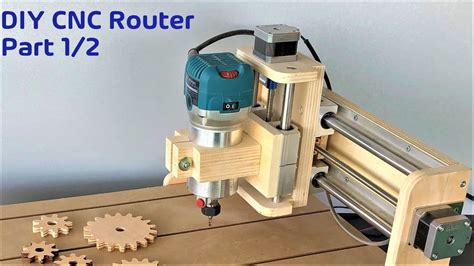

how to build your own cnc machine part 2 DIY CNC Router/Machine: How to Build Your Own. by Andreas Giencke. Updated Feb 6, 2023. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to . Featuring a combination lock for top notch security, and 4 universal wheels to be able to take it with you wherever you please. It accommodates a foolscap size file vertically, and A4/ Letter size file laterally. Keys not included. Includes 1 pencil tray and one hanging bar as additional features.

0 · homemade cnc router machine

1 · homemade cnc milling machine plans

2 · homemade cnc machine plans

3 · homemade cnc machine

4 · home built cnc milling machine

5 · do it yourself cnc machine

6 · diy cnc machine for woodworking

7 · build it yourself cnc router

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve.

homemade cnc router machine

Build Your Own CNC! (Part 2) - Inputs, Outputs & Software. Follow-up to Part 1. Inputs, Outputs and software configuration. (Mach 4)Part 1 of this video: https://youtu.be/K0XfRPi_h2MMy. In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural .

To build the mechanical base of the machine, it's important to put in some design time. Determine how much material you have, draw out your design and estimate how much .

32 amp junction box b&

In this video, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are . DIY CNC Router/Machine: How to Build Your Own. by Andreas Giencke. Updated Feb 6, 2023. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to . 2. What skills should I have to build a CNC machine? Building your own CNC machine can be hard, but it can be easy if you have the necessary skills. If you are experienced in metalworking or woodworking, it is much .These comprehensive guides enable enthusiasts and professionals alike to build their own CNC and laser machines. From large wooden CNCs to versatile combo CNC and laser machines, and robust all-metal designs, our plans cater to a .

To begin our journey, we will provide a comprehensive overview of CNC machines. From their history to their various applications, we will explore the basics of how these machines work and the benefits they offer. 2. Designing Your DIY CNC Machine:\ Building a CNC machine requires careful planning and design.Teaches you to design and mill your very own wooden and aluminum parts, toys, gadgets—whatever you can dream up ; Similar content being viewed by others. . including LEGO robotics, open source software, and building your own CNC machine as well as a 3D printer. He is the editor-in-chief of the number one MINDSTORMS NXT blog, The NXT Step .

Build your own DIY CNC router kits 10. MPCNC – Mostly Printed CNC Machine Kit. Cost to build: . If you 3D print the parts yourself the cost runs into around 8, and over 0 if you buy the printed parts. . How much time do you feel you can dedicate to building your machine (to decide whether to buy an easier kit or build from scratch . Cautions. Whether you are building an affordable CNC router, or making the best budget CNC lathe machine, even working with DIY the cheapest CNC milling machine, the first caution is the power supply of the CNC machine.There are three stepping motors and one spindle motor on the machine. Therefore, the current of the CNC machine is very large in the process .

Follow-up to Part 1. Inputs, Outputs and software configuration. (Mach 4)Part 1 of this video: https://youtu.be/K0XfRPi_h2MMy CNC Basics Video: https://yout. Description and CNC defined including the some history. This also might be a good place for the various types of CNC machines.- Chapter 2 DIY-CNC Project Overview Description of the project, tools required and safety. Will include computer requirements.- Chapter 3 Cutting the parts describes the parts layout and special instructions for cutting.- Then they go on to show you how to use it, how to document your designs in computer-aided design (CAD) programs, and how to output your designs as specifications and tool paths that feed into the CNC machine, controlling it as it builds whatever parts your imagination can dream up.Don't be intimidated by abbreviations like CNC and terms like . Building your own CNC machine can be an exciting and rewarding project. With the right knowledge and resources, you can create a customized CNC machine right in your own home. . Purchase the necessary parts and tools for your DIY CNC machine. This may include stepper motors, linear slides, spindle, controller board, and other components. Make .

