best metal for bracket Below is shown 2 metal part designs, both are of the same thickness but the first part will be significantly stronger due to the gusset (small triangular piece) welded on the bracket. This is a . There are many different types of metal fabrication processes, each with its own set of benefits and drawbacks. The most popular methods are cutting, casting, welding, stamping, and forging. The best method for fabricating metal will depend on .

0 · what is a metal bracket

1 · types of metal brackets pdf

2 · sheet metal bracket examples

3 · sheet metal bracket designs

4 · metal support brackets

5 · metal brackets for construction

6 · different types of metal brackets

7 · aluminum metal brackets

The most common screw size for electrical boxes is a 6-32 flathead screw. However, for heavier applications like ceiling lighting and fans, an 8-32 screw is more suitable. Ground screws in electrical boxes are typically 10-32 and must be painted green for visibility and to meet electrical codes.

In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, . The use of sheet metal in crafting brackets offers excellent durability, versatility, and cost-effectiveness, ensuring robustness in various application scenarios, from mounting . But how do you go about creating a sheet metal bracket? 3ERP has years of expertise in sheet metal prototyping, and this guide explains the basics of sheet metal brackets, including common bracket types, bracket .

Below is shown 2 metal part designs, both are of the same thickness but the first part will be significantly stronger due to the gusset (small triangular piece) welded on the bracket. This is a .Find Steel angles, brackets & braces at Lowe's today. Shop angles, brackets & braces and a variety of hardware products online at Lowes.com..88.45

what is a metal bracket

.68.88 When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape.Find models with galvanized 12- and 18-gauge steel that resists corrosion. From metal corner brackets to mending braces, you’ll find everything you need for your next project at Lowe’s. These Angles, Brackets & Braces are the most popular .

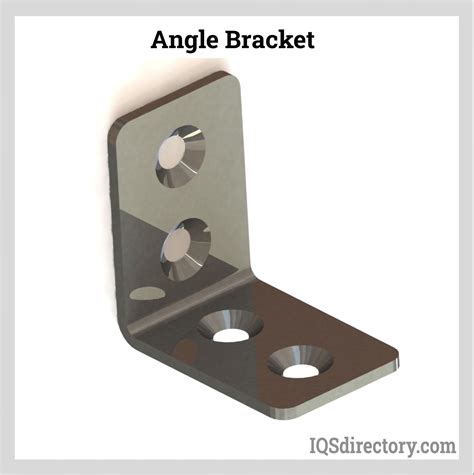

Metal brackets are supportive structures that link, provide support, and reinforce two or more structures. They can act as either intermediate or final structures. This guide explores all the fundamental facts about the custom .

types of metal brackets pdf

In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, and share tips to help you design the ideal custom brackets for your applications. The use of sheet metal in crafting brackets offers excellent durability, versatility, and cost-effectiveness, ensuring robustness in various application scenarios, from mounting heavy equipment to supporting shelves.

The choice of metal for producing metal brackets influences their intended use. Metals like bronze, brass, and copper are ideal for decorative brackets, while steel, stainless steel, titanium, and certain aluminum alloys are suited for industrial applications.

But how do you go about creating a sheet metal bracket? 3ERP has years of expertise in sheet metal prototyping, and this guide explains the basics of sheet metal brackets, including common bracket types, bracket design tips, and the best sheet metal bracket materials.Below is shown 2 metal part designs, both are of the same thickness but the first part will be significantly stronger due to the gusset (small triangular piece) welded on the bracket. This is a nice feature for keeping the profile of the bracket small yet creating a strong bracket.

Find Steel angles, brackets & braces at Lowe's today. Shop angles, brackets & braces and a variety of hardware products online at Lowes.com. When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape.Find models with galvanized 12- and 18-gauge steel that resists corrosion. From metal corner brackets to mending braces, you’ll find everything you need for your next project at Lowe’s. These Angles, Brackets & Braces are the most popular among Lowe’s entire selection.

custom metal fabrication knoxville

Metal brackets are supportive structures that link, provide support, and reinforce two or more structures. They can act as either intermediate or final structures. This guide explores all the fundamental facts about the custom metal bracket fabrication process. Choosing the right tools for making sheet metal brackets is essential. One survey found that using a combination of traditional and modern tools can increase efficiency by up to 40%. Having the proper equipment will ensure that your work is accurate and precise.

In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, and share tips to help you design the ideal custom brackets for your applications. The use of sheet metal in crafting brackets offers excellent durability, versatility, and cost-effectiveness, ensuring robustness in various application scenarios, from mounting heavy equipment to supporting shelves.The choice of metal for producing metal brackets influences their intended use. Metals like bronze, brass, and copper are ideal for decorative brackets, while steel, stainless steel, titanium, and certain aluminum alloys are suited for industrial applications.

But how do you go about creating a sheet metal bracket? 3ERP has years of expertise in sheet metal prototyping, and this guide explains the basics of sheet metal brackets, including common bracket types, bracket design tips, and the best sheet metal bracket materials.Below is shown 2 metal part designs, both are of the same thickness but the first part will be significantly stronger due to the gusset (small triangular piece) welded on the bracket. This is a nice feature for keeping the profile of the bracket small yet creating a strong bracket.Find Steel angles, brackets & braces at Lowe's today. Shop angles, brackets & braces and a variety of hardware products online at Lowes.com. When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape.

custom metal fabrication china

Find models with galvanized 12- and 18-gauge steel that resists corrosion. From metal corner brackets to mending braces, you’ll find everything you need for your next project at Lowe’s. These Angles, Brackets & Braces are the most popular among Lowe’s entire selection. Metal brackets are supportive structures that link, provide support, and reinforce two or more structures. They can act as either intermediate or final structures. This guide explores all the fundamental facts about the custom metal bracket fabrication process.

sheet metal bracket examples

You don’t need a junction box for all outdoor light fixtures. You can screw in incandescent and LED bulbs directly into the power outlet – no junction box needed. However, some light fixtures, such as those with metal halide .

best metal for bracket|metal support brackets