mostly printed cnc metal aftermarket parts I've had success using ABS for machine tooling and lightweight CNC builds. It holds up better than PLA at the kinds of temperatures stepper motors get to. But more of a bugger to print as an ambient temp of ~30oC while printing helps stop warping. Alternatively, you may get away with PETG. But I've not built anything with it yet.

Let us introduce ourselves! WUKO Products are known for their high quality, .

0 · mostly printed cnc upgrades

1 · mostly printed cnc review

Before you paint or replace entirely, give your kitchen cabinets a new lease on life by wrapping them with an architectural vinyl finish from RM wraps. Shop hundreds of designs in wood grain, leather, stone, metallic, and fabric styles from big-name brands like 3M, LG, and Belbien.

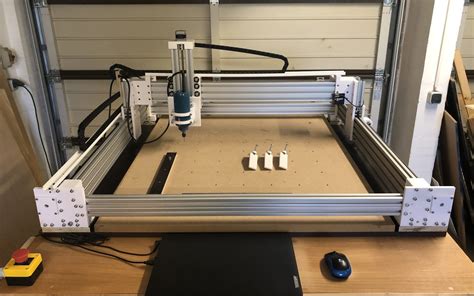

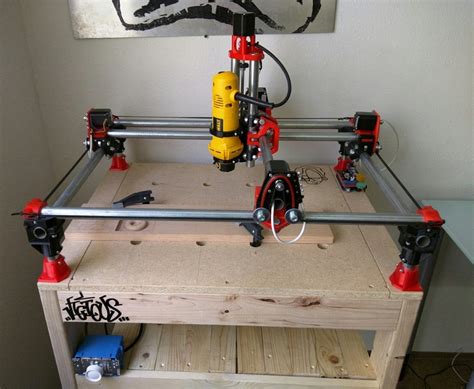

We’re building a MPCNC! You can find the parts I used listed below, as well as the build videos and livestreams. As the build goes on, this page will get updated! Parts used The Mostly Printed CNC is famous for two things. First, being made mostly from 3D printed parts and commonly available steel tubing. Second, because of the materials used, its.

Plus it's all metal hardware, better for milling than 3d printed parts. Edit - I forgot to mention that I built an mpcnc about 3 years ago. It worked, but I wouldn't build another.Another option is an MPCNC (mostly printed). You still need to buy a dremel or router (those can usually be acquired pretty cheaply second hand) but it’s a really good platform to learn on and would give you a much larger working area to allow you to make signs and other objects. I am on a new project now. A MPCNC - mostly printed cnc. . around the 1500$ mark (with a 2.2kw spindle/VFD) and expect to be around the 2000$ mark when done I did a plasma with 3d printed parts, and found the same problems, tolerances, . Then tried grblHAL on a custom board from on the folks on the Discord. I had lots of trouble getting it .

I've had success using ABS for machine tooling and lightweight CNC builds. It holds up better than PLA at the kinds of temperatures stepper motors get to. But more of a bugger to print as an ambient temp of ~30oC while printing helps stop warping. Alternatively, you may get away with PETG. But I've not built anything with it yet.Posted by u/SchwiftySkidgy - 991 votes and 58 comments The Mostly Printed CNC is, as the name suggests, an open-source machine made from (mostly) 3D printed parts. This evolved from the RepRap project , a project to develop the first-ever self-replicating 3D printer, started by Dr Adrian Bowyer at Bath University in .

My open-source, mostly printed magnetic toolchanger mechanism is finally printing properly and the files are now released on Github! Locked post. New comments cannot be posted.How do people get custom metal parts for their projects, they can’t be spending hundreds of dollars on fairly small parts—can only imagine the cost of large parts. . wages (either for an employee or the owner) for programming and running the part - it all adds up. In the CNC world things start to get cheaper once you need multiples, a lot . We visited Detroit Speed and found that newer technologies, including 3D printed metal parts, are used in almost all of their builds these days. . CNC machining is still the go-to for custom .

Yes, ball screw and linear rail protection is a consideration, you can cheaply get expanding baffles to cover both from Ali. If you're mainly working in wood however very a quick dust off after use is fine. If you're intending to mostly work in metal protecting .

mostly printed cnc upgrades

Posted by u/Man_of_Many_Hats - 16 votes and 33 comments422K subscribers in the functionalprint community. A community dedicated to share and discuss 3D prints that have a specific, practical function or. CNC machines normally take less time to install whereas the X-carve takes a little longer to install due to its add-ons. Mostly printed CNC machines are a little cheaper as they do not have the facility to use add ons. .5.6K subscribers in the diycnc community. The home of building, modifying, and converting CNC machines of all shapes and sizes.

A Mostly Printed CNC machine from Vicious1 provides an easily configured platform for low-force CNC activities like plotting, vinyl cutting, PCB milling, and maybe wood / plastic / wax routing with a suitable dust vacuum / downdraft table / enclosure. Despite many videos, the notion of open-air laser cutting remains a non-starter around here.. I opted for the Parts Bundle (all .I'm not looking for depth and quality like in a standard currency coin. Mostly just looking to engrave a picture in one layer. Nothing complex. A simple clip Art style design. There are no shortage of CNC style machines claiming to laser engrave, I am just wondering if anyone has any ideas or experience in dealing with these.

/r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices. Members Online I need some advice on what 3D printers to buy to create a well .

A guy I worked with ordered some parts from China. From what he said you have to be really careful because 90% of companies are either scams or will try to give you shit parts. How to Build a Custom 3D Printed CNC - DIY Complete BuildOutline: This video highlights how I built a custom 3D printed CNC machine for about 0. This rou.24 votes, 13 comments. 53K subscribers in the hobbycnc community. A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve.Watch. Shop. Explore

Compact DIY CNC (Mostly Metal) 0 reviews . 6. PWBdesigns @PWBdesigns_213536 . It uses hgr15 linear rails and sfu1204 ball screws. All the parts can be sourced for approximately 1000$. This was inspired by the printNC, however it is more compact and cheaper. Tags. . Mostly 3D printed CNC 3018 DIY . 51. 0. 412. Mostly Printed CNC QR Toolmount . Metal 3D printing and CNC machining have their unique strengths and limitations that can significantly impact the performance of the manufactured metal parts. Metal 3D Printing: Metal 3D printing is capable of making parts with complex geometries. Metal 3D printed parts can exhibit anisotropy—meaning their strength and mechanical properties .

mostly printed cnc review

Shop our aluminized fabrics for high-performance options. Our metalized film and foil-backed textiles protect against high-heat environments or equipment.

mostly printed cnc metal aftermarket parts|mostly printed cnc upgrades