sheet metal manufacturing drawings Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

What is a Septic Distribution Box and How Does it Work? A septic tank distribution box, or D-box, is a junction box that connects the outlet pipe from the septic tank to the multiple distribution .

0 · simple sheet metal drawings

1 · sheet metal layout drawings

2 · sheet metal fabrication drawings pdf

3 · metal sheet riveted together drawing

4 · metal sheet mechanical drawings

5 · free sheet metal templates

6 · free sheet metal layout software

7 · free sheet metal layout patterns

Sporting a 24” x 24” cutting area, Bob’s CNC Evolution is a great CNC router Kit made from quality materials that come together to create a solidly built reliable machine. It will make smooth and precise cuts on all three axes .

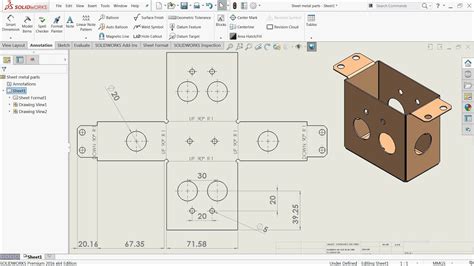

Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, . 5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. Follow these best practices next time you create a sheet . Two-dimensional (2D) drawings are fundamental in the sheet metal fabrication sector. These drawings are graphical representations of the final product, carrying comprehensive details about dimensions, material specifics, .

What is deep drawing in sheet metal fabrication? Deep drawing is a process where sheet metal is radially drawn into a forming die, producing a deep, hollow shape like cans or caps. The depth of the drawn parts often .

Our design guide to properly drafting sheet metal drawings and specifications for your supplier to get more accurate quotes and faster design for manufacturing (DFM) feedback.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including .

“ Sheet metal fabrication drawing is a valuable process for making final-use products. Accuracy in drawing aluminum ensures smooth production, efficient material use, and high-quality standard parts.” . This guide will focus . Benefits of Sheet Metal Fabrication Drawings. Investing in high-quality sheet metal fabrication drawings yields a multitude of benefits throughout the manufacturing process: 1. Ensuring Accuracy and Reducing Errors: .i worked at a large company with a world-class sheet metal manufacturing plant attached. we were required to provide a flat pattern view with each sheet metal drawing, but dimensions were not required. the purpose here was to "prove" that the part in the drawing could be made from a single non-overlapping sheet of metal. basically it was a .

Ironing of sheet metal is a manufacturing process that is mostly used to achieve a uniform wall thickness in deep drawings. Variation in wall thickness often exists in parts produced by deep drawing, as discussed in the previous section. Figure 5-1: Sheet Metal Box 5.1 REQUIRED VIEWS Formed sheet metal parts must be fully defined as a finished good in the completed (folded) state per section; however, sheet metal parts also require specific data to be shown on the drawing to ensure proper manufacturing and inspection. Sheet Metal drawing process. Sheet metal drawing is not merely a process but an art, where flat metal sheets transform a three-dimensional shape by getting drawn over a die without thinning or altering the sheet’s thickness. This subtle yet complex operation is pivotal for industries aiming to produce accurate and consistent hollow shapes.

Design Sheet Metal Parts with the Manufacturing Process in Mind. In order to successfully manufacture a product made of sheet metal, it is important to have a detailed and accurate design. . The ASM team has reviewed tens of thousands of sheet metal drawings over the years. Our experience allows us to [.]or another heat treatable metal with good ductility may need to be used. The part may require heat-treating after forming to achieve necessary stiffness or spring performance characteristics, which adds to manufacturing cost. Note that broad flat sections in high carbon spring steel parts tend to warp during heat treating. Where potential warpingYou will get a sheet metal Fabrication Drawings for manufacturing MANIKANDAN S. MANIKANDAN S. 4.9 (171 171 reviews ) Top Rated Share Let a pro handle the details. Buy 2D Product Drawing services from MANIKANDAN, priced and ready to go. How it works Project Catalog; Design .

