cnc machine for helicopter rotor blades 1940 For 40 years, he worked at Parsons Corporation, which became a world leader in production of helicopter blades, and produced fuel tanks for the . From custom aluminum extrusions that require basic procedures (such as precision cutting, drilling, tapping or punching) to fully finished components and assemblies, FINE offers full .

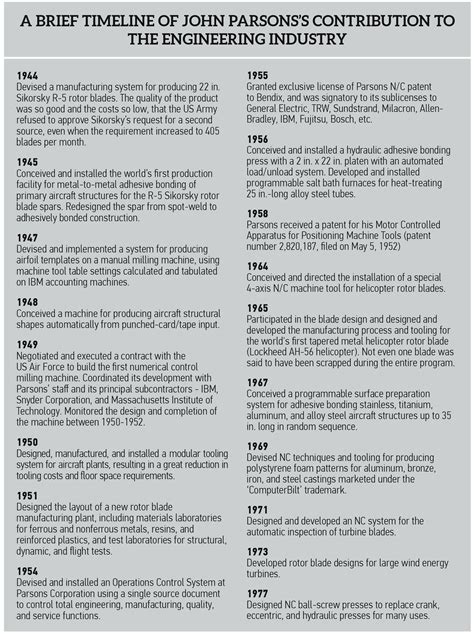

0 · REMEMBERING JOHN T PARSONS A BRIEF TIMELINE

1 · REMEMBERING JOHN T PARSONS

2 · John T. Parsons History Project

3 · John T. Parsons

4 · John T Parsons

5 · History of CNC Machining — James Engineering

6 · Computer Pioneers

7 · About: John T. Parsons

Dive into our online wholesale oem metal stamping parts products catalog on globalsources.com! Source over 3493 oem metal stamping parts for sale from manufacturers with factory direct prices, high quality & fast shipping.

John T. Parsons (October 11, 1913 – April 18, 2007) pioneered numerical control (NC) for machine tools in the 1940s. These developments were done in collaboration with his Chief Engineer .4-axis N/C machine tool for helicopter rotor blades. 1965 Participated in the blade design and designed and developed the manufacturing process and tooling for the world's first tapered .

Conceived and directed the installation of a special 4-axis N/C machine tool for helicopter rotor blades. Participated in the blade design and conceived the manufacturing process and tooling for the first tapered metal helicopter rotor . For 40 years, he worked at Parsons Corporation, which became a world leader in production of helicopter blades, and produced fuel tanks for the .Parsons is an exceedingly interesting case study of how industrial and engineering supply firms—in this case, Parsons notably made ordnance casings and fins in World War II, then helicopter rotor blades in the 1940s, '50s, and .

John T. Parsons (October 11, 1913 – April 18, 2007) pioneered numerical control (NC) for machine tools in the 1940s. These developments were done in collaboration with his Chief Engineer .His company had made a number of manufacturing innovations in producing land mines, bombs, rockets, and helicopter rotor blades during World War 11. In 1947 he and Frank Stulen .

Their origins can be traced back to the 1940s and a man named John Parsons. Parsons was an engineer who initially started working for Sikorsky Aircraft building helicopter rotor blades, but when they started to fall, he knew he had .

Together, they were the first to use computer methods to solve machining problems, in particular, the accurate interpolation of the curves describing helicopter rotor blades. In the 1940s, a ‘computer’ meant a punch card . Together, they were the first to use computer methods to solve machining problems, in particular, the accurate interpolation of the curves describing helicopter rotor blades. In 1946, "computer" still meant a punched .

REMEMBERING JOHN T PARSONS A BRIEF TIMELINE

metal tool box design plans

John T. Parsons (October 11, 1913 – April 18, 2007) pioneered numerical control (NC) for machine tools in the 1940s. These developments were done in collaboration with his Chief Engineer and Vice President of Engineering, Frank L. Stulen , who Parsons hired when he was head of the Rotary Wing Branch of the Propeller Lab at Wright-Patterson .4-axis N/C machine tool for helicopter rotor blades. 1965 Participated in the blade design and designed and developed the manufacturing process and tooling for the world's first tapered metal helicopter rotor blade (Lockheed AH-56 helicopter). Not even one blade was said to have been scrapped during the entire program. 1967

Conceived and directed the installation of a special 4-axis N/C machine tool for helicopter rotor blades. Participated in the blade design and conceived the manufacturing process and tooling for the first tapered metal helicopter rotor blade (Lockheed AH-56 helicopter). Not even one blade was scrapped during the entire program. For 40 years, he worked at Parsons Corporation, which became a world leader in production of helicopter blades, and produced fuel tanks for the Saturn rockets that took astronauts to the moon. Parsons’s breakthroughs in computerized manufacturing led to the development of Computer Numerical Control (CNC), which controls the automation of .Parsons is an exceedingly interesting case study of how industrial and engineering supply firms—in this case, Parsons notably made ordnance casings and fins in World War II, then helicopter rotor blades in the 1940s, '50s, and '60s (which is where he developed numerical control [NC] machining), and eventually fiberglass boats for the leisure .

