how to create sheet metal parts in solidworks There are multiple methods for making sheet metal parts in Solidworks using the Sheet Metal tab. In this article, we will look at using the Sketched Bend feature and also the .

jinshiling Manufacturing has a reputation for machining quality ptfe parts. We can machine intricate parts on our CNC machines and CNC turning centers. PTFE (more commonly known as Teflon) is an extremely resilient plastic, ideal for machine parts that require high impact strength and durability.

0 · solidworks sheet metal tutorial

1 · solidworks sheet metal tools

2 · solidworks sheet metal tab

3 · solidworks sheet metal drawing pdf

4 · solidworks sheet metal add in

5 · solidworks convert to sheet metal

6 · sheet metal design in solidworks

7 · add sheet metal tab solidworks

Since 1990 J&J Metal Spinning has been serving the US with quality parts and exceptional service. J&J Metal Spinning's team of production engineers has over 50 years of metal spinning experience and a deep knowledge of the metal fabrication industry.

solidworks sheet metal tutorial

You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, .To create a multibody sheet metal part: Create new bodies in an existing sheet .When designing sheet metal parts, the order preference for use of feature tools .

Sheet Metal Design in SolidWorks for Beginners | Step-by-Step TutorialIn this comprehensive SolidWorks tutorial, we'll walk you through the fundamentals of s.

Go start to finish creating an in-context sheet metal enclosure, making cut outs for parts, and creating a drawing of the part. .more. When you're creating parts, i.

There are multiple methods for making sheet metal parts in Solidworks using the Sheet Metal tab. In this article, we will look at using the Sketched Bend feature and also the . In this lesson, you create the sheet metal part. This lesson demonstrates: 1.Creating a base flange 2.Adding a miter flange 3.Mirroring the part and creating. different methods. We will focus on the flange method, where a sheet metal. part is created in the formed state using specialized sheet metal features. To begin we first want to turn on the. Sheet Metal. tab on the .

A Shehab. 👕 Science Merch: https://my-store-d39398.creator-spring.com/ SOLIDWORKS 2024 For Beginners 👉 : https://amzn.to/3YMFHeG. 👉 https://amzn.to/3M85SVuIn .

To create a multibody sheet metal part: Create new bodies in an existing sheet metal part using Base Flange, Convert to Sheet Metal, Insert Bends, and Lofted-Bend commands. Split a .When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the .

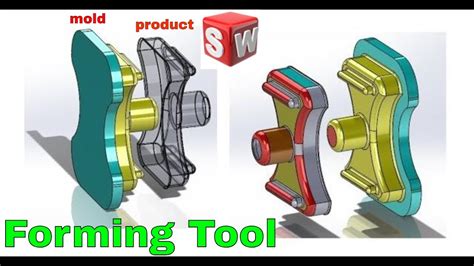

In the Insert Part PropertyManager:. Under Transfer, select Sheet metal information if you want to transfer the sheet metal and flat pattern information from the original part to the mirrored part, such as fixed face, grain direction, bend lines, and bounding box. You can also select Unlocked properties, which lets you edit the sheet metal definition in the mirrored part.A rip feature is commonly used to create sheet metal parts, but you can add a rip feature to any part. Adding Weld Beads to Sheet Metal Corners. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to .Using Sheet Metal Tools. Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in .For example, in sheet metal parts with up and down bend directions, you can map the different bend line directions to separate layers when you export the part. To export and map bend line directions for a sheet metal part: . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .

Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You can create a configuration in a sheet metal part that shows the flattened part. Looking to try SOLIDWORKS today? Access a free 7-day online trial that performs brilliantly on any computer with a steady internet connection.U.K. & Ireland .

solidworks sheet metal tools

Single open contours can be used for extrudes, revolves, sections, paths, guides, and sheet metal. Typical open contours are sketeched with lines or other sketch entities. Splines are invalid sketch entities for sheet metal parts with open contours.In the Insert Part PropertyManager:. Under Transfer, select Sheet metal information if you want to transfer the sheet metal and flat pattern information from the original part to the mirrored part, such as fixed face, grain direction, bend lines, and bounding box. You can also select Unlocked properties, which lets you edit the sheet metal definition in the mirrored part.Open the captured sheet metal part in SOLIDWORKS. Locate the Sheet-Metal feature in the SOLIDWORKS feature manager, right click > edit feature; Under Bend Allowance select "Bend Allowance" from the drop down, click OK to close the feature properties tab. Select the Sheet-Metal feature from the feature manager.What I do is check the "Override default parameters" on the sheet metal feature. Then, while in context of the assembly, I double click on the body. This will show your sheet metal dimensions (thickness, radius, and K factor for me). Then you can modify the thickness by double clicking it, and then link it to your assembly level custom property.

