sheet metal articles In a sheet forming process, a thin piece of metal sheet, commonly referred to as .

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the .

0 · which thickness called sheet metal

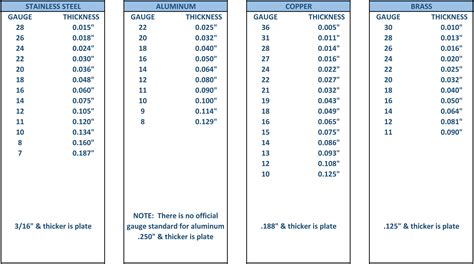

1 · types of sheet metal material

2 · types of sheet metal fabrication

3 · metal sheet thickness in mm

4 · maximum thickness of sheet metal

5 · disadvantages of sheet metal

6 · different types of sheet metals

7 · characteristics of sheet metal

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components.

This paper aims at scattering light on the recent research and developments in the sheet metal forming processes over the last two decades. Most of the literature available on .The sheet metal industry has seen more technological advances than any other .The blanking process is classical elasto-plastic large deformation. As Fig. 1 .

The geometry of the blanking process modelled in this study is presented in .Optimization of process parameters in sheet metal forming is an important task to .In a sheet forming process, a thin piece of metal sheet, commonly referred to as .Sheet metal forming is an effective means of producing sheet metal parts in .

In a sheet forming process, a thin piece of metal sheet, commonly referred to as the blank, is bent or stretched by tools into a desired shape without excessive thinning, tearing, or wrinkling. .Sheet metal forming is an effective means of producing sheet metal parts in complex three-dimensional shapes with a minimum of material. This conventional process involves a set of . Uncover the secrets of sheet metal: materials, geometries, and processes. Explore the world of stainless steel, carbon steel, and aluminum. The Fabricator provides metal fabrication professionals with market news, the industry's best articles, product news, and conference information from the Fabricators and .

Explore the latest full-text research PDFs, articles, conference papers, preprints and more on SHEET METAL. Find methods information, sources, references or conduct a literature review .This page features a range of technical articles and reports, eupdated on a daily basis, relating to the sheet metal, machine welding and boiler making industry.. Whether you are a subcontracted sheet metal worker, or a manufacturer of your own products, you will find technical information about different technologies and production processes, such as: cutting (laser, punching, .

Explore the latest full-text research PDFs, articles, conference papers, preprints and more on SHEET METAL FORMING. Find methods information, sources, references or conduct a literature review on . The sheet metal industry has seen more technological advances than any other since the last century. Right from hand-forming processes to finite element based simulation, the transformation is very significant. They have prominent industrial applications especially in automotive industries. This may be attributed to the ease with which the .Sheet Metal Journal is owned and operated by Point One Media Inc. Tel: 877.755.2762 .

This article focused on seven of the most common mistakes in sheet metal bending, providing provide practical tips to avoid them. By incorporating proper bend relief, calculating bend allowance accurately, and ensuring adequate support across flanges, you can be sure your parts will transition seamlessly from CAD, through our app , and into . As the application of sheet metal continues to expand, the design of sheet metal parts has become a critical aspect of product development. Mechanical engineers must be well-versed in the design of sheet metal components to ensure that the parts meet the necessary functional and aesthetic requirements while keeping the stamping die production .At last, Metal-Interface unites the sheet metal industry across several countries with complementary services: news, adverts, job offers and knowledge sharing via a sheet metal wiki. For all questions, do not hesitate to contact us: Metal-interface.com, the leading website created by and for professionals in the field of sheet metal forming, in .

Sheet metal fabrication is one example of a complex process chain. Nearly all component assemblies being manufactured from sheet metal are produced by a sequence of cutting and joining techniques. Hitherto, these different processes were carried out on different machines. The sheet components are successively prepared by cutting, joined .

Explore the latest full-text research PDFs, articles, conference papers, preprints and more on SHEET METAL. Find methods information, sources, references or conduct a literature review on SHEET METAL Introduction. Sheet metal manufacturing is a fundamental part of modern industry, transforming raw metal into essential components for a wide range of products, from consumer electronics to heavy machinery. This precision-driven process transforms flat metal sheets into intricate components. Over the decades, sheet metal manufacturing has evolved from manual .

In a progressive-die operation, a decoiler is used at the front of the line where the sheet metal feeds into a press with constant pitch after each stroke. Progressive-die press lines employ a single press, anywhere from 200 to 1250 tons. They can run at moderate speeds, typically between 30 and 70 strokes/min. for small parts, and in some .

