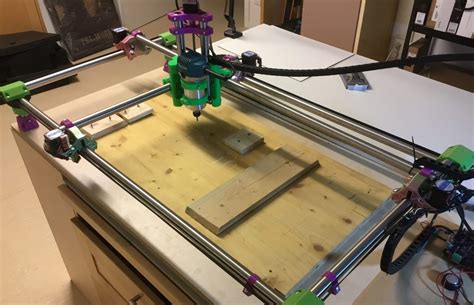

cnc router build part 1 A quick introduction the CNC router project I have started. When finished, I'll be using it to cut precise parts for a number of future planned projects. The. Interested in knowing about the different types of sheet metals and their uses? Get ready to gain all the required information on the topic with our complete guide.

0 · make your own cnc machine

1 · homemade cnc router plans

2 · homemade cnc router machine

3 · cnc homemade router

4 · building your own cnc

5 · build your own cnc router

6 · build your own cnc kit

7 · best cnc router for beginners

A junction box – also known as an ‘electrical box’, ‘jbox’, ‘or ‘terminal box’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete.Electrical boxes encase wire connections to protect them from short circuits. They are vital for fire safety and are used for receptacles, ceiling fans, outside outlets, and more. Unless the device is one of the few that contains its own wires, it likely will need an electrical box.

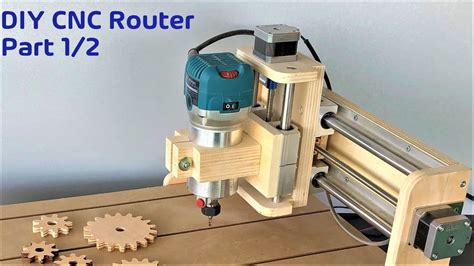

Build a CNC Router From Scratch (Part 1): Complete Video Tutorial: Completely build a CNC router from the ground up without plans, just your hands, some . Making a CNC Router - Part 1. TAOW. 261K subscribers. 5.8K. 332K views 4 years ago. This video is part 1 in a 4 part series on building a new CNC Router. This video covers the design and. Part 1 of CNC router assembly. This kit is from cncconversionkit.com. Extrusions - 60mm Ball screws - 15mm - 5mm pitch Rails - 20mm Carraige plates - 3/4" thick Z axis plates - 1/2". A quick introduction the CNC router project I have started. When finished, I'll be using it to cut precise parts for a number of future planned projects. The.

How to Build Your Own CNC Router Controller Box - Part 1CNC Router Build. In Part 1 I show you how to use an ATX Power Supply to control your homemade CBC co. In this video I take you through the building of my new Ooznest CNC router which has a 1500mm x 1500mm bed.This is part 1 of the video where I assembly the f.

This is the first part of the electrical element of my CNC build. An unregulated linear power supply consisting of a toroidal transformer, bridge rectifier a.Part 1 of CNC router assembly. This kit is from cncconversionkit.com. 173 . . CNC Router build part 1. 88. mahdi 96 دنبال کننده 88 بازدید .

DIY CNC Milling machine build.My objective for this project is to design and build a CNC milling machine without the need for any machining of the parts. Ord. A Roger b CNC Router Build Video 826 QueenAnt PRO V2 Super Enhanced CNC Router Chasse buildThank you for watching Help support my channel and become a Pa. Building of my CNC router, this is Part 1 which covers the design and building of the base

This a brief (long winded) description of the plan to build a 4x8 all steel CNC router. Please make suggestions in the comments! This is a longer term project to build myself a new CNC Router. It will have a cutting envelope of 36"x36"x12" and the gantry height reconfigurable for extra.This is the first video in my DIY CNC Router series. In this video I start building the frame of the CNC Router. ️ All of the videos in this series can be v.

For some time now, far too long really, we have discussed building a CNC router so that we can expand our abilities from only metal, to plastic, wood, carbon fiber, and machining aluminum. Well, we finally took the plunge! If you read the blog on our first plasma cutter, we used a Gecko G540 to update the machine to run after our HobbyCNC board burned up. We figured we . Hi, in the following two videos I documented the build of my DIY CNC machine. It's a 3-axis router with a wooden frame. Part 1 of the video shows the build of the frame while part 2 shows in detail how all the electronic components are connected. Also in part 2, there's a quick overview of the software and firmware that I use to run the machine .

In this video, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are .

PART 1 . Assembling the CNC milling machineЧАСТЬ 1 . Сборка фрезерного станок с ЧПУ Build instructions for an offline CNC controller based on the 4 axis DDCS V3.1 controller, part 2. Wiring diagrams and parameter settings for the controller . Part 1 in a series on building a CNC router.This episode covers the components which will be used and a brief overview of how they will work.Other videos in .

make your own cnc machine

A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances. Accessories include a 3D printed dust shoe, a complete spoilboard and hold down system, an XYZ touch probe .

Tips and Techniques: Gain valuable insights and tips from experienced operators to enhance your own CNC projects. Each video is a testament to the quality and innovation embedded in our CNC machines. Watch and be inspired to unleash your creative potential with the power of CNC machining. Making an Dust Shoe from 1/2" Acrylic using the .Part 1 of CNC router assembly. This kit is from cncconversionkit.com.Extrusions - 60mmBall screws - 15mm - 5mm pitchRails - 20mmCarraige plates - 3/4" thick.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

A Roger C b CNC Router build tutorial Episode 1 MIDI CNC RouterThank you for watching I need your help to keep making good contentPlease support my channe.

Hello friends, in this video series i'll be making a small benchtop CNC router for hobby works. You will find all the measurements and material names at the .I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm.Part 1 of CNC router assembly. This kit is from cncconversionkit.com.Extrusions - 60mmBall screws - 15mm - 5mm pitchRails - 20mmCarraige plates - 3/4" thick.With 8" of clearance this modification can be adapted easily to your existing LEAD CNC Router. . This OpenBuilds Mini Mill is a great go-to desktop sized CNC milling plate / part maker and 3D carving machine! . Build it - Share it! Collaborate on our forums and be sure to visit the Part Store for all your Maker needs.

CNC Router Build Video Workbee Kit 1500mm X 1500mmMusic used Morning Walk by Jonny Easton Link: https://youtu.be/LHFXQ7Y2cos Check out his channel Link: http.

homemade cnc router plans

$59.00

cnc router build part 1|build your own cnc router