sheet metal forming process This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal .

For example, we needed to glue a piece of wood to metal that was going to hold over 100 pounds. We needed to find out the absolute best type of glue or adhesive to use to hold these 2 different materials together.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal operations with diagrams

4 · sheet metal forming process pdf

5 · sheet metal bending process pdf

6 · forming sheet metal by hand

7 · bulk deformation vs sheet metal forming

Metal boxes are required for proper grounding and bonding of your electrical system. Certain applications require specialized electrical boxes for safety and proper installation. Depending on where you’re installing an electrical box, you’ll need to use some different options.

Learn about sheet metal forming, a popular and useful manufacturing method that uses metal sheets to make various products and components. Explore the different processes, suitable materials, and pros and .Sheet metal forming is an effective means of producing sheet metal parts in complex three-dimensional shapes with a minimum of material. This conventional process involves a set of . Sheet metalworking, also known as Sheet metal forming and sheet metal fabrication, is a manufacturing process of cutting and forming relatively thin metal sheets, strips, and coils to create desired shape sheet .In this article, learn the basics of sheet metals, the various sheet metal forming processes, and how to reduce the cost of sheet metal forming with rapid tooling and 3D printed dies. For a detailed overview and the step-by-step method, .

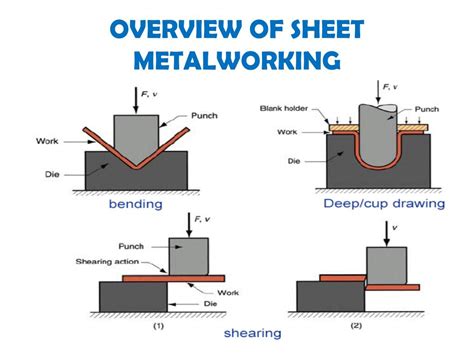

Metal forming processes Metal forming: Large set of manufacturing processes in which the material is deformed plastically to take the shape of the die geometry. The tools used for such deformation are called die, punch etc. depending on the type of process. Plastic deformation: Stresses beyond yield strength of the workpiece material is required.

This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal .

Sheet metal expanding is a specialized process within sheet metal forming that involves stretching the metal to create a mesh-like pattern. This technique enhances the flexibility and strength of the sheet metal, making it suitable for various applications, including filtration, screening, and architectural details.

From metal cans to protective housing for hardware, parts created by sheet metal forming are found everywhere in our daily lives. In this article, learn the basics of sheet metals, the various sheet metal forming processes, and how to reduce the cost of sheet metal forming with rapid tooling and 3D printed dies. Since the 1960s, numerical simulation has replicated the sheet metal forming process. The utilization of numerical simulation has grown progressively in examining intricate engineering obstacles. Researchers are investigating numerical analysis methods to address various problems associated with the sheet metal forming process.

Request PDF | On Nov 13, 2024, Bharat Bhushan and others published Numerical Modeling of Incremental Sheet Metal Forming Process for Generating Complex Shapes on Ti6Al4V | Find, read and cite all .%PDF-1.4 %âãÏÓ 663 0 obj > endobj 685 0 obj >/Filter/FlateDecode/ID[704E8A5A77AA90E0E45753C1AAABDACC>]/Index[663 39]/Info 662 0 R/Length 112/Prev 3172114/Root 664 .

Deep drawing is another widely used metal forming process. With a deep drawing, a metal sheet is clamped and placed over a cavity-shaped die. It is then punched down, which causes it to be “drawn” through the cavity — hence the name. The result is the metal sheet taking the shape of the die, which is usually cup- or box-shaped.

