groove in sheet metal V-grooving can reduce the material thickness at the bend line by half, from 0.080 to 0.040 in., which allows for a clean, tight bend radius. Nevertheless, thinning the material reduces the distance from the outside . In this post, we’ll discuss the various types of electrical boxes and their uses so you can make an informed decision about your next electrical project. 1. Round Pan Electrical Box. Round pan electrical boxes are circular and are commonly used for ceiling fixtures such as chandeliers, pendant lights, and smoke detectors.

0 · v grooving machine sheet metal

1 · v grooving in sheet metal

2 · stainless steel sheet grooving machine

3 · sheet metal v groover thickness

4 · sheet metal grooving methods

5 · sheet metal grooving machine

6 · sheet metal grooving knives

7 · sheet metal groover depth

The splitter boxes are designed for distribution of up to 600 V (max) service using either 3 or 4 wires. Formed 14 and 16 gauge steel. Factory installed splitter blocks. Smooth, continuously welded seams ground smooth.

V-grooving can reduce the material thickness at the bend line by half, from 0.080 to 0.040 in., which allows for a clean, tight bend radius. Nevertheless, thinning the material reduces the distance from the outside .

What is the use of groover in sheet metal work? A groover, also known as a V groover or V grooving machine, is a tool used to scribe and slot V-shaped grooves into metal . V-grooving involves cutting a groove along the bend line. You can compensate for springback by adjusting the angle of the V-groove. So, how exactly do we apply them? Last month I described the advantages, which include ease of forming and dimensional accuracy, and disadvantages, which include the low strength of a V-groove bend. This month I’ll cover exactly how to perform V . Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes.

Groove seam joint. Form the edges of two pieces into open hems that can subsequently be joined to create this type of joint. It is reminiscent of two hands locking fingers together. Sometimes known as lock seams, they can speed up .Essentially, V Grooving technology revolves around creating precise, pre-programmed cuts in metal sheets. These cuts, or grooves, follow a predetermined 'V' shape, which is essential for subsequent metal bending and forming .

V-grooving is a technique used in metal fabrication to create precise bends in sheet metal. It involves cutting grooves along the bend line, which allows for small outside bend radii and accurate dimensional results. Here's how you can .The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a HAND GROOVER (fig. 2-58). When making a .

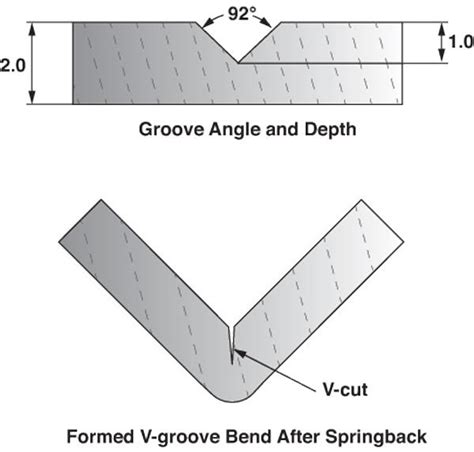

Manual sheet metal grooving toolDon't forget to Subscribe

V-Grooving & folding of sheet metal for lift manufacturers, joinery and fit-out companies Creating precise, sharp angles and folds with V-Grooving machinery Bending metal using a V-Grooving machine allows it to be folded to a tight . Buy 6-60mm Step Drill Bit, 12.5mm/0.5” Shank 4241 HSS Spiral Groove Drill Bit for Wood, Plastic, Sheet Metal: Step Drill Bits - Amazon.com FREE DELIVERY possible on eligible purchases Skip to main content . 1-3/8" Black Cone Drill Bits for Steel Metal Sheet Hole Drilling Cutting, Multiple Hole Sprial Unibit, Stepped Up Bits Home Tools. When slotting the sheet metal bending V groove size, the groove can be rationalized according to the required bending angle of the workpiece. Generally, the angle of the V-groove is 1-2° larger than the bending angle. For example, when we bend one workpiece to be 90°, the V-groove angle usually will be slotted to 92°, so that the caused .

T-Groove® Metal Wall Panels, Fascia, Soffit, And Ceiling Panels. T-Groove® will give your building a bold and distinct design. It's a versatile metal panel system that's designed so that you can choose the gap between each sheet. It's available in no reveal, 1, 2, or 3 inch reveals. You can even mix and match the different sizes. Buy NordWolf HSS Titanium Step Drill Bit, Spiral Groove Double Flute Multiple Hole Unibit for Sheet Metal, 10 SAE Step Sizes 1/4" to 1-3/8": Step Drill Bits - Amazon.com FREE DELIVERY possible on eligible purchases. . Anfrere 10 Sizes Step Drill Bit for Metal Sheet, 1/4 to 1-3/8 Inches High Speed Steel Drill Cone Bits for Hole Drilling .LM 135. SuperSoft® Door seals. '84-'88 Toyota 4-Runner & pick-up trucks Excellent Quality. Posted by Henry Gildersleeve on 19th Oct 2018 Fit perfectly. Metal sheet CNC V-grooving machine is often used in architectural decoration industry, which can groove stainless steel sheet, aluminum sheet and other metal sheets in V-shape, so that the arc radius of the edge of the workpiece after bending is extremely small, and the bending force required for bending sheet is reduced. It can also be used to pre-position the .

