how is sheet metal thickness measured Yes, sheet metal thickness is important as it determines what kind of fabrication processes can be used. Thinner sheet metal is suitable for different processes and different . See more CNC turning centers are essential for precision machining, offering high accuracy and efficiency in producing cylindrical parts. Understanding the components, operation, and capabilities of CNC turning centers is crucial for optimizing their use in manufacturing.

0 · which thickness called sheet metal

1 · sheet metal thickness chart wikipedia

2 · sheet metal thickness by gauge

3 · sheet metal gages vs thousands

4 · metric sheet metal thickness chart

5 · gauge vs thickness chart

6 · base metal thickness chart

7 · 10 gauge thickness in inches

$51.57

Standard sheet metal thickness and size varies across different metals. Find standard sheet metal gauges and mm measurements in this article. See moreIn Australia, the typical thickness of sheet metal is between 0.5 millimetres and 6 millimetres. Anything thicker 6 millimetres is classified as metal plate, and anything thinner than 0.5 . See moreIn the fabrication industry, ‘gauge’ is an identifier for the standard thickness of sheet metal of a specific material. The gauge size is based on the weight of the metal sheet and is inversely proportional to the thickness, which means the higher it is, the thinner the . See moreThere are two ways to measure sheet metal: using a measuring tape (which is less precise) and a gauge wheel (more typically used in the industry). See more

Yes, sheet metal thickness is important as it determines what kind of fabrication processes can be used. Thinner sheet metal is suitable for different processes and different . See more The chart below can be used to determine the equivalent sheet thickness, in inches .

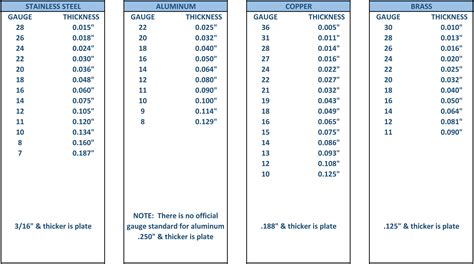

Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool . Sheet metal gauge is a fundamental measurement in metalworking that denotes the thickness of sheet metal. Originating from the Browne & Sharpe system in North America, gauge is a standardized unit used to specify the .

sheet metal shearing machine parts

When you need to know the thickness of your metal, a steel gauge chart is your guide. The numbers of a steel gauge chart typically range between 3-30. Yet those numbers do not indicate a specific dimensional value. Both gauge thickness and measured thickness convey a standardized measurement describing sheet metal, but just with different numbers and bases of measurement. With metric, the base measurement is 10, i.e. 10 . How Do Sheet Metal Gauges Work? Unlike standard or metric measurements, which rely on units like inches or millimeters, gauging follows its own set of rules. To find out . A sheet metal gauge is a standard unit of measure used to determine the thickness of a metal sheet. The gauge number and thickness have an inverse relationship – the higher .

How to read a steel gauge thickness chart. There two primary principles to keep in mind when using steel gauge charts: Moving up or down a given steel gauge chart isn’t an . A metal’s gauge refers to its thickness, which greatly affects its resistance. When figuring out a metal’s thickness, keep the following facts in mind: Sheet gauges start at .010” and go up to .170” (or 7 gauge) Gauges are used to specify the thickness of a sheet metal. Gauges are neither standard nor metric and the values are independent of those measurement systems. A gauge conversion chart can be used to determine . The concept of ‘gauge’ refers to the standard measurement used to quantify the thickness of sheet metal; however, it can be somewhat confusing as lower gauge numbers indicate thicker materials while higher numbers denote thinner ones. . This inverse relationship between gauge number and actual measurement can vary slightly depending on .

In simple terms, gauge refers to the thickness of a piece of sheet metal or wire. The higher the gauge number, the thinner the material, and vice versa. Different industries use different measurement systems for gauging steel, such as the Birmingham Gauge (BG), Standard Wire Gauge (SWG), and American Wire Gauge (AWG).

Gauge System: How the Thickness of Metal Roof is Measured. The gauge system is a common method for measuring the thickness of metal roofs. This system originated from the wire industry and has been adopted for metal roofing and other sheet metal applications. As mentioned earlier, the lower the gauge number, the thicker the metal sheet. .

Sheet gauges are sold according to gauge or decimal equivalent. They normally require a caliper to determine thickness. . Fit the two tips of the calliper around the metal you need and you can accurately measure the thickness. This is a useful method when replacing an existing piece when you know the new sheet of aluminum will have to be .Discover the importance of steel gauge charts and how to use them effectively.Content blocked Please turn off your ad blocker. When selecting a tool for measuring the thickness of metal sheets, you should consider the range of thicknesses, the shape and size of the sheet, the surface condition and texture of the metal .

