creo sheet metal tutorial pdf CREATE / BEND BACK / select the top surface as fixed plane / BEND BACK ALL / DONE / OK See more Used Metal Fabrication Equipment, From Used Press Brake, Punch Press, Metal Saws, Waterjet Machines & More, Call 844-262-6790

0 · sheet metal in creo parametric

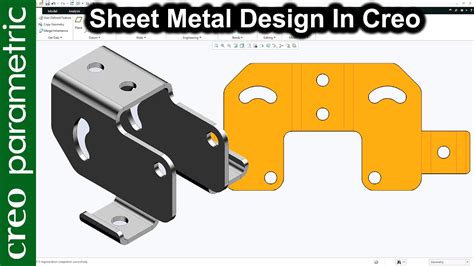

1 · sheet metal design in creo

2 · creo sheet metal practice drawing

3 · creo sheet metal drawing

4 · creo sheet metal basics

5 · creo practice sheet metal models

6 · creo parametric sheet metal tutorial

7 · creo convert to sheet metal

Automatics & Machinery has a large selection of used swiss & screw machines available from brands like Tsugami, Citizen, Star, KSI, Swistek, Ecomatic, Ganesh and more.

This pocket tutorial is intended to highlight the basic functionality of the sheetmetal module. Specifically, topics covered include: flat patterns, deformation allowance, bend tables, working in both flat and "as designed" states, and full associativity between part, drawing and flat state. Ensure you have the . See moreCREATE / UNBEND / REGULAR / DONE / select the top surface as fixed plane / UNBEND ALL / DONE / OK Observe the model in wireframe and shown axes . See more

can a junction box be buried

CREATE / CUT / DONE / select the top plane / DEFAULT ; sketch and align cut to axis as in following figure: Make the cut THRU ALL / OK 5. Add a sketched flat . See moreCREATE / BEND BACK / select the top surface as fixed plane / BEND BACK ALL / DONE / OK See moreFILE / OPEN / IN SESSION / select the flat state or SETUP / FLAT STATE / SHOW / select the flat state See more

Using Pro/SHEETMETAL, you can create parts in either their formed (bent) shape (Fig. SM.3) or the flattened shape. Once created, these parts can then be formed or flattened, as required. .

can 2 houses share electric box

Tutorial: Sheet Metal Layout By: Matthew Jourden Brighton High School Brighton, MI Minimum Required Views on a Sheet Metal Layout - Flat Pattern - Folded Pattern Views showing Bend . This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell . This method of working with sheet metal is to create a solid first then shell it before opening the sheet metal module. The alternative is to create the model within sheet metal from . In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange .

can a low voltage junction box be inside a wall

sheet metal tools including live flat pattern preview. • Creo Parametric will open native Solidworks, Inventor and Solid Edge models making it easy to reuse legacy data when upgrading to Creo. .

Creo Parametric comes with a feature called Sheet Metal. It is intended for creating enclosure designs to be manufactured from sheet materials such as steel etc. for machine bodies etc.SheetmetalusingCreoParametric4.0 Overview CourseCode TRN-5107-T CourseLength 16Hours Inthiscourse,youwilllearnhowtocreate sheetmetalpartsinCreoParametric.TheThis document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat .Ensure you have the sheetmetal module attached to your license of Pro/ENGINEER before beginning. 1. Create a part (sub-type sheetmetal) with extruded wall as first feature; sketch as in following figure: FEATURE / CREATE / WALL / EXTRUDED / DONE / ONE SIDE / DONE / select your planes etc.

Using Pro/SHEETMETAL, you can create parts in either their formed (bent) shape (Fig. SM.3) or the flattened shape. Once created, these parts can then be formed or flattened, as required. You can also use Family Tables to maintain the part in both states.

Tutorial: Sheet Metal Layout By: Matthew Jourden Brighton High School Brighton, MI Minimum Required Views on a Sheet Metal Layout - Flat Pattern - Folded Pattern Views showing Bend Angles - BOM Chart for Assemblies - NOTES Providing o Gauge o Material o Inside/Outside Bend Radius 1. Open Sheet Metal Model to be laid out 2.

This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell it before opening the sheet metal module. Create and name a new Sheetmetal part. This method of working with sheet metal is to create a solid first then shell it before opening the sheet metal module. The alternative is to create the model within sheet metal from a number of flat pieces joined together. 1. Create and name a new Part 2. Extrude a 200x100 rectangle 50 mm to give a solid and Shell from the top surface to 2mm 3.

sheet metal in creo parametric

sheet metal design in creo

In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall.sheet metal tools including live flat pattern preview. • Creo Parametric will open native Solidworks, Inventor and Solid Edge models making it easy to reuse legacy data when upgrading to Creo. • Faster assembly, real time interference detection and easier 3D sections.

Creo Parametric comes with a feature called Sheet Metal. It is intended for creating enclosure designs to be manufactured from sheet materials such as steel etc. for machine bodies etc.

creo sheet metal practice drawing

SheetmetalusingCreoParametric4.0 Overview CourseCode TRN-5107-T CourseLength 16Hours Inthiscourse,youwilllearnhowtocreate sheetmetalpartsinCreoParametric.TheThis document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat patterns, and create detailed drawings.Ensure you have the sheetmetal module attached to your license of Pro/ENGINEER before beginning. 1. Create a part (sub-type sheetmetal) with extruded wall as first feature; sketch as in following figure: FEATURE / CREATE / WALL / EXTRUDED / DONE / ONE SIDE / DONE / select your planes etc.

Using Pro/SHEETMETAL, you can create parts in either their formed (bent) shape (Fig. SM.3) or the flattened shape. Once created, these parts can then be formed or flattened, as required. You can also use Family Tables to maintain the part in both states.

Tutorial: Sheet Metal Layout By: Matthew Jourden Brighton High School Brighton, MI Minimum Required Views on a Sheet Metal Layout - Flat Pattern - Folded Pattern Views showing Bend Angles - BOM Chart for Assemblies - NOTES Providing o Gauge o Material o Inside/Outside Bend Radius 1. Open Sheet Metal Model to be laid out 2. This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell it before opening the sheet metal module. Create and name a new Sheetmetal part.

This method of working with sheet metal is to create a solid first then shell it before opening the sheet metal module. The alternative is to create the model within sheet metal from a number of flat pieces joined together. 1. Create and name a new Part 2. Extrude a 200x100 rectangle 50 mm to give a solid and Shell from the top surface to 2mm 3. In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall.sheet metal tools including live flat pattern preview. • Creo Parametric will open native Solidworks, Inventor and Solid Edge models making it easy to reuse legacy data when upgrading to Creo. • Faster assembly, real time interference detection and easier 3D sections.

Creo Parametric comes with a feature called Sheet Metal. It is intended for creating enclosure designs to be manufactured from sheet materials such as steel etc. for machine bodies etc.

SheetmetalusingCreoParametric4.0 Overview CourseCode TRN-5107-T CourseLength 16Hours Inthiscourse,youwilllearnhowtocreate sheetmetalpartsinCreoParametric.The

can a electrical junction box be installed in an attic

can an electrical box fit in a fglat framed wall

DMG MORI DURA VERTICAL ECO 1035 CNC VERTICAL MACHINING CENTER. 9058. X - Axis Travel: 40.7" Y - Axis Travel: 22" Z - Axis Travel: 20.1" Spindle Speed: 12,000 RPM. Spindle Taper: 40. 9058. View Details. DMG MORI NVX 5100 / 50 CNC AXIS VERTICAL MACHINING CENTER. 9654. X - Axis Travel: 41.3"

creo sheet metal tutorial pdf|creo parametric sheet metal tutorial