John T. Parsons (October 11, 1913 – April 18, 2007) pioneered numerical control (NC) for machine tools in the 1940s. These developments were done in collaboration with his Chief Engineer and Vice President of Engineering, Frank L. Stulen, who Parsons hired when he was head of the Rotary Wing Branch of the Propeller Lab at Wright-Patterson Air .His company had made a number of manufacturing innovations in producing land mines, bombs, rockets, and helicopter rotor blades during World War 11. In 1947 he and Frank Stulen developed a method to produce contoured templets for checking blades by calculating successive machine positions on an IBM multiplier and then manually setting the .

metal tool box with soft pvc handle supplier

Their origins can be traced back to the 1940s and a man named John Parsons. Parsons was an engineer who initially started working for Sikorsky Aircraft building helicopter rotor blades, but when they started to fall, he knew he had to find a better solution to building them.Together, they were the first to use computer methods to solve machining problems, in particular, the accurate interpolation of the curves describing helicopter rotor blades. In the 1940s, a ‘computer’ meant a punch card-operated calculation machine. Together, they were the first to use computer methods to solve machining problems, in particular, the accurate interpolation of the curves describing helicopter rotor blades. In 1946, "computer" still meant a punched-card operated calculation machine.John T. Parsons (October 11, 1913 – April 18, 2007) pioneered numerical control (NC) for machine tools in the 1940s. These developments were done in collaboration with his Chief Engineer and Vice President of Engineering, Frank L. Stulen , who Parsons hired when he was head of the Rotary Wing Branch of the Propeller Lab at Wright-Patterson .

4-axis N/C machine tool for helicopter rotor blades. 1965 Participated in the blade design and designed and developed the manufacturing process and tooling for the world's first tapered metal helicopter rotor blade (Lockheed AH-56 helicopter). Not even one blade was said to have been scrapped during the entire program. 1967Conceived and directed the installation of a special 4-axis N/C machine tool for helicopter rotor blades. Participated in the blade design and conceived the manufacturing process and tooling for the first tapered metal helicopter rotor blade (Lockheed AH-56 helicopter). Not even one blade was scrapped during the entire program.

For 40 years, he worked at Parsons Corporation, which became a world leader in production of helicopter blades, and produced fuel tanks for the Saturn rockets that took astronauts to the moon. Parsons’s breakthroughs in computerized manufacturing led to the development of Computer Numerical Control (CNC), which controls the automation of .Parsons is an exceedingly interesting case study of how industrial and engineering supply firms—in this case, Parsons notably made ordnance casings and fins in World War II, then helicopter rotor blades in the 1940s, '50s, and '60s (which is where he developed numerical control [NC] machining), and eventually fiberglass boats for the leisure .John T. Parsons (October 11, 1913 – April 18, 2007) pioneered numerical control (NC) for machine tools in the 1940s. These developments were done in collaboration with his Chief Engineer and Vice President of Engineering, Frank L. Stulen, who Parsons hired when he was head of the Rotary Wing Branch of the Propeller Lab at Wright-Patterson Air .

His company had made a number of manufacturing innovations in producing land mines, bombs, rockets, and helicopter rotor blades during World War 11. In 1947 he and Frank Stulen developed a method to produce contoured templets for checking blades by calculating successive machine positions on an IBM multiplier and then manually setting the .Their origins can be traced back to the 1940s and a man named John Parsons. Parsons was an engineer who initially started working for Sikorsky Aircraft building helicopter rotor blades, but when they started to fall, he knew he had to find a better solution to building them.Together, they were the first to use computer methods to solve machining problems, in particular, the accurate interpolation of the curves describing helicopter rotor blades. In the 1940s, a ‘computer’ meant a punch card-operated calculation machine.

REMEMBERING JOHN T PARSONS

metal tool box stanley

Our production range includes CNC processing center, automatic lathing, automatic milling, wire cutting, powder metallurgy processing and assembly of metal parts with plastic parts. We produce high quality custom cnc parts products and specialize in cold heading, threading, shaving, pointing, slotting, and grinding product to close tolerances .

cnc machine for helicopter rotor blades 1940|John T. Parsons History Project