cnc edm spark machine The erosive effect of electrical discharges was first noted in 1770 by English physicist Joseph Priestley.Die-sink EDMTwo Soviet . See more View credits, reviews, tracks and shop for the 1994 CD release of "Blackbox - Wax Trax! Records: The First 13 Years." on Discogs.

0 · wire edm milling

1 · wire edm machine types

2 · wire edm machine price

3 · wire edm machine manufacturers

4 · wire edm machine diagram

5 · wire cut edm machine

6 · graphite wire edm machine

7 · best wire edm machines

Circuit breakers trip to stop overheating, electrical fires, and damage to electrical parts. Plugging in too many devices can cause the circuit to become overloaded, so the breaker trips to cut off the power.If you have electrical experience and can determine which device is causing the short, replace the device or correct the loose wire. If you’re not experienced, or you smell something burning or see scorch marks on your .

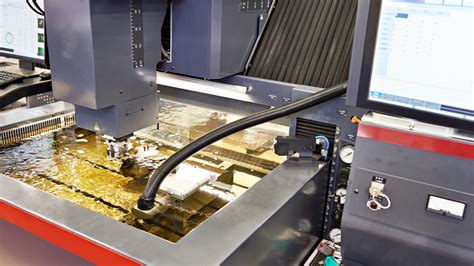

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring . See more

The erosive effect of electrical discharges was first noted in 1770 by English physicist Joseph Priestley.Die-sink EDMTwo Soviet . See moreThe first serious attempt at providing a physical explanation of the material removal during electric discharge machining is perhaps that of Van Dijck. Van Dijck presented a thermal model together with a computational simulation to explain the . See morePrototype productionThe EDM process is most widely used by the mold-making, tool, and die industries, but is becoming a . See more

Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with . See moreDifficulties have been encountered in the definition of the technological parameters that drive the process.Two broad . See moreSinker EDMSinker EDM, also called ram EDM, cavity type EDM or volume EDM, consists of an electrode and workpiece submerged in an insulating liquid such as, more typically, oil or, less frequently, other dielectric fluids. The electrode and . See moreEDM is often compared to electrochemical machining. Advantages of EDM include:• Ability to machine complex shapes that would otherwise be difficult to produce with conventional cutting . See more

DMNC Provides Complete Solution of EDM Machining Technology With 30+ Years' Experience, Continuous Innovation, Strict Quality Control, and Swift Service. CNC EDM machines for sale including CNC EDM . Electrical discharge machining (EDM) is a process that applies CNC technology with electrical sparks to form simple or complex shapes. Sometimes referred to as spark machining, EDM creates profiles when current . Sep 21, 2020

Electrical discharge machining, also colloquially known as spark machining, wire erosion or spark eroding, is a non-traditional machining process that relies on electrical discharge (or electric sparks) to remove particles of .Transform Your Machining Process with DMNC CNC EDM Machine. DMNC-EDM is a well-experienced professional manufacturer and supplier of CNC EDM machine including die sinking machine, wire cut machine, small hole EDM .Electrical Discharge Machining (EDM) . The spark erosion process follows a precise sequence where an ionization channel develops into a plasma channel of superheated gas. Material .Spark machining is a Substractive machining process that attains the desired shape by producing sparks that melt tiny portions of a metal workpiece. Electrical Discharge Machining (EDM) is another term for that method, spark eroding, .

The process of spark erosion enables us to machine hardened or difficult to machine conductive materials to create shapes and forms that couldn’t be achieved with conventional CNC/Manual milling or turning.

Electrical Discharge Machining, also referred to as spark machining, is an alternative to traditional machining that uses thermal rather than mechanical forces to remove material. Specifically, a hot electrical spark is .Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). [1] DMNC Provides Complete Solution of EDM Machining Technology With 30+ Years' Experience, Continuous Innovation, Strict Quality Control, and Swift Service. CNC EDM machines for sale including CNC EDM die sinking machine, EDM wire cut Machine, small Hole EDM drilling machine, and EDM parts. Inquiry now!

wire edm milling

Electrical discharge machining (EDM) is a process that applies CNC technology with electrical sparks to form simple or complex shapes. Sometimes referred to as spark machining, EDM creates profiles when current discharges and sparks occur between two electrodes—the wire and the workpiece. ADV series new generation CNC EDM spark erosion machine is designed for automation. Equipped with robot and electrode and workpiece store, CNC EDM machine itself can realize small parts, large quantity, and man-free production.