4.2 Fundamentals of Sheet Metal Forming. In recent years, the application of simulation tools designed for the sheet forming industry has increased considerably. These tools have been developed on top of the basic mechanics that describe the behavior of sheet metal material under various deformation conditions such as bending and stretching. A .Related Articles. Sheet Metal: Convert to Sheet Metal. Number of Views 1.71K. Setting thickness and bend radius for a Sheet Metal part. Number of Views 2.96K. Sheet Metal: Material and Bend Table Improvements. Number of Views 1.29K. How to unfold a .Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel.

china cnc machine shop quotes

We would like to draw your attention to this Special Issue of JMMP on “Analysis and Modelling of Sheet Metal Forming Processes”. Analysis and modeling play a vital role for accessing the feasibility of sheet metal forming processes. Nowadays, almost no tool design in industrial stamping is manufactured without successful virtual tryout. The sheet metal fabrication industry is undergoing a profound transformation, driven by technological advancements, sustainability concerns, and changing market demands. This article explores the future of sheet metal fabrication, highlighting key trends and forecasts that are shaping the industry’s evolution.NX12 has been a well-received release from Sheet Metal users. This is the sixth article in a series highlighting what’s new. Convert to Sheet Metal is a valuable command when importing models from other CAD systems, neutral file .

The Sheet Metal Occupational Health Institute Trust (SMOHIT), a leading organization dedicated to the health and safety of unionized sheet metal workers, has appointed Jeff Bradley as its new program administrator. Bradley, who most recently served as SMOHIT's program director, brings a wealth of experience and a passion for innovation to his . Sheet metal is one of the shapes and forms metal can be bought in. Sheet metal is any metal that has a thickness in between 0.5.6 millimetres. There are other measurement units used to categorise metals by thickness, though. Millimetres, Mils & Gauge. However, during sheet metal forming, tools contact undeformed sheet in every case. In this article I’ll focus on the strip-draw test. During a strip-draw test, clamping force (F c) is adjusted using a screw, or with a hydraulic system. Then the test apparatus pulls the sheet at constant speed as researchers record the pulling force (F p). In .In this article alone, fourteen types of sheet metal fabrication are mentioned. These varying techniques allow make it possible to create relatively complex parts by cutting flat sheets, bending parts into place and adding holes, slots, and notches cut in all the right places.

Definition of sheet metal. While no universally accepted definition of sheet metal exists, industry consensus generally characterizes it as follows: Sheet metal refers to thin, flat metal material, typically less than 6 mm (0.25 inches) in thickness, that serves as the primary input for a comprehensive range of cold-forming manufacturing processes. In sheet metal fabrication, curving sheets according to a specific bend radius is one of the most common operations used to create flanges, curls, seams etc.Moreover, bending imparts much strength to the sheet metal compared to their flatter counterparts. For example, an aluminium sheet bent into a V cross section will be much stiffer and stronger than the same flat . Empirical Comparison of Unsupervised Deep Learning Models for Anomaly Detection in Images of Sheet Metal Glue Lines. 41 Pages Posted: 13 Nov 2024. See all articles by Siyuan Chen Siyuan Chen. . Subscribe to this fee journal for more curated articles on this topic FOLLOWERS. 754. PAPERS. 672. Quality Management eJournal. Follow. Quality .

Ever wondered how intricate shapes and precise bends are created in sheet metal? This article dives into the fascinating world of folding machines, revealing their essential role in bending and. Sheet Metal Fabrication Handbook – Forming . How does a flat metal sheet transform into complex shapes and structures? .A comparison of traditional and modern forming methods is presented here in an attempt to illustrate the evolution of different incremental sheet metal forming techniques. Emphasis is placed on conventional spinning, shear forming and modern computer-controlled forming methods that are currently being studied. Sheet metal screw size conversion. Sheet metal screws are used with metallic and non-metallic materials that are too thin to tap. They are also used when rear access is obstructed, preventing the installation of a nut. Sheet metal screws are typically reusable, one-piece, high-strength fasteners that can be removed for maintenance and repair. .

which thickness called sheet metal

types of sheet metal material

An electrical junction box is a very important part of your electrical wiring system. Without a junction box, you simply cannot have that many different types of electrical outlets, switches, or data hookups in a room.

sheet metal articles|types of sheet metal fabrication