what kind of welding is used for sheet metal manufacturing What are the common types of welding for sheet metals? There are five common welding approaches for sheet metal, including TIG, MIG, Stick, Laser beam & plasma welding. What is the thickness limit for sheet metal . $74.95

0 · welding sheet metal guide

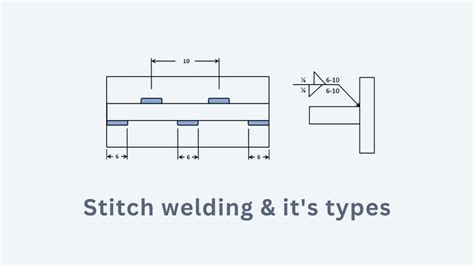

1 · stitch welding sheet metal

2 · sheet metal welding process

3 · sheet metal welding parts

4 · sheet metal welding methods

5 · metal welding sheet metal

6 · how to weld sheet metal

7 · approved sheet metal welding

UNO, Care Bears, Special Edition Card Game, Metal Box, Board Game, Activity, Travel, Playset, Collectible, Vintage, ~MISC-002 Nice UNO, Care Bears card game, in the metal box. Fun .

Fab shops typically employ several welding methods, including spot welding, tack welding, fuse welding, stitch welding, plug welding, seam/fillet welding, MIG welding, and TIG welding, each with unique applications and .

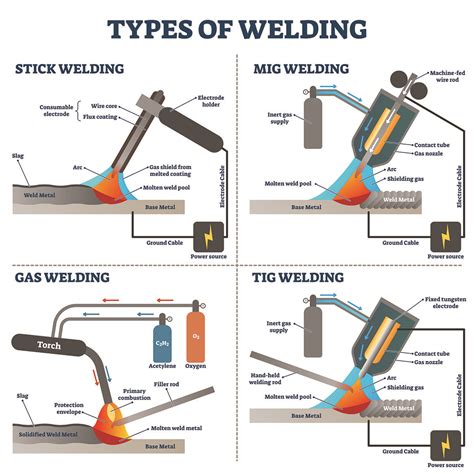

One of the most commonly used welding techniques in sheet metal manufacturing is MIG (Metal Inert Gas) welding. MIG welding utilizes a wire electrode fed through a welding gun and melting to form a bond between the .Sheet metal welding is a welding process used to join thin metal sheets, usually involving metal materials with a thickness of 1/16 inch (about 1.5 mm) to 1/4 inch (about 6 mm). Arc Welding: Arc welding uses an electric arc to generate intense heat, melting metals so they can fuse together. It’s widely used in construction and repairs because it works . What are the common types of welding for sheet metals? There are five common welding approaches for sheet metal, including TIG, MIG, Stick, Laser beam & plasma welding. What is the thickness limit for sheet metal .

A well-known welding type, MIG welding (can also be called Gas Metal Arc welding) uses a solid wire electrode in a welding tool to create a pool of melted wire which then becomes the filler material that connects the metal .Ready to roll up your sleeves and get down to the nitty-gritty? Table of contents Hide. 1 Safety Precautions and Gear. 2 What are the common types of welding for sheet metal? 3 How can I ensure the best quality when welding sheet .

We’ll show you the different welding procedures available and give some important tips for welding sheet metal. What is Sheet Metal Welding? Welding involves joining two metals using either heat, pressure, or a combination of both. Spot welding, or Resistance Spot Welding (RSW), is a technique used to join metal sheets by applying electrical current and pressure to create a small, localized weld. It’s .

This article will provide a detailed introduction to common methods and techniques for sheet metal welding, including the types of metals used, tips, and the factors to consider when selecting a welding method. . From Concept to .

Spot welding — which is a type of resistance welding — is often used in the automotive industry to join sheet metal frames together. Arc Welding. Arc welding is often used in high-volume production because of its high . Welding is a process that joins metal parts together. It is one of the most common methods for making connections between metal objects, and there are many different types of welding. is Sheet metal welding a subset of . Sheet metal welding is a crucial process in various industries where joining thin metal sheets is necessary to fabricate structures, components, and assemblies. This welding method plays a vital role in industries such as automotive, aerospace, construction, and manufacturing. So, You never want to go wrong with sheet metal welding. Read this article, .

3 Methods of Welding Sheet Metal: There are many different methods for sheet metal welding, but the three we are going to discuss are MIG (metal inert gas), TIG (tungsten inert gas), and laser welding. The method used will depend on many factors. Below are things to consider for each of the three methods. MIG weld: Process – Use a light touch: When welding sheet metal, it is important to use a light touch to avoid overheating the metal and causing warping or other distortions. Use short welds and allow the metal to cool between welds. – Use a filler rod: When welding sheet metal, it is often necessary to use a filler rod to join the metal pieces together. By the early 20th century, electric welding reached a technological sophistication where it became mainstream in metal joinery. According to the Fabricators & Manufacturers Association, shielded metal arc welding is still the most popular form of electric welding despite many high-tech advancements made in the welding field.SMAW is easy to learn and highly .Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000.