Sheet Metal Forming Processes; Power metal forming process; Bulk Forming Processes. Bulk forming process involves using raw materials with a low surface area to volume ratio for shaping. This category includes processes like rolling, forging, extrusion, and drawing. Different forces, such as compressive, tensile, shear, or a combination of .The forming of the sheet can be carried out using mechanical tools, with air or with liquids, magnetically or with explosives. Special sheet metal processes include superplastic forming and press hardening, as well as the hot forming of aluminum and magnesium. Table 1 shows the common characteristics of sheet metal forming processes.INTRODUCTION TO SHEET METAL FORMING PROCESSES - SimTech . simulation

In this video we will discuss three basics to sheet metal forming. For more information visit www.rapidmanufacturing.comSheet Metal Forming Simulation. Kuang-Hua Chang, in Product Manufacturing and Cost Estimating Using Cad/Cae, 2013. 4.2.1 Sheet Forming Processes. In a sheet forming process, a thin piece of metal sheet, commonly referred to as the blank, is bent or stretched by tools into a desired shape without excessive thinning, tearing, or wrinkling.Here we present a brief . #2. Sheet metal forming. Sheet metal forming involves the application of tensile and shears forces to fabricate sheets, plates, and strips to a desired possible shape using a set of tools. The punch and die are used as tools in the fabrication process.

What Is Sheet Metal Forming? Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products . Giuliano G, Polini W. Influence of blank variable thickness on the material formability in hot gas sheet metal forming process. Manuf Lett 2020; 24: 72–76. Crossref. Google Scholar. 62. Kim YH, Lee J-M, Hong SS. Optimal design of superplastic forming processes. J Mater Proc Techn 2001; 112: 166–173. Crossref. Numerical simulation of metal forming processes, as a component of the virtual manufacturing process, has a very important contribution to the reduction of the lead time. The nite element method is currently the most widely used numerical procedure for s- ulating sheet metal forming processes.Sheet Metal Forming Process Chain Overview AutoForm’s state-of-the-art technology covers the process chain and brings together all the important aspects of sheet metal forming. Our portfolio of software products enables you to address complex issues that arise in practice and to achieve a new level of competitiveness.

The fracture’s forming load, stroke, and position were determined for different working temperatures of the sheet metal forming process for AZ31, using a finite element simulation combined with .This chapter provides an introduction to metal forming processes and where they fit among the five general areas of manufacturing. It also discusses the basic differences between bulk deformation and sheet-metal forming processes and how they relate to hybrid forming processes such as drawing, bending, and coining.Sheet-Metal Forming Processes Process Roll forming Stretch forming Drawing Stamping Rubber-pad forming Spinning Superplastic forming Peen forming Explosive forming Magnetic-pulse forming Characteristics Long parts with constant complex cross-sections; good surface finish; high production rates; high tooling costs.After the precise cutting of metal sheets, the subsequent stage in sheet metal fabrication is the forming and shaping process. This phase is essential for giving the flat metal pieces their desired three-dimensional form.

86 8 Sheet Metal Forming Processes with the selection of stock width is done. This calls for several trial layouts. If A b represents the area of blanks produced in one press stroke and A s the strip area consumed by one press stoke or strip width times feed length, then theIntroduction. Bulk deformation and sheet metal forming are two common manufacturing processes used to shape metals into desired forms. While both methods involve the deformation of metal, they differ in terms of the starting material, the types of products produced, and the specific techniques employed.

FIGURE 29 Schematic illustration of a stretch-forming process. Aluminum skins for aircraft can be made by this method. FIGURE 30 The metal-forming processes involved in manufacturing a two-piece aluminum beverage can. FIGURE 31 (a) Schematic illustration of the deep-drawing process on a circular sheet metal blank. The stripper ring facilitates .

Incremental sheet metal forming (ISMF) is commonly regarded as a die-less sheet metal forming process which can form complex three-dimensional parts using relatively simple tools. It is receiving attention from the engineering community due to its flexibility and low cost. This unique combination enables the rapid prototyping of functional .The forming analysis system ARGUS supports the optimization of the sheet metal forming process. For the automatic optical forming analysis, sheet metal blanks are marked with a regular dot pattern with 1 mm, 2 mm or 3 mm distance in between the dots, depending on the shape and radians of the part. After forming, the sheet metal component is .

3 4-inch deep electrical box

Asphalt and Copper Metal Roof Color Combination in a Stained Clapboard Siding House. This is an example of a large contemporary house. The roof is asphalt shingles from GAF in Pewter weathered gray color. Why gray? It is because black shingles roof .

sheet metal forming process|sheet metal operations with diagrams