-to-weight ratio, durability, and versatility.Sheet metal fabrication is a process that involves the manipulation of metal sheets to create various structures and components. In the Philippines, this industry plays a crucial role in the manufacturing sector, contributing to the country's economic growth and providing employment opportunities for skilled workers. In this blog post, we will .Sheet metal fabrication is a series of manufacturing processes used to convert sheet metal into functional parts. Die Casting. Die casting is a metal manufacturing process in which molten metal is pressed under high pressure .

Sheet metal fabrication is a highly versatile manufacturing process that creates complex parts and structures from metal sheets. From cellphones and kitchenware to submarines and rockets, numerous industries utilise this .

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high strength-to-weight ratio, durability, and versatility. . Cutting is a fundamental process in sheet metal fabrication. Different cutting methods are used based on the complexity of the .Learn about our intricate sheet metal process for manufacturing custom projects and schedule your custom sheet metal fabrication with PMF today! 919-231-8648 [email protected] Request a Quote. Home; . The steps for sheet metal processing or the fabrication process typically remain the same no matter where you go: Punching/CNC Press Brake WeldingPrecision meets creativity with our expert sheet metal fabrication services. Superior craftsmanship to bring your vision to life. Capabilities. Sheet Metal Fabrication . Product proofing is an essential part of the manufacturing process that can help businesses ensure the quality and consistency of their products while minimizing risks and . Fabrication of sheet metal is a manufacturing process that involves shaping and manipulating thin sheets of metal into desired parts and components. It typically includes cutting, bending, forming, and assembling metal sheets to create various products such as enclosures, brackets, panels, and many more.

Our skilled engineering team is equipped to manage an entire sheet metal fabrication process, from laser cutting to assembly to final delivery. We believe IMS is fabricating the only way a company can if it wants to be around for the long-term, high quality, quick turnaround, strategic labor, and smart operations.Esteem Metal Fabrication Sdn Bhd was established in 2012 n Johor Bahru, Malaysia. We provide custom made order precision parts, fabrication and sheet metal processing and relevant engineering services. Before incorporated the Company, the founder was worked for several precision sheet metal fabrication companies for over 11 years. Introduction. Sheet metal manufacturing is a fundamental part of modern industry, transforming raw metal into essential components for a wide range of products, from consumer electronics to heavy machinery. This precision-driven process transforms flat metal sheets into intricate components. Over the decades, sheet metal manufacturing has evolved from manual .

These qualities make it ideal for high volume manufacturing across many industries. Sheet Metal Materials . Sheet metal fabrication utilizes a variety of metals, each with properties that make them suitable for different applications. . Sheet metal fabrication is the process of shaping thin sheets of metal into useful structures and products .Please rest assured to buy bulk high quality sheet metal fabrication at competitive price from our factory. For customized service, contact us now. [email protected] +86-571-83737375. Language. . Metal casting is a manufacturing process that involves pouring molten metal into a mold to create a 3D metal piece. Once the metal and the mold . Choosing the Right Sheet Metal Fabrication Process | 5 Key Factors That Will Influence Your Decision. The right sheet metal fabrication process is pivotal to the success of your project. Careful consideration of the metal type, fabrication technique, finishing options, and production requirements will guide you in making informed decisions. 1.

Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. This transformation is achieved through a series of techniques such as cutting, punching, folding, bending, stamping, welding, and finishing. . Sheet Metal Fabrication vs Other Metal Manufacturing .

Our 60,000-square-foot state-of-the-art manufacturing facility, quality equipment and experienced metal fabricators enable us to handle even the most complex sheet metal fabrication project. Whether you need a prototype or a large-scale .

As a professional sheet metal fabrication factory in china fabrication sheet , HSJ provides customized sheet metal fabrication services of precision stamping parts, of which the tolerance is only +/- 0.01mm. . Sheet metal is metal formed by .Sheet metal is highly compatible with the process, allowing custom sheet metal fabricators to create diverse products with optimal design versatility and reliable quality. The ideal fabrication partner will offer the manufacturing and secondary finishing services you need with the precision necessary to ensure tight-tolerance, high-performance .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/or bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part.

Shearing Cutting Bending Punching Assembling Sheet metal fabrication is defined as the manufacturing process of shaping sheet metal according to functional needs. Sheet metal is one of the most ideal materials for a wide array of industries because it . Sheet metal fabrication is a manufacturing process that utilizes sheets of metal to create a wide range of different parts and products. However, the term “sheet metal fabrication” specifically refers to the numerous manufacturing techniques used with sheet metals, including laser cutting, bending, welding, and forming.

sheet metal manufacturing process types

Since 1968, R&M Manufacturing has been a leading producer of precision sheet metal components. With our 50+ years of experience in sheet metal fabrication, our methods are repeatable and economical. We can shape metal into any design with our state-of-the-art equipment in our cutting-edge 100,000-square-foot manufacturing facility.

Sheet metal fabrication is a manufacturing process that involves cutting, bending, and assembling metal sheets to create various components and structures. The process begins with a flat sheet of metal, which can be made from various materials such as steel, aluminum, brass, or copper. . The first step in the sheet metal fabrication process . These metals are available in sheet metal, pipes, bars, or tubes, with sheet metal being the most common form. Key Metal Fabrication Techniques. Raw metal materials need to go through a fabrication process to be usable for manufacturing and assembly. Take a look at the key techniques below! CuttingWhat Is Sheet Metal Fabrication? The sheet metal fabrication process takes many steps and requires a team to complete the process. We usually use steel, aluminum, stainless steel, and similar metals for manufacturing, as the industries that use our services need reliable products. Fabricating sheet metal involves stretching, cutting, and bending the metal to create the .

In this blog post, we will explore the key considerations and best practices for designing a sheet metal factory layout that allows for seamless operations and optimal output. 1. Analyzing Workflow. Before designing the layout, it is essential to analyze the workflow of the sheet metal fabrication process. Discover the top 10 CAD/CAM software solutions for sheet metal and tube processing. Boost productivity, streamline workflows, and create advanced parts with industry-leading design and manufacturing tools. Find the right fit for your metalworking business.

I have over ten years of professional experience in sheet metal fabrication, specializing in laser cutting, bending, welding, and surface treatment techniques. As the Technical Director at Shengen, I am committed to solving complex manufacturing challenges and driving innovation and quality in each project.

customized metal stamping bending part factories

sheet metal layout drawings

Old vintage metal box measures approx. 10-1/8" Long x 4-3/4" Wide x 1-3/8" High. Button opens the box. Box snaps and closes as it should. Box is in PRE-OWNED condition. Has finish wear, scratches, pai.from

sheet metal fabrication process factory|types of sheet metal fabrication