Here we explore six methods to add structure to sheet metal, helping ensure your project posseses both strength and functionality. Bending Bending is just what it sounds like – creasing a sheet of metal to achieve a curved or angular shape. This process is commonly used in forming various components such as brackets, flanges, or panels in .Groove seam joint. Form the edges of two pieces into open hems that can subsequently be joined to create this type of joint. . The raw and flange corner joint is a type of sheet metal joint that closely resembles a plain lap joint and involves a flat stock piece joined to a 90-degree bend to form the corner. To join the two pieces, overlap .Multiply 1/8 by 2 1/2 and your answer will be 5/16 inch, which you will allow when laying out sheet metal for making the wire edge. Joints. The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal.sheet metal quiz 4. Share. Students also viewed. Organic & Fluency Disorders Chapter 13. 30 terms. lovingangell. Preview. Ch 36 & 37 quiz review . Teacher 28 terms. Dayana143546. . collars used with HI-LOK fasteners have a _____ break off groove which shears off at a predetermined _____, leaving the lower portion of the collar seated with .

2833 Huffman Blvd. Rockford, Illinois 61103 USA Phone: (815) 962-3011 Fax: (815) 962-2227 [email protected] have tongue and groove roof decking that appears to be in good shape from what I can see in the attic and garage. It is spaced tightly and had no gaps or Splits. I am getting my roof replaced and I have heard conflicting options from .

Download and print in PDF or MIDI free sheet music of The Rumbling - Sim for The Rumbling by Sim arranged by shrihanmahara for Drum group (Solo) But without a proper way to secure the sheet metal to the machine table, the V-groove depth was difficult to control and extremely inefficient. More recently shops have relied on CNC grooving machines designed for the task. Chapter #6 – Sheet Metal Seams. Seams run longitudinal along the length of the duct run, while joints run transverse (across). Seams run parallel to the air flow, while joints are perpendicular to the air flow. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces together.Our V-Groove soffit panels are roll formed to offer design flexibility and economical fabrication. Call: (847) 478-8500

#VGroovingMachineforSheetMetal#VGrooveMachineformetal #StainlesssteelVGroovingMachineManufacturers:KRRASS(China)Manufacturer .

v grooving machine sheet metal

HSS Spiral Groove Step Drill Bit, 12 Steps High-Speed Steel 1/4" to 2-3/8", Large Step Drill Bits for Cutting Holes in Stainless Steel Aluminum Sheet Plastic Wood . Stepped Up Bits & Automatic Center Punch for Sheet Metal, DIY Lovers with Aluminum Caes, Total 50 Sizes for Multiple Hole.The main equipment of v-groove bending technology is press brake and sheet metal V-groover (also been called V-grooving machine). The press brake is a traditional plate bending machine, and the thin plate V-grooving machine is a new type of sheet metal processing machinery, which is the key equipment of V-cut bending technology.

Constrained groove pressing (CGP) is a modern technique for developing ultrafine grain structures in sheet metals for inducing superior material properties. In CGP, the sheet metal specimens are subjected to repetitive corrugating and straightening under the plane strain deformation condition by utilizing alternate pressing with the asymmetrically grooved dies and .It is widely used in the sheet metal V-groove, U-groove, and other irregular groove processing, which is including stainless steel plate, ordinary steel plate, aluminum plate, copper plate, composite plate under 4mm before bend forming. The V grooving machine includes vertical V groover machines and horizontal V groover machines.Tongue and Groove detail (Image Courtesy: piterest) It is very convenient to adapt tongue and groove joints for detaching sheet metal parts from one another using tongue and groove systems. A tongue designed at the end of a component gets inserted into a groove of another component with a slight play.

RE: Machined Groove In Sheet Metal mfgenggear (Aerospace) 26 Mar 12 14:55 Mike's Statement is correct, Punching will be half sheared & half tear in the material, a fine blanking die can be improved but will have sharp burrs,a secondary punch can improve the holes.

Sheet metal V-groove machine is a professional equipment used to process sheet metal workpieces. By cutting V-grooves on the sheet metal, it can be bent into the desired shape at a specific position. This technology is widely used in the sheet metal processing industry, providing an efficient and precise solution for the bending and processing .

custom metal fabrication fort collins

Weatherproof junction boxes, as the name suggests, are designed to withstand exposure to harsh weather conditions. These boxes are typically made of durable materials, such as polycarbonate or aluminum, and feature a gasket or seal to provide a watertight enclosure.A.) junction boxes are used as support for devices and lighting as well as protection for wires and terminals. It will contain the arc blast that could occur during fault. A.) what are junction boxes used for? B.) are junction boxes .

groove in sheet metal|v grooving in sheet metal