injection moulding cnc machines Injection Molding and CNC Machining, while seemingly similar, operate on fundamentally different principles. Injection Molding, akin to casting, molds molten materials into predefined shapes. CNC Machining, in contrast, . At Smartlathe CNC, we pride ourselves on being a leading supplier of reliable, stable, and cost-effective CNC lathes. Beyond providing high-quality machines, we also offer comprehensive .

0 · top 10 injection molding machines

1 · injection moulding machines full details

2 · injection moulding machine types

3 · injection moulding machine manufacturers

4 · injection moulding machine full explanation

5 · injection moulding machine diagram

6 · injection molding machine price list

7 · high precision injection molding machine

The TRYAX TY series is ushering in a new era for diamond cut alloy wheels. These CNC vertical alloy wheel lathes are characterised by their innovative purpose built design. Built from the ground up both mechanically and electrically the systems offer an easy to use touchscreen interface coupled with the latest state of the art real-time control .

top 10 injection molding machines

FANUC ROBOSHOT takes state-of-the-art CNC precision technology from CNC turning and CNC milling and applies it to electric injection molding. The results are greater acceleration, ultimate precision of movement and extremely short .Discover cutting-edge features like the powerful CNC control and intuitive touchscreen, plus unparalleled benefits like energy monitoring and production efficiency. Witness the machine's .

cb750 santee electrical box

Injection Molding and CNC Machining, while seemingly similar, operate on fundamentally different principles. Injection Molding, akin to casting, molds molten materials into predefined shapes. CNC Machining, in contrast, . The typical considerations for CNC machining vs Injection molding are material, shape complexity, production volume, wall thickness, and required tolerances. Furthermore, there are other alternatives to plastic molding and . Shibaura Machine (FKA Toshiba Machine) is a leading global manufacturer of precision injection molding machines, machine tools, & die casting machines. Call us!

FANUC ROBOSHOT takes state-of-the-art CNC precision technology from turning and milling and applies it to electric injection moulding. The results are greater acceleration, ultimate precision of movement and extremely short .Shibaura Machine is a leading global manufacturer of high precision injection molding machines. Our North American headquarters, centrally located in Elk Grove Village, IL, is fully equipped to support sales, service, parts, mold trials, .

Injection molding and CNC machining are two widely used manufacturing processes that shape materials into desired forms. While both processes involve shaping material, they differ significantly in their approach, . What is injection molding? Injection mold making is the go-to method for mass-producing plastic parts. The process is streamlined to maximize cost savings and part production. First, pelletized material is placed into a .We have provided precision injection molding machines to the North American market since 1974 and have an installed base of over 15,000 injection molding machines. Our global manufacturing and world-class engineering capability, .

CNC Machining & Precision Injection Molds - We are Leading CNC Machining Services, Precision Injection Molds and Plastic Molded components. [email protected] +91-9958862327; . Our humble beginnings, started . CNC machining Vs. Injection molding. The designs are created on CAD/CAM software, and then instructions are forwarded in the form of G-codes to different machines to execute the operation. The smooth transition between .Shibaura Machine (FKA Toshiba Machine) is a leading global manufacturer of precision injection molding machines, machine tools, & die casting machines. Call us! Shibaura Machine Company America is leading global manufacturer of precision injection molding machines, machine tools, and die casting machines. If you're interested in Injection Moulding, then Victor CNC supply high performance moulding machines. Advanced technology means you can produce more compone.

Injection molding and CNC machining each offer product teams a range of respective strengths and pitfalls. Design variation is typically difficult to achieve economically via injection molding, whereas custom CNC plastic parts can be manufactured quickly, in smaller numbers, and from specialty materials. . then re-machine the mold to include .injection molder, injection molding, injection machine, cnc machine, cnc router, cnc machining, swiss lathe, swiss machining; APSX machines in industry. APSX machines in education. ABOUT US. We create SIMPLE solutions with ADVANCED technology.Next-generation manufacturing technology for injection molding, CNC machining and more. 24-hr quote turnaround. Medical devices, ISO 13485, ISO 9001. What Sets Us Apart? . Injection Molding Machines . 15+ RTV & Vacuum Casting Systems . 30+ High Speed Mills & Lathes . Get A Quote . Let us impress you. . Injection molding and CNC machining are two widely used manufacturing processes that shape materials into desired forms. While both processes involve shaping material, they differ significantly in their approach, capabilities, and applications. . Setup: The CNC machine is set up with the appropriate cutting tools and workpiece. Machining: .

CNC machining is the leading production style for mold making. Molds are most commonly machined out of tool steel and stainless steel, but aluminum is also used occasionally. Aluminum doesn’t hold up to the wear and tear of injection molding as well as steel, but it is an inexpensive alternative for small batches of injection molded parts.CNC machines, on the other hand, may work around the clock. The controller can programme the computer and instruct the machine to make the required part based on the project’s design. . Both injection moulding and CNC machining are high-quality technologies for producing the greatest products possible, but each has its own set of advantages .CNCPrices Buys and Sells used and re-manufactured CNC Machines. We commonly save companies up to 60% off retail. . Husky 1000 Ton Injection Molding Machine 109 oz shot size View This Machine -> HPM 1000 Ton Injection Molding machine View This Machine -> Husky HL400 Ton Hylectric +Robot Krauss Maffei Systems Injection Molding Machine View This .