Getting the correct way of dimensioning in sheet metal fabrication drawings. Best design practices should be followed so that the 3D dimensions match the 2D design. This is of course, now much easier to do with modern CAD software and tools. The following reference pictures and information illustrate the correct dimensioning information to give .Our experts in sheet metal design are dedicated to provide high-quality sheet metal part drawings, models, and fabrication drawings to ensure smooth manufacturing. About Us; Services. Furniture Design Drawings . Our CAD engineers and sheet metal design experts collaborate with your shop floor engineers to deliver metal fabrication drawings .

Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. . Deep drawing machinery is similar to that of the shear punch but this time there is more clearance between punch and die which . Having a clear list of important quality metrics in sheet metal fabrication drawings sets the foundation for manufacturing efficiency. Some key design quality control techniques that design engineers use at this stage include: Detailed CAD Design: Precision in CAD drawings for sheet metal fabrication is non-negotiable. Ensure that every detail .But 10 years ago, the industries I worked in relied solely upon traditional drawings for manufacturing and inspection. Reply reply [deleted] • . I worked for a place where just about everything was CNC machined or sheet metal and we fully dimensioned drawings. Now I design molded and cast parts and pretty much only do critical and . sheet metal fabrication| sheet metal processing| cnc machining| precision machining| sheet metal stamping| steel sheet metal fabrication . Drawings' Functions and Roles in CNC Machining Conveying design intention The CNC machined product starts with one expression: a drawing. A drawing is the visual language of engineering.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which . If a drawing or specification sheet has not been provided by the customer, Xometry willOur CAD drafters provide SolidWorks sheet metal 3D modeling services, detailed sheet metal shop drawings to fabricators and building product manufacturers. . So, sheet metal fabrication involves processes such as cutting, bending, and assembling metal sheets into the desired shapes and structures. In contrast, sheet metal machining involves . Leveraging CAD software for sheet metal fabrication shop drawings creation. Using CAD platforms to create shop drawings is a game changer for sheet metal fabrication companies. CAD tools like .

Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude, etc.), and then insert bends or convert to sheet metal. However, these options are problematicDownload our guide on the quality check process for sheet metal CAD drawings, ensuring accuracy, compliance, and improved efficiency in design and manufacturing. . Case Study: 3D Modeling & Fabrication Drawing for Stairlifts, Europe; Case Study: SolidWorks 3D Models & Part Drawings for Steel Shelter, USA; Unlock Your Resource!A deep drawing is a manufacturing technique that transforms a metal sheet into a three-dimensional form through mechanical action. Usually executed using a punch, die, and other tools, this method is perfect for hollow, axisymmetrical parts.

Give me the drawing of the final part, and I'll do the sheet metal layout. There are a lot of adjustments that have to be made to a sheet metal part to get things to line up in the end. A 1/4in hole isn't a 1/4in hole. It's a hole for a 1/4in bolt, so .255 for a close fit and .265 for a loose fit. Sheet metal grows/moves when you bend it.Fabrication drawings is a specific type of Sheet metal, Pipe, Duct & Angles detail drawing for manufacturing purpose. Detail drawings identifying parts, materials, welding details with standards symbols. The fabrication drawing is a specific type of Sheet metal, Pipe, Duct. +91 9841 83 20 67. info[@]microdra.com. Home; About Us; Services.

Fast and easy sheet metal shop drawing services. 3D duct drawing with sizes of duct, part number, and material list for parts for fabrication. Search for: 610-287-1542 [email protected] Fabrication as a service is only as good as the drawings that fabrication is based on. A simple fabrication drawing must be precise in order to be easily understood and ultimately effective when viewed and followed by the shop. There are various levels of detail and quality involved, especially as you debate fabrication drawing versus shop drawing, but the following . Sheet metal forming is a sheet metal fabrication process that manipulates metal into flat sheets into complex shapes. Employed extensively across various industries, this technique involves a range of operations such as bending, drawing, and punching.

simple sheet metal drawings

sheet metal layout drawings

sheet metal fabrication drawings pdf

Sigma's weatherproof two-gang boxes provide a junction for conduits and can house up to two wired devices such as a receptacle or switch. The rugged, die-cast construction prevents .

sheet metal manufacturing drawings|free sheet metal layout patterns