how to fabricate a metal cone Whether you need to replace a damaged cone or create a custom design for your project, learning how to make a sheet metal cone can save you time and money. In this step . A single gang box, or 1 gang box, is wide enough to enclose only one outlet or switch. Single gang electrical box dimensions vary by manufacturer and type, but are about 2″ wide by 4″ high. Similarly, a double gang box, or 2 gang box, is sized to enclose two wiring devices.

0 · sheet metal layout cone

1 · sheet metal cone rolling calculation

2 · how to layout a cone

3 · how to fabricate a cone

4 · formula for making a cone

5 · develop a cone sheet metal

6 · creating a cone layout

7 · cone layout formula

The amount of coverage a sheet of metal roofing will provide can vary greatly depending on the type and gauge of metal being used. For example, standard corrugated galvanized steel roofing, which typically measures between 24 and 28 gauge, can cover 12 .

sheet metal layout cone

Here is one way to make a cone from flat stock. I used aluminum sheet coil but you could use paper or any flat material. You can find cone calculators online, I used this particular cone . This video shows how to make cones from 1/8-inch (3.2mm) steel, using simple shop-made equipment. Whether you need to replace a damaged cone or create a custom design for your project, learning how to make a sheet metal cone can save you time and money. In this step .

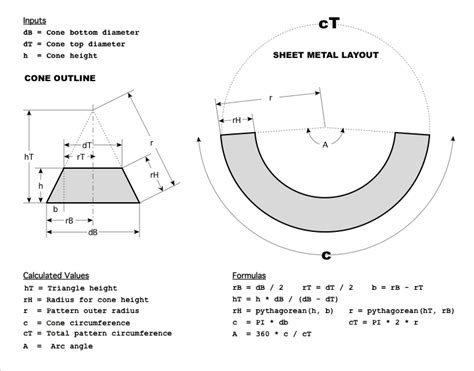

Learn how to layout a sheet metal cone and the formula, these numbers can be replaced with your dimensions.

sheet metal cone rolling calculation

how to layout a cone

The first step in fabricating a cone from sheet metal is determining the dimensions of the cone you want to create. This includes the base diameter, top diameter (if it's a frustum), and the height . Rolling a Long Cone from Sheetmetal. Ron Covell. 207K subscribers. Subscribed. 4.4K. 134K views 1 year ago. See how to roll a long cone from 16-gauge (1.6mm) sheetmetal. .more. Covell. Sheet metal cones are commonly used in a variety of industrial and commercial applications, including ductwork, chimneys, and tanks. Fabricating a cone with sheet metal requires precision and expertise. In this .

Your sheet metal cone is now complete and ready for use in your project. In this guide, we've covered the essential steps for fabricating a sheet metal cone. With the right tools, materials, .

We’re going to take a look at what applications a metal cone can have, what type of cones it’s possible for CSM to produce for you, and some of the things you’ll need to consider before having your cones designed and produced. To fabricate a cone from sheet metal, follow these steps: Draw the flat pattern of the cone on the sheet metal using a compass and ruler. Cut out the flat pattern using tin snips. #MetalFabricationTips #MetalFabTips #KevinCaronArtFrom http://www.kevincaron.com - Artist Kevin Caron shows the easy way he found to make a cone for his late.

See how to roll a long cone from 16-gauge (1.6mm) sheetmetal.You can help me create new videos by becoming a Patreon. Here’s the link:https://www.patreon.com.So a cone would be fine, but the parabolic shape requires curves in two directions and I'm not sure how that's gonna happen. Still I feel like given the sheer amount of metalworking tools there ought to be a way to simply make a parabolic .

blacktoe 4x8 cnc machine

https://mikesinventions.etsy.com Making Cone shapes can be Frustrating. This video shows you how to lay out your flat pattern so that you can wrap your own f.

