bend deduction formula in sheet metal The Bend Deduction Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Deduction. You will need to know your Material Thickness . how do you weld sheet metal with a stick welder? Before you begin the process of welding a very thin sheet, there are a few things you must have. The first is a DC welder which can go as low as 20-25 amps.

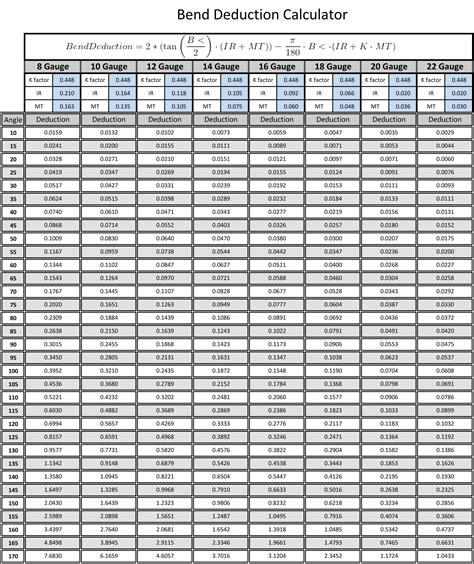

0 · stainless steel bend deduction chart

1 · sheet metal bending allowance charts

2 · sheet metal bend deduction chart

3 · sheet metal bend calculation formula

4 · how to calculate bend length

5 · how to calculate bend deduction

6 · how to calculate bend allowance

7 · bend deduction chart pdf

WELL Trigger / Reinforced Metal Block for L96 / MAUSER compatible CYBERGUN MAUSER SR / SR PRO / PRO TACTICAL SR / WELL MB-01 / MB-04 / MB-05 / MB-08.

The Bend Deduction Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Deduction. You will need to know your Material Thickness .

A bend deduction (BD) is the value subtracted from the flat blank for each bend in the part, and there may be more than one. Bend deductions differ depending on the part itself, different bend angles, and/or inside radii. Total bend deduction in sheet metal parts can be calculated by using the following formula: Sheet Metal Flat Length = Length A + Length B – Bend Deduction. Bend Deduction = .

Bend Deduction is actually the measurement of the length that you will have to deduct from the total length of the flanges of the final sheet metal component, in order to get the correct length of the flat pattern that you need .

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Let’s start with the formulas for bend allowance and bend deduction. Bend Allowance = Angle (Π/180) (BendRadius+KFactor (Thickness)) Bend Deduction = 2 (BendRadius+Thickness)Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming. Considering the Bend Deduction and Bend Allowances is a critical first step in designing sheet metal parts as it affects nearly every following step in the fabrication process. More so, it will allow you to achieve the correct size .

Our bend deduction calculator helps you calculate the correct values for your sheet metal bending projects, ensuring accurate results and minimal waste. Try it out for free today!The Bend Deduction Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Deduction. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K).

A bend deduction (BD) is the value subtracted from the flat blank for each bend in the part, and there may be more than one. Bend deductions differ depending on the part itself, different bend angles, and/or inside radii.

stainless steel bend deduction chart

sheet metal bending allowance charts

phillips clear vu junction box

Total bend deduction in sheet metal parts can be calculated by using the following formula: Sheet Metal Flat Length = Length A + Length B – Bend Deduction. Bend Deduction = Length A + Length B – Sheet Metal Flat Length Want to learn how to calculate bending allowance, bending deduction, and K-factor for sheet metal bending? Our guide offers a step-by-step process and practical tips to help you achieve accurate and precise bending results every time. Bend Deduction is actually the measurement of the length that you will have to deduct from the total length of the flanges of the final sheet metal component, in order to get the correct length of the flat pattern that you need to create for that component.

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Let’s start with the formulas for bend allowance and bend deduction. Bend Allowance = Angle (Π/180) (BendRadius+KFactor (Thickness)) Bend Deduction = 2 (BendRadius+Thickness)Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming.

Considering the Bend Deduction and Bend Allowances is a critical first step in designing sheet metal parts as it affects nearly every following step in the fabrication process. More so, it will allow you to achieve the correct size and dimensions needed in the flat pattern. Our bend deduction calculator helps you calculate the correct values for your sheet metal bending projects, ensuring accurate results and minimal waste. Try it out for free today!

The Bend Deduction Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Deduction. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K).

A bend deduction (BD) is the value subtracted from the flat blank for each bend in the part, and there may be more than one. Bend deductions differ depending on the part itself, different bend angles, and/or inside radii.Total bend deduction in sheet metal parts can be calculated by using the following formula: Sheet Metal Flat Length = Length A + Length B – Bend Deduction. Bend Deduction = Length A + Length B – Sheet Metal Flat Length Want to learn how to calculate bending allowance, bending deduction, and K-factor for sheet metal bending? Our guide offers a step-by-step process and practical tips to help you achieve accurate and precise bending results every time.

Bend Deduction is actually the measurement of the length that you will have to deduct from the total length of the flanges of the final sheet metal component, in order to get the correct length of the flat pattern that you need to create for that component. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Let’s start with the formulas for bend allowance and bend deduction. Bend Allowance = Angle (Π/180) (BendRadius+KFactor (Thickness)) Bend Deduction = 2 (BendRadius+Thickness)Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming.

phl metal fabrication

sheet metal bend deduction chart

Welding thin metal poses a unique set of challenges, requiring a delicate balance between heat application and precision to avoid warping or burn-through. Whether you’re working with sheet metal, thin tubing, or other lightweight materials, the key to successful welding lies in mastering the nuances of technique and equipment settings.

bend deduction formula in sheet metal|how to calculate bend allowance