what is the thickness range of sheet metal In Australia, the typical thickness of sheet metal is between 0.5 millimetres and 6 millimetres. Anything thicker 6 millimetres is classified as metal plate, and anything thinner than 0.5 . See more As you run to your bedroom searching for a possible priceless vintage metal lunch box, use this list to separate the valuables from the worthless.

0 · which thickness called sheet metal

1 · steel plate weight chart

2 · stainless steel sheet thickness chart

3 · sheet metal thickness chart wikipedia

4 · sheet metal specifications chart

5 · most common sheet metal thickness

6 · galvanized sheet metal thickness chart

7 · 304 stainless steel thickness chart

You will find many, however here are the common types of NEMA electrical enclosure: NEMA Enclosures. NEMA 1 Electrical Enclosure: Provide the least protection and are mostly used indoors. NEMA 2 Electrical Enclosures: The enclosures offer extra protection layer against light water drops.

Standard sheet metal thickness and size varies across different metals. Find standard sheet metal gauges and mm measurements in this article. See more

In Australia, the typical thickness of sheet metal is between 0.5 millimetres and 6 millimetres. Anything thicker 6 millimetres is classified as metal plate, and anything thinner than 0.5 . See moreIn the fabrication industry, ‘gauge’ is an identifier for the standard thickness of sheet metal of a specific material. The gauge size is based on the weight of the metal sheet and is inversely proportional to the thickness, which means the higher it is, the thinner the . See more

There are two ways to measure sheet metal: using a measuring tape (which is less precise) and a gauge wheel (more typically used in the industry). See moreYes, sheet metal thickness is important as it determines what kind of fabrication processes can be used. Thinner sheet metal is suitable for different processes and different . See more

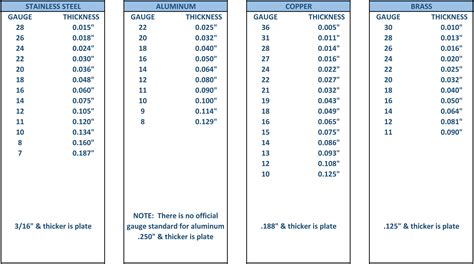

The chart below can be used to determine the equivalent sheet thickness, in inches . The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the . The term "gauge steel" is often used to refer to the thickness of sheet metal made of steel. Understanding these nuanced differences is vital when consulting a metal gauge chart to ensure that you're selecting the appropriate . To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar .

The gauge system, widely used in metal fabrication, provides a standardized method for specifying sheet metal thickness. For example, 3-gauge steel, commonly used in heavy-duty industrial applications, has a substantial .

Gauges indicate the material thickness of specific sheets. As gauge numbers increase, material thickness decreases.The chart typically lists a range of gauge numbers and their associated thickness values, allowing users to quickly determine the thickness of a specific sheet of metal. Gauges are used to signify the sheet metal thickness. A gauge conversion chart can be used to determine the actual thickness of sheet metal in inches or millimeters. For example, 18 gauge steel, according to a gauge conversion chart, is 0.0478 inch or 1.214 millimeter. The .

While we can measure sheet metal in inches, millimeters and mils, we can also find a metal’s thickness in relation to its weight per square foot. Metal gauges are identifiers for the relationship between thickness and weight.

For instance, if a project calls for a metal sheet that's around 0.040 inches thick, one can quickly refer to the gauge conversion chart and ascertain that this thickness aligns closely with 18-gauge aluminum. Standard Thickness for Automotive Sheet Metal. Automotive sheet metal comes in a range of thicknesses, and the choice depends on various factors such as the vehicle’s intended use, design requirements, and .When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the Specific thickness range. Spot weldments are best when welding material 0.20”-0.90” thick. Materials thicker than 0.90” aren’t suitable for a spot weld because the weldment won’t be strong enough, and welding can burn through materials thinner than 0.20”. . Approved Sheet Metal is here to help you choose the best welding technique .

To guard against people accidentally putting a hand into a machine, I’d use 1.5mm steel. If the metal is much thinner than this it may be difficult to weld or may distort in use. If the metal is much thicker than this it may be too heavy and unnecessarily expensive. If the guard is large, it may need thicker metal as it may distort as it is . Sheet metal is the next in line. The thickness of sheet metal starts from 0.5 mm and goes up to 6 mm. Anything above that is a metal plate. The thin sheet metal is easy to form, while still providing great strength. At a relatively cheap price, it makes a great fit for most engineering purposes. That is why we see it everywhere around us. we transform sheet metal into body panels for vehicles and structural components for buildings. With a typical thickness ranging from 0.5 millimeters to 6 millimeters, sheet metal is a choice material in the automotive industry for its lightweight yet sturdy characteristics, enhancing both efficiency and safety.

cnc machined shaft suppliers

Moving up to a 16-gauge stainless steel sheet, the decimal equivalent is 0.0595; The decimal equivalent of gauge numbers differs based on type of metal. Again, let’s use stainless steel as our example: A 14-gauge stainless steel sheet has a decimal equivalent of .0751. A 14-gauge carbon sheet has a decimal equivalent of 0.747.During the rolling process the rollers bow slightly, which results in the sheet metal being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances. . Thickness in. (mm . Architectural blueprints can call for a wide range of steel sheet and plate materials. These materials can vary in thickness—indeed, this measurement is what differentiates steel sheet from plate—depending on the application. . Ensuring Accurate Fabrications of Metal Sheet & Plate. The thickness of metal sheets and plates as required by . Metal gage is not a preferred method to specify thickness, even though it is commonly listed. The thickness associated with a particular gage value changes with the material specified. 22ga aluminum is not the same thickness as 22ga steel, and is not the same as 22ga zinc coated steel.