Electrical discharge machining, also colloquially known as spark machining, wire erosion or spark eroding, is a non-traditional machining process that relies on electrical discharge (or electric sparks) to remove particles of material from a workpiece made from a conductive material, such as steel, titanium, aluminum, brass, and more.

Transform Your Machining Process with DMNC CNC EDM Machine. DMNC-EDM is a well-experienced professional manufacturer and supplier of CNC EDM machine including die sinking machine, wire cut machine, small hole EDM drilling machine and EDM parts. Inquiry now!Electrical Discharge Machining (EDM) . The spark erosion process follows a precise sequence where an ionization channel develops into a plasma channel of superheated gas. Material removal occurs through: . The evolution progressed from basic Lazarenko Circuits to modern systems featuring CNC integration, Wire-EDM technology, and advanced .Spark machining is a Substractive machining process that attains the desired shape by producing sparks that melt tiny portions of a metal workpiece. Electrical Discharge Machining (EDM) is another term for that method, spark eroding, burning, die sinking, wire burning, and wire erosion.

The process of spark erosion enables us to machine hardened or difficult to machine conductive materials to create shapes and forms that couldn’t be achieved with conventional CNC/Manual milling or turning. Electrical Discharge Machining, also referred to as spark machining, is an alternative to traditional machining that uses thermal rather than mechanical forces to remove material. Specifically, a hot electrical spark is what removes material from the workpiece.Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). [1]

DMNC Provides Complete Solution of EDM Machining Technology With 30+ Years' Experience, Continuous Innovation, Strict Quality Control, and Swift Service. CNC EDM machines for sale including CNC EDM die sinking machine, EDM wire cut Machine, small Hole EDM drilling machine, and EDM parts. Inquiry now! Electrical discharge machining (EDM) is a process that applies CNC technology with electrical sparks to form simple or complex shapes. Sometimes referred to as spark machining, EDM creates profiles when current discharges and sparks occur between two electrodes—the wire and the workpiece. ADV series new generation CNC EDM spark erosion machine is designed for automation. Equipped with robot and electrode and workpiece store, CNC EDM machine itself can realize small parts, large quantity, and man-free production. Electrical discharge machining, also colloquially known as spark machining, wire erosion or spark eroding, is a non-traditional machining process that relies on electrical discharge (or electric sparks) to remove particles of material from a workpiece made from a conductive material, such as steel, titanium, aluminum, brass, and more.

Transform Your Machining Process with DMNC CNC EDM Machine. DMNC-EDM is a well-experienced professional manufacturer and supplier of CNC EDM machine including die sinking machine, wire cut machine, small hole EDM drilling machine and EDM parts. Inquiry now!

wire edm machine types

install doorbell transformer in junction box

Electrical Discharge Machining (EDM) . The spark erosion process follows a precise sequence where an ionization channel develops into a plasma channel of superheated gas. Material removal occurs through: . The evolution progressed from basic Lazarenko Circuits to modern systems featuring CNC integration, Wire-EDM technology, and advanced .

Spark machining is a Substractive machining process that attains the desired shape by producing sparks that melt tiny portions of a metal workpiece. Electrical Discharge Machining (EDM) is another term for that method, spark eroding, burning, die sinking, wire burning, and wire erosion.The process of spark erosion enables us to machine hardened or difficult to machine conductive materials to create shapes and forms that couldn’t be achieved with conventional CNC/Manual milling or turning.

install exterior light without junction box

wire edm machine price

Metal domes are often used in keypads, remote controls, and other devices where precise control is required. They are typically mounted on a printed circuit board or other substrate, and are connected to the device’s circuitry through conductive pads on the bottom of the dome.

cnc edm spark machine|wire edm machine diagram