Creating Custom Operations for Sheet Metal Parts. You can create custom operations in the sheet metal template or in the CostingManager. Custom Operations PropertyManager. Use the Custom Operations PropertyManager to create custom operations to apply additional costs to parts. Applying Custom Operations in Sheet Metal Parts

Multibody part modelling is a very useful design method and can rapidly increase productivity. Often, designer don’t utilise this capability with Sheet metal. How to Prepare Rolled Sheet Metal Parts in SolidWorks. Let’s walk through the steps necessary to flatten a rolled sheet metal part in Solidworks to prepare it for laser cutting. Step 1: Use “Cut-Extrude” to make a parting line in your rolled part. First, open your transition part file and make a parting line which will be the seam when .Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal.; In the PropertyManager, under Sheet Metal Gauges, set options if you want to use a gauge table:. Select Use gauge table.; In Select Table, select a gauge table to use, or click Browse and browse to a gauge table.; Under Sheet Metal Parameters: . Select a face as the . The word "Advanced" can have so many meanings based on ones perspective. Someone who has never used SOLIDWORKS Sheet Metal may find the simple and awesome ab.

Step 2: Create Base flange: Select your sketch in the feature tree then in the command manager select the base flange function from the sheet metal tab.: Add a dimension to set the depth of your profile in this case 10mm: .You can create a multibody sheet metal part using any command that creates multiple bodies from a single body. Use these commands on the Features toolbar to split a sheet metal part into multiple bodies: . Search 'Splitting Sheet Metal .

You can create a multibody sheet metal part by creating new sheet metal parts within an existing sheet metal part. You can add new sheet metal bodies using these commands: Base Flange/Tab; Convert to Sheet Metal; . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. . In this lesson, you create the sheet metal part. This lesson demonstrates: 1.Creating a base flange 2.Adding a miter flange 3.Mirroring the part and creating.Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .

As a test, try to insert an axis on the conical face. If you can insert an axis, the model is an exact cone. If you cannot insert an axis, then the model is not an exact cone and cannot be unfolded. However, sheet metal parts created with the Lofted Bends .

Sheet Metal Design in SolidWorks for Beginners | Step-by-Step TutorialIn this comprehensive SolidWorks tutorial, we'll walk you through the fundamentals of s.

Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You can create a configuration in a sheet metal part that shows the flattened part. When it comes to creating a sheet metal part in SOLIDWORKS you have two choices for the first step: converting to sheet metal or building up from a base. Method 1 – Base Flange. For this option you start with the Sheet Metal option right away. First, you do a sketch and then define the sheet metal options like thickness and default bend radius.The sheet-metal module included in SolidWorks allows us to create different types of consumer products that are part of our daily lives. These products can be broken down into standard parts for mass production. One of the quickest ways to create a sheet-metal assembly is to use the function Convert to Sheet Metal from a Prismatic Volume’. Sheet Metal Gauge is a setting SOLIDWORKS parts are assigned as soon as the first sheet metal feature is created. It's easy to create and manage multiple variations of similar parts or assemblies using configurations. We frequently configure the values of dimensions, the suppression state of features, and part materials. Sheet metal parts are no different, and we .

using the SOLIDWORKS Sheet Metal functionality. The document provides a general description of the most common sheet metal “problems” . When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc.

Swiss turning is a specialized process for machining small, high-precision turned parts.We are able to ultra-precision machine extremely complex parts on 7-axis Swiss turning centers and maintain tolerances up to +/- 0.001.

how to create sheet metal parts in solidworks|solidworks convert to sheet metal