Sheet metal tolerance is a specified range that allows for variations in the design dimensions of parts. The manufacturing tolerances range defines the upper and lower limits of the variable design size of the workpiece. Tolerances are critical for ensuring the precision of sheet metal parts, and widely used in sheet metal fabrication . It's probably been mentioned before but sheet metal will always be thinner than the standard guage thickness specified. It almost always will be at the lower range of the tolerance. As it is sold by the pound and based on the pounds per square foot using the standard gauge thickness. So a 4x8 sheet will have a theoretical weight but will . When working with sheet metal, the term "gauge" is commonly used to describe the thickness or thickness range of the material. However, those unfamiliar with the gauge system may find it confusing to understand what is meant by a specific gauge, such as 18 gauge steel.

Multi-chapter guide to Perforated Sheet Metal describing: how perforated sheet metal is made, what perforated metal sheets are, metals used, types of. Editorial by Industrial Quick Search REQUEST FOR QUOTE. . High punching force . It is important to know that the gauge thicknesses also vary depending on the type of sheet metal being referenced. Take for instance 12-gauge thickness across the material types listed below; stainless steel is .Sheet Metal Material Thickness Range. Because sheet metal parts are manufactured from a single sheet of metal, the part must maintain uniform wall thickness. Sheet metal thickness ranges from 0.024 in. (0.609mm) to 0.250 in. .

When you assign a custom material to a sheet metal part, you can link the sheet metal parameters to the material. If you change the material, the sheet metal parameters also update. . Select Thickness Range. Click Add twice. For each row in the table, set the following: Row From < <= To Unit Bend Allowance Value; 1: 0 < <= 3: millimeters: K . I find that 19 gauge is a bit stiff to work with for general body work. I use 18 for floor panels, 20 for areas where a bit of extra stiffness is desireable, like fenders, and 22 to 24 for general body work.ASTM ANSI Mechanical Steel Sheet Mechanical Tolerances. Membership Services. Mechanical Steel Sheet Mechanical Tolerances. . CR - COLD ROLLED Sheet Metal Gage (guage) size chart Carbon Steel Sheets. Gage. Thickness, Inches. Lbs/Ft 2. Decimal Equivalent. Tolerance Range. Weight. H R . CR . 4 .2242 .2332.2152 . 9.375 . 5 .2092 Sheet metal thickness often has slight variations compared to its stated gauge thickness. For example, a 16-gauge cold-rolled steel sheet may have a stated thickness of 0.057", but the actual thickness can be around 0.056". These variations can impact tolerances, as a portion of the allowable tolerance is consumed just by the inherent thickness .

For example, a 14 gauge sheet of stainless steel is thicker than a 20 gauge sheet. Many sheet metal manufacturers utilize 8 gauge steel or thinner. If you get thicker steel than that, it is no longer referred to as sheet metal and instead is known as plate metal. The thickness of a luminum and other non-ferrous materials is measured in inches . thickness of sheet metal. Jump to Latest 4K views 2 replies 2 participants last post by Senkoboy Aug 17, 2014. S. Senkoboy Discussion starter. 48 posts What thickness is sheet metal? The thickness of sheet metal varies from 0.5 mm to 6 mm. When the thickness exceeds 6 mm, it is termed a metallic plate. The thickness of sheet metals being lower are easier to form. What are the sheet metal fabrication tools? There is a range of tools that are used by metal fabricators for sheet metal fabrication.

When it comes to ensuring the safety, durability, and aesthetics of your property, a reliable roofing and sheet metal service provider is essential. Sutter Roofing and Sheet Metal has built a strong reputation as a trusted provider of top-notch roofing solutions, including a wide range of sheet metal services. With years of experience in both. In this case, the equivalent sheet metal thickness is 0.035 inches or 0.88 millimeters. Remember that when it comes to sheet metal, the number 20 doesn’t directly tell you how thick the sheet is. You have to use a gauge chart to find out .What I do is check the "Override default parameters" on the sheet metal feature. Then, while in context of the assembly, I double click on the body. This will show your sheet metal dimensions (thickness, radius, and K factor for me). Then you can modify the thickness by double clicking it, and then link it to your assembly level custom property.

which thickness called sheet metal

Our dome arrays include, but are not limited to round domes, with superior life & tactile options available. We offer standard tactile metal domes & custom domes.

what is the thickness range of sheet metal|sheet metal thickness chart wikipedia