conductors in junctions box The National Electrical Code has published a chart that determines a junction box’s correct size, based on the number and size of the conductors it must accommodate. The size of a conductor is expressed as AWG (American Wire Gauge); the .

Manually operate equipment to weld material used in transformer manufacturing. Use engineering drawings to fabricate and weld product ensuring the highest. More. One or more years of welding and fabrication experience. Freight Car Repairers will complete 1 week of Mechanical Safety Orientation and 6 weeks of craft. More.

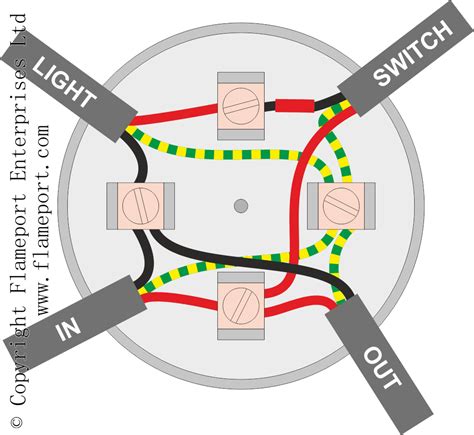

0 · wiring junction box for lighting

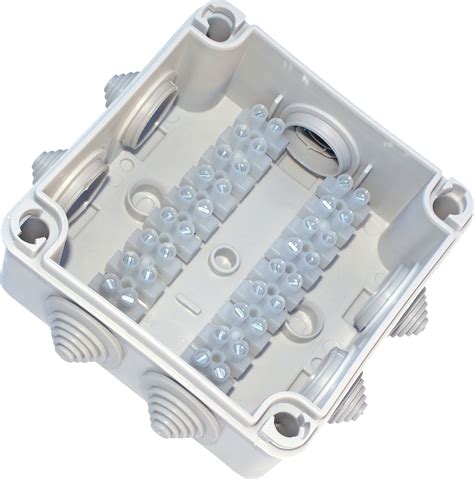

1 · mains junction boxes with terminals

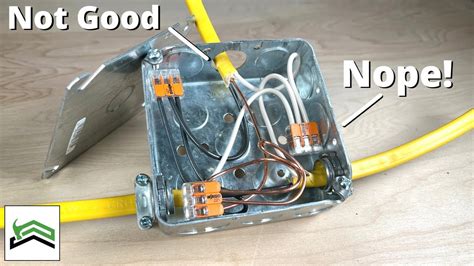

2 · junction box wiring problems

3 · junction box wiring identification

4 · junction box wiring guidelines

5 · junction box for electrical wiring

6 · electrical junction box wiring diagram

7 · connecting wires in junction box

The Husky Welded Garage Cabinets are built tough for any project. They're made with durable 24-Gauge steel and come with Husky's Lifetime Warranty, so you know they're built to last. The cabinets come pre-assembled and ready to .

Box Fill Guidelines: No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is counted as one wire. Each wire .

When devices are mounted in the box, the total conductor count must be increased by two for each mounting strap (not to be confused with ground wires). To put it simply, each current-carrying conductor (hot, neutral) . Use this guide to learn how to count wires in an electrical box to ensure your electrical upgrade is safe and successful. The volume of an electrical box determines the number and size of conductors and wiring devices that can be contained within the box.Box Fill Guidelines: No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is counted as one wire. Each wire connecting to a device counts as one wire of that size. When devices are mounted in the box, the total conductor count must be increased by two for each mounting strap (not to be confused with ground wires). To put it simply, each current-carrying conductor (hot, neutral) that enters the box, counts as one box fill unit.

The National Electrical Code has published a chart that determines a junction box’s correct size, based on the number and size of the conductors it must accommodate. The size of a conductor is expressed as AWG (American Wire Gauge); the . Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®.

Part (B), “Box Fill Calculations,” describes the method for determining how much volume (fill) may be occupied by conductors, clamps, support fittings, devices (switches or receptacles) or equipment, and equipment grounding conductors. Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box.

In a junction box that’s too small, an electrician may have to bend conductors excessively to fit them fully inside the box, which risks damaging the insulation on the wires. Conductors and other components spaced too closely may also create interference or .

Choose a junction box with conductor fill volume (which is the number of conductors allowed in a junction box) higher or equal to the number of wires (after multiplying them by 2 and adding in the ground wire) entering the junction box. Installing an electrical junction box gives you freedom and flexibility when installing electrical cables. It's often used when an electrical circuit branches off in two or more directions. Use this guide to learn how to count wires in an electrical box to ensure your electrical upgrade is safe and successful. The volume of an electrical box determines the number and size of conductors and wiring devices that can be contained within the box.

Box Fill Guidelines: No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is counted as one wire. Each wire connecting to a device counts as one wire of that size. When devices are mounted in the box, the total conductor count must be increased by two for each mounting strap (not to be confused with ground wires). To put it simply, each current-carrying conductor (hot, neutral) that enters the box, counts as one box fill unit. The National Electrical Code has published a chart that determines a junction box’s correct size, based on the number and size of the conductors it must accommodate. The size of a conductor is expressed as AWG (American Wire Gauge); the . Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®.

Part (B), “Box Fill Calculations,” describes the method for determining how much volume (fill) may be occupied by conductors, clamps, support fittings, devices (switches or receptacles) or equipment, and equipment grounding conductors. Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box. In a junction box that’s too small, an electrician may have to bend conductors excessively to fit them fully inside the box, which risks damaging the insulation on the wires. Conductors and other components spaced too closely may also create interference or . Choose a junction box with conductor fill volume (which is the number of conductors allowed in a junction box) higher or equal to the number of wires (after multiplying them by 2 and adding in the ground wire) entering the junction box.

wiring junction box for lighting

electrical box cover plates extention

Spot welding is a process that uses electricity to join two pieces of metal together. It’s a popular choice for joining sheet metal because it’s relatively quick and easy to do and creates strong bonds with minimal distortion.

conductors in junctions box|wiring junction box for lighting