5. What skill sets should you have to build a CNC machine? It’s easier to build your own CNC machine if you already have some of the necessary skills. As such, aim to complete a project that plays to your experience. If you’re already experienced in woodworking or metalworking, then you may wish to try out a more challenging project.Resin Printer Parts Stepper Motors CNC Controllers Motion Electronics Wire and Cable . CNC Book "Build Your Own CNC Machine" The book on how to build yourself a CNC machine from the ground-up, is available. The book was authored by James Floyd Kelly (a great friend and writer of many tech books) and Patrick Hood-Daniel (the author of this .

In this blog post, we will guide you through the step-by-step process of building your own CNC machine, from sourcing materials to programming the machine. Chapter 1: Understanding CNC Machines . Introduction to CNC machines . Advantages of building a DIY CNC machine . Basic components of a CNC machine . Chapter 2: Planning and Design

A podcast from Make: founder, Dale Dougherty. Shop. Kits, Books, & More. Maker Shed, the official store of Make: Make: Magazine. Subscribe to the premier DIY magazine today. New. Makerspace Directory. A comprehensive community driven directory

Assemble the parts carefully, following the manufacturer's instructions, and enjoy the satisfaction of watching your DIY CNC machine come to life. Remember, building a CNC machine requires patience, precision, and attention to detail. It's a challenging but rewarding project that allows you to unlock a world of possibilities in your own . Find out more about CNC router parts and get some guidance to join the fun. All3DP; All3DP Pro; Printables Basics Buyer's Guides News Formnext 2024. More . Printables; . DIY CNC Router: Which Parts Do You .The 8020 CNC machine is a type of CNC router that uses extruded aluminum profiles from a company called 80/20 Inc. This company specializes in providing modular framing systems that can be used to build anything from basic workbenches to complete automation systems. To build your own 8020 CNC machine, you'll need to start with the right components.I've built 2 machines in that sort of budget. The first thing I'd say is that if your time is worth anything and your only goal is to have a working machine, just buy one. That said, I build because I enjoy it. To me the build process is part of the hobby. .

Free Book Build Your Own CNC Machine First Edition By Patrick Hood-Daniel and James Floyd Kelly pdf. . Do you want to manufacture your parts? Build Your Own CNC Machine is a book to start with. Patrick Hood Daniel, a CNC expert and best-selling author, James Kelly, collaborates to illustrate how to create your own CNC machine. . Dive into the world of CNC and transform your ideas into reality with precision and efficiency. Start building your own CNC machine today and unlock limitless creative potential. 1. Introduction to CNC Machines. What is CNC? CNC stands for Computer Numerical Control, a technology used to automate the control of machine tools.Get full access to Build Your Own CNC Machine and 60K+ other titles, with a free 10-day trial of O'Reilly. There are also live events, courses curated by job role, and more. Start your free trial. . controlling it as it builds whatever parts your imagination can dream up.

You probably won’t believe this, but the CNC machine described in this book can be built with a total of four tools (mitre box, mitre saw, tap, and electric drill/screwdriver) and a few .By constantly exploring new features and techniques, your CNC machine can evolve along with your skills and project requirements. 7. Conclusion . Building your own CNC machine is a challenging but rewarding endeavor. With the right CNC kit and proper guidance, you can bring your creative ideas to life with precision and accuracy.

We'll cover topics such as machine size, frame materials, overall stability, and dust collection setup. By the end of this section, you'll have a clear understanding of how to design your CNC machine to suit your specific woodworking needs. Section 4: Assembling the CNC Machine . Now, it's time to roll up your sleeves and start assembling your .greenBull v2 Plans option. The plans option includes a large set of 24"x36" plans which includes the BOM (Bill of Materials) for the complete machine, 1:1 scaled drawings of all of the structural components that will need to be cut out or fabricated, and a full set of detailed instructions for assemblling the machine.

Elevate your woodworking and crafting capabilities with our top-tier DIY CNC Router Plans for the greenLean v2. Designed specifically for enthusiasts and professionals who are tight on space, these detailed 24"x36" digital plans are a must-have for anyone looking to build their own large-format, vertical CNC machine. Perfect for creating custom cabinets, intricate signs, and unique .

30x50 metal house

$20.00

how to build your own cnc machine part 2|build it yourself cnc router