Step 2: Measure Expanded Metal Thickness. Using a caliper, measure the thickness of the expanded metal sheet or panel. This will help you determine the gauge or wire diameter of the material. Expanded metal is defined by its mesh size, which refers to the distance between two adjacent strands. Measure the mesh size using a ruler or tape measure.

Learn how to measure stamped sheet metal thickness with MTI’s Digital Accumeasure, a high-precision capacitance measurement system with nanometer accuracy and stability.. Problem. High silicon steels are alloys of iron and silicon that are easily magnetized and demagnetized. They can be supplied as sheet metal with a very thin dielectric coating. What is Stainless Steel Sheet Metal Thickness? Definition and Importance; Stainless steel sheet metal thickness refers to the distance between the two surfaces of the sheet. This measurement is critical because it directly impacts the material’s strength, flexibility, and suitability for different applications.A student measured the thickness of a metal sheet using a screw gauge with least count 0.001 cm and listed the measurements. The correct measurement is - (1) 4.2 cm (2) 4.22 cm (3) 4.220 cm (4) 4.2200 cm 88. One full rotation of the cap of a screw gauge is equivalent to 5 mm. The cap has 100 division.

The gauge of a sheet of metal is a reference to how thick it is. The higher the numbered gauge a piece of metal is, the thicker the piece is in millimeters. If you want to find out what gauge your sheet metal is, measure its thickness using a regular tape measure.

A gauge is a traditional, non-linear measurement. The most commonly used sheet metal sizes range from 30 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness, and . Have you ever wondered why carpenters get to work with 1/2″ drywall but metal fabricators have to specify sheet metal thickness in terms of gauge? . And if that weren’t enough, the actual measured thickness for a .

Metal gage is not a preferred method to specify thickness, even though it is commonly listed. The thickness associated with a particular gage value changes with the material specified. 22ga aluminum is not the same .Titanium sheet dimension range is from a thickness as low as 0.3 mm and lengths up to 5600 mm by width of 2800 mm. Contact us now for the latest in titanium sheet prices and availability. Having invested significantly in advanced titanium sheet metal rolling equipment the machine inventory includes best in class rolling equipment. You can also use a thimble to measure the thickness of sheet metal parts. This will help you find out how thick or thin the part is. You should take note of the distance between the tabs and the bend so that they don’t distort the sheet metal. If you don’t follow these rules, the part might become inaccurate.

STK: A measurement of starting raw material thickness. Contrary to belief, the expanding process does not directly alter material thickness. Strand Thickness should not be confused with the overall height or depth of expanded metal. Typically, mesh height can be as much as 1-2 times the measurement of SWDT. How to Measure a Flattened Mesh

4 Precision Sheet Metal Size FAQ. 4.0.1 What factors should I consider when choosing the right sheet metal gauge for my project? 4.0.2 How can I ensure I'm using the right material thickness for my sheet metal project? 4.0.3 Can you share a real-life example of how choosing the right sheet metal gauge made a significant difference in a project?

When purchasing sheet metal, the thickness is typically measured via the gauge system. Meanwhile, the Brown and Sharpe Gauge is used to measure brass, aluminum, and other non-ferrous metals. How strong is 2mm thick Aluminium?

Sheet metal gauge, often simply referred to as ‘gauge’, is a measure of the thickness of a metal sheet. It is a numerical value assigned to sheet metal, and the gauge is inversely proportional to the thickness, where a higher gauge number corresponds to a thinner sheet. This means that a 12-gauge sheet metal is thicker than a 16-gauge sheet . A 0-gauge sheet metal screw is 0.06 inches in diameter, whereas a 14-gauge sheet metal screw is .24 inches in diameter. The higher the gauge, the wider the sheet metal screw. Length Moving up to a 16-gauge stainless steel sheet, the decimal equivalent is 0.0595; The decimal equivalent of gauge numbers differs based on type of metal. Again, let’s use stainless steel as our example: A 14-gauge stainless steel sheet has a decimal equivalent of .0751. A 14-gauge carbon sheet has a decimal equivalent of 0.747.

How are metal roofing materials measured? What are gauges?Comment with your question to have it answered in a future episode!*****. To provide metalformers with a reliable and dependable process to instantly and accurately measure lubricant thickness, and to determine its distribution across the complete coil or sheet surface, Amepa GmbH (Amepa America Inc., Middleburg Heights, OH) has introduced an oil-film measurement (OFM) system.

which thickness called sheet metal

Purchase a metal print of the photograph "Brooklyn Bridge, Twin Towers, Nyc, Ny" by Barry Winiker. All metal prints are professionally printed, packaged, and shipped within 3 - 4 business days and delivered ready-to-hang on your wall. Choose from multiple sizes and mounting options.

how is sheet metal thickness measured|sheet metal thickness by gauge