5 axis high speed cnc machining The Haas UMC Series universal machining centers are cost-effective solutions for . The drill bit size chart provides equivalent sizes for letter, metric, wire gauge, and fractional drill bit sizes, allowing the user to select the correct drill bit for their project.

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

Drywall screws are most often used with soft woods such as pine and spruce, and they can also be used to attach metal or plastic wall panels to wood studs. Decking screws are generally more suitable for unpainted hardwoods like oak, as they are strong and have more holding power.

The GM-2-5AX and HDC-3-5AX are cost-effective solutions for simultaneous 5-axis machining and 3+2 machining of very large parts, such as airframe components, layup molds, and .The Haas UMC Series universal machining centers are cost-effective solutions for .The EC-1600ZT-5AX has a 4th-axis rotary platter integrated into the T-slot table .With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis .

The GM-2-5AX and HDC-3-5AX are cost-effective solutions for simultaneous 5-axis machining and 3+2 machining of very large parts, such as airframe components, layup molds, and composite structures. The flexibility of the 2-axis spindle head provides access to nearly any angle for complex machining.With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis simultaneous milling of .

In selecting a 5-axis CNC machine, spindle speed is one of the parameters that deal with machining efficiency and surface finish quality. The increase in spindle speed leads to faster cuts, dramatically reducing the cycle time in processes requiring high speed. . They have been fitted with high-speed spindles capable of fast material removal .The Takumi U800 is a 5-axis, high-speed, CNC machining center that produces outstanding surface finish and is great for aerospace and automotive industries.

4 sheet metal

The Haas UMC Series universal machining centers are cost-effective solutions for 3+2 machining and simultaneous 5-axis machining. The UMC-750 has an integrated dual-axis trunnion table with a 500 mm diameter platter that features standard T .

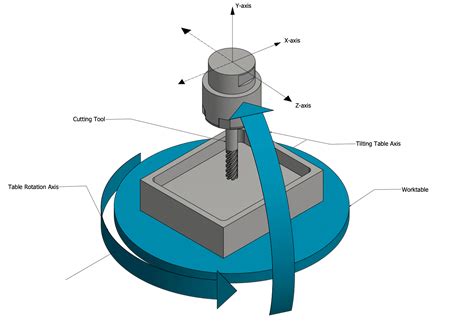

FANUC 5 axis CNC machining solutions are the most reliable 5th axis CNCs in the industry, including solutions for 5 axis CNC mill, 5 axis CNC machine & more.5-axis CNC machining involves simultaneous movement along five axes—three linear (X, Y, Z) and two rotational. This capability allows for the creation of complex parts in a single setup, significantly enhancing precision and efficiency.High-Speed Machining: Equipped with a high-speed spindle of up to 30,000 RPM, the U5 ensures fast and efficient cutting. This feature reduces machining time and increases productivity, making it ideal for high-volume production.

Experience the advantages of 5-axis CNC machining services at Advance CNC. Our cutting-edge capabilities enable complex geometries and efficient production. Request A Quote

Discover the benefits of 5-axis CNC machining in precision manufacturing. From enhanced accuracy to faster production and optimized tooling, learn how 5-axis technology is transforming aerospace, medical, and automotive industries with complex geometries and high-quality finishes. Explore why investing in 5-axis machines could elevate your manufacturing .The GM-2-5AX and HDC-3-5AX are cost-effective solutions for simultaneous 5-axis machining and 3+2 machining of very large parts, such as airframe components, layup molds, and composite structures. The flexibility of the 2-axis spindle head provides access to nearly any angle for complex machining.With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis simultaneous milling of .

In selecting a 5-axis CNC machine, spindle speed is one of the parameters that deal with machining efficiency and surface finish quality. The increase in spindle speed leads to faster cuts, dramatically reducing the cycle time in processes requiring high speed. . They have been fitted with high-speed spindles capable of fast material removal .The Takumi U800 is a 5-axis, high-speed, CNC machining center that produces outstanding surface finish and is great for aerospace and automotive industries.The Haas UMC Series universal machining centers are cost-effective solutions for 3+2 machining and simultaneous 5-axis machining. The UMC-750 has an integrated dual-axis trunnion table with a 500 mm diameter platter that features standard T .

FANUC 5 axis CNC machining solutions are the most reliable 5th axis CNCs in the industry, including solutions for 5 axis CNC mill, 5 axis CNC machine & more.

5-axis CNC machining involves simultaneous movement along five axes—three linear (X, Y, Z) and two rotational. This capability allows for the creation of complex parts in a single setup, significantly enhancing precision and efficiency.High-Speed Machining: Equipped with a high-speed spindle of up to 30,000 RPM, the U5 ensures fast and efficient cutting. This feature reduces machining time and increases productivity, making it ideal for high-volume production.

Experience the advantages of 5-axis CNC machining services at Advance CNC. Our cutting-edge capabilities enable complex geometries and efficient production. Request A Quote

what is 5 axis milling

4 weather proof junction box specifications

what does 5 axis mean

small 5 axis cnc mill

Where are CRAFTSMAN metal chests and cabinets made? CRAFTSMAN metal chests and cabinets are proudly made in Sedalia, MO with global materials. What is a soft close slide?

5 axis high speed cnc machining|what is 5 axis milling