About Sheet Metal ConesSheet metal cones are commonly used in a variety of industrial and commercial applications, including ductwork, chimneys, and tanks. Fabricating a cone with sheet metal requires precision and expertise. In this blog post, the experts at Vishwambhari Engineering will guide you through the steps we take when fabricating a cone .To fabricate a sheet metal cone, you'll need: Sheet metal (preferably steel, aluminum, or copper) A compass or a large piece of string . Tape measure . Straight edge or ruler . Metal cutting shears or a plasma cutter . Metal file or deburring tool . Welder (MIG, TIG, or oxy-acetylene) Video title: How to Roll a Cone – Midland FabricationIn this video students James & Luke talk us through how to roll a cone in a set of pinch plate rolls. Th.This development Angle is used to layout cone fabrication layout markings or Flat Pattern Markings. . Pressure Vessel Manufacturing Industry, Piping Industry, Sheet Metal Industry, Heavy Equipment Fabrication Industry or any similar Industry. Cone Calculator helps to Fabrication Engineer, Fabrication Fitter, Production Engineer, Quality .

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Rolling a metal cone out of sheet metal may be a little easier than you may think. By determining the length of the slanted side and the circumference at the wide end of your cone, you can quickly and easily produce a cone exactly the size you want it to be out of a flat piece of sheet metal.

Here a video how to make an Eccentric ReducerSheet metal cone fabrication is the process of creating conical shapes from flat sheets of metal. Cones are three-dimensional geometric figures that have a circular base and taper to a point at the apex. Sheet metal cones are commonly used in various industrial, commercial, and DIY applications, such as in the manufacturing of tanks, funnels .In this video, I show how to make a reducer from sheet metal

We discuss the process for making a pattern to transfer to metal. Cones are used to make bi-cone beads and mounts to set stone in.-----Thank you for watching.

Cone Calculator is used for all types of Cones Flat Pattern Layout Calculations or Cone Fabrication Layout Development for cones fabrications. . Industry, Process Equipment Manufacturing Industry, Pressure Vessel Manufacturing Industry, .

Sheet metal cones are versatile and indispensable in a wide range of applications, from ductwork in HVAC systems to chimney caps and funnels. Whether you need to replace a damaged cone or create a custom design for your project, learning how to make a sheet metal cone can save you time and money. In this step-by-step guide, we will walk you through the . SolidWorks II Sheet Metal II Four Ways To Create Sheet Metal - ConeIn this video, I am going to explain Four difference ways to create Sheet Metal - Cone----.

Video showing the processes involved in producing a steel cone. It a job that requires a little skill and a lot of patience! Video showing the processes involved in producing a steel cone. It a . "Blacksmith How to make a metal Pinecone decorative fall sculpture build forged sheet metal" Hey everyone and thank you for joining me again, Sorry for the d.How to make a cone 11-10-2002, 01:36 AM. I need help to machine a cone that must be mounted on the shaft of an electric motor. The cone must be 3inch long by 2inch wide. . Set your compound rest to this length. have a piece of metal about 5 inch long. Another way to hold is to tap one end of the material about 3/4 inch deep and put a 3/4 - 16 . A quick how-to showing my favorite way to make a cone from 3 measurements. All you need to know is the small diameter, the large diameter and the height. Che.

how to build a cone? complete Method to make templateA concentric reducer is used to join pipe sections or tube sections on the same axis.The concentric redu.How to fabricate sheet metal. As explained, sheet metal fabrication is a complex process that requires years of training and experience to perfect. It involves multiple stages, starting with design. If you’re keen to learn more about sheet metal fabrication, discover more about it in our ultimate guide to sheet metal fabrication here. Step 1 .

How to make a CONE INVISIBLE in FORTNITE.Three easy simple steps to become a MASTER at making builds invisible!Subscribe and Like for more content and vide.Cone-shaped metal is used for making jingling cones. Making Indian jingle cones is simple if you have the right tools and materials. Indian jingle cones are used to adorn Indian jingle dance dresses. When jingle cones are worn on Indian jingle dresses by dancers, together they make a jingling sound. Native American Indians believe that the .

The easiest way to make a cone is to start with a semicircle, then overlap the straight edges until they form a cone shape. If you want to get more specific, however, you should start with a circle instead, then cut a wedge out. . If making a felt, foam, plastic, or metal cone, use hot glue instead. Fabric glue may work for foam cones as well .This cannot directly make a conic bend though. You may be better off measuring the length of what will become the circular top and circular bottom of the cone from the flat pattern then use that to construct the cone directly as a 3D sheet metal piece to flatten (like this: GoEngineer - SOLIDWORKS: Sheet Metal Cone).

how to fabricate a cone

I was thinking of painting over the gold with metallic silver acrylic fabric paint. Anyone have experience with this or advice? Getting so many conflicting things from google.

how to fabricate a metal cone|how to layout a cone