Rely on the best in injection moulding technology: our modular product range includes hydraulic, hybrid and electric injection moulding technology – from consistently standardised entry-level models to customised machines. From performance variants to high-speed machines. Our ALLROUNDERs make everything possible. Injection moulding machines Setup on Injection Molding Machine; Special micro injection molding machines are used, which are able to process minimal volumes of the processed material. The settings of a machine include temperature, pressure, and injection speed, and are adjusted according to the type of the material and geometry complexity. Material Melting and InjectionELK GROVE VILLAGE, IL, June 15, 2018 - The U.S. Injection Molding Div. of Shibaura Machine completed its move into a 58,000 square foot facility in Elk Grove Village, Ill., replacing a a smaller facility in Elgin, Ill.Our modern toolroom is equipped with the latest CNC machinery for creating custom components and precision parts. Learn more. Product design. Head brimming with product ideas? . 90, 120, 250 and 380 tonne tonne plastic .

Typical tolerances achievable with PEEK injection molding are within ±0.05mm. Achieving precise tolerances depends on several factors, including mold design, machine capabilities, and processing conditions. . CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material .13 years of CNC machining experience. The company was founded in 2010. The company started from a small workshop with 5 CNC machines. After experiencing a difficult startup period, the business grows rapidly. Three years later, we moved to a larger plant and added 10 milling machines and 1 lathes. CNC machining and injection molding are two common ways to make actual products in different industries. In CNC machining, manufacturers use metal cutters to remove unnecessary materials from the final product, whereas, in injection molding, liquid plastic is shaped in mold form to produce the final product. Injection molding is mainly limited to plastics and resins. CNC machines are generally better able to produce using more rigid materials, like metals and hard plastics, due to the machine’s high heat tolerance. While CNC machines can cut into more pliable material, the risk of warping can be higher depending on the machining method used.

CNC machines used for plastic processing are typically advanced multi-axis systems that are computer-controlled for precision and accuracy. Machining is considered a subtractive manufacturing method because the machine, whether mill, lathe, or router, removes material from a stock shape or injection molded blank. . The best advice is to . Simultaneously, plastic pellets or granules are fed from a hopper into the heated barrel of the injection molding machine. 2. Melting and Injection: The plastic pellets are melted by heater bands wrapped around the barrel as a reciprocating screw moves them forward. The molten plastic is then injected under high pressure through the nozzle and .

I am looking to purchase a desktop scale injection moulding machine which can be used for university undergraduate engineering teaching. We would like to do some simple lab experiments demonstrating the effects of injection parameters (material, temp, pressure etc) on the performance of parts.The Arcuchi Injection Molding Machine Controller is an advanced PLC control system designed to optimize the operation of injection molding machines. Arcuchi Injection molding controller is widely used manufacturing process in which molten material is injected into a mold to create various plastic products. To ensure precision, efficiency, and .

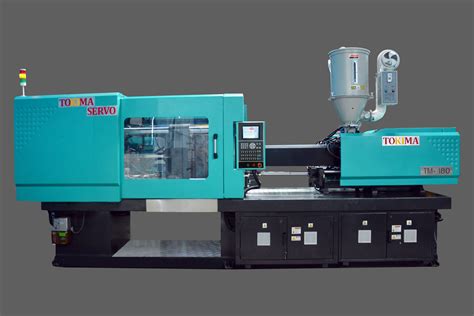

IMTS 2024 See You at IMTSWe are excited to work together with our customers and partners to change the standard in manufacturing. Be sure to visit us at Booth 339424 to view the BTD-110S.R16 and TUE-200(S) machines, while seeing how our .CNC mold making machine with automatic tool changer is a type of CNC router for metal moulding. Now the best CNC molding machine for sale at affordable price. . drilling most materials, including copper, aluminum, steel, iron, brass, wood, foam, and plastics. It is widely used in injection mould, automotive, ironware mould, shoe mold, drop .The design and manufacture of injection moulding cnc machines comply with ISO international standards, and the units of measurement for all parts of the machine tools and various instruments all adopt international unit standards. CNC machining of precision parts, workpiece clamping can complete milling,reaming,boring,drilling Various processes .

injection moulding machines full details

injection moulding machine types

ce certification cnc milling service quotes

injection moulding machine manufacturers

Leading steel and metal building wholesalers & manufacturer in Colorado area's. Explore durable solutions for your projects with our trusted expertise. Premier Steel Buildings – Engineered & Manufactured in the U.S.A.

injection moulding cnc machines|injection moulding machine manufacturers