In metal fabrication, fabricators create metal parts from raw source metals like steel, copper or aluminium.They’ll use methods like cutting, punching, bending, and welding to fabricate the parts needed for a project. Sheet metal fabrication specifically uses all of the same processes, but only flat metal sheets are used as the source to create the products. Also known as Metal Inert Gas (MIG) welding, GMAW is one of the automobile industry’s most commonly used welding techniques. This process uses an electric arc to melt the metal to join the parts. A shielding gas – usually a mixture of carbon dioxide and argon – protects the weld from contamination. Sheet and plate metal welding is a crucial aspect of metalworking, playing a fundamental role in various industries. From joining intricate designs in automotive manufacturing to constructing large-scale structures, welding these thin metal forms requires precision, skill, and an understanding of different techniques. Welding is the most common technique used to fabricate sheet metal. However, there is no one particular welding technique that is employed for this purpose. Sheet metal manufacturers use different types of welding methods for sheet metal fabrication. The method chosen differs as per the metal being fabricated and the desired end product.

Learn about the techniques used in sheet metal fabrication and the different types of welding, along with safety measures to consider. Manufacturer of Metal Working Machinery 1-800-391-5419 TIG welding, or Gas Tungsten Arc Welding, is a more complex welding process that yields an attractive finished product. Similar to the aforementioned MIG method, shielding gas is used along with an electrical arc which is created between the base material and a tungsten electrode to melt the metal.

Introduction. Sheet metal manufacturing is a fundamental part of modern industry, transforming raw metal into essential components for a wide range of products, from consumer electronics to heavy machinery. This . Laser welding is a cutting-edge production technique that utilizes a laser with high energy density as the heat source for welding. It is widely used in the sheet metal manufacturing industry due to its advantages, including high . Learn about some common sheet metal forming processes and their unique qualities. 5 Common Types of Metal for Welding. The following types of metal are commonly used for welding: 1. Aluminum. Aluminum is one of the most popular materials for welding due to its light weight, strong corrosion resistance, and high conductivity.I typically use one drawing per individual sheet metal part, and if it is welded that is treated as one weldment part. The individual sheet metal parts are inserted into the weldment part. However, if the weldment contains extrusions then those compoments are all created inside the weldment due to the ease of generating a cut list, creating .

One common testing method is the cupping test, where a ball is placed on the sheet and pressed into it until the material fails. Once it is determined how much and what type of tension is ideal for the desired form, that tension is applied to shape the metal. 4. Welding. Most sheet metal is manufactured to be a part of a greater whole.

welding sheet metal guide

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, . If multiple holes are desired, the same equipment type can be used to make them. 2. Deformation . . Welding is another method for joining sheet metal components. The two pieces’ molten metal fused into a solid joint in welding. With various metal alloys and manufacturing processes like galvanizing and electroplating determining the types of metal sheets, each can be differentiated accordingly. On that note, it’s time to get into the depth of the 9 types of sheet metals and their diverse uses. So, without further ado, let’s dive in. Basics of Sheet Metals

Of these methods, the best one for welding thin metals is MIG welding. This is the most common type of welding that people in manufacturing use for welding sheet metals, which are thin pieces of metal. You can also pulse when . Used to remove oils and dirt from metal during the forming, welding, and sizing processes. Typically drained and removed after use. Cutoff Oil : Emulsifiable : Welding process turns residual oils into fumes. Minimize use; apply to blade only. Storage Coating : Emulsifiable : Welding process turns coating into fumes. Minimize use.Types of Welding Used for Sheet Metal. Some of the most widely used welding methods include: MIG Welding (Metal Inert Gas Welding) . In automobile manufacturing, sheet metal plays a critical role, particularly in the production of vehicle bodies and structural components. Steel and aluminum are the most commonly used materials.

In this type of welding, the welding equipment and materials must be moved to the job site, and welding processes are performed using specialized welding techniques. . Spot welding is commonly used for welding sheet metal, which makes it especially useful for applications such as automotive manufacturing and sheet metal fabrication .

When running a fabrication, manufacturing, or construction business, welding sheet metal is sometimes necessary. Not only are there are many kinds of metals to weld-some easy, others near impossible-but there are also different welding terminologies. For example, terms like “TIG and MIG welding” are so similar that they are often confused. Industrial sheet metal fabrication is a versatile and essential process that involves shaping, cutting, and manipulating sheet metal to create a wide range of products and components. The choice of materials plays a crucial role in determining the strength, durability, and performance of fabricated metal parts. In this blog post, we will explore some of the .

metal fabricator salary austin tx

Choose from our selection of square tubing brackets, including bolt-together framing and fittings, press-fit framing and fittings, and more. In stock and ready to ship.

what kind of welding is used for sheet metal manufacturing|sheet metal welding methods