how bend sheet metal Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with. With the NEW Ashley J501 Junction Box, these obstacles can be overcome. 1. Easy to use. 2. Wide application suitability. 3. Compliance with latest regulations. The clamps secure cables in .

0 · types of sheet metal bends

1 · types of sheet metal benders

2 · sheet metal bending dies

3 · sheet metal bend tolerance chart

4 · sheet metal bend allowance chart

5 · maximum thickness sheet metal bending

6 · bend sheet metal at home

7 · bend allowance in sheet metal

Forged metal tends to work. Even actual welding of the non-JB variety isn’t likely to work well in this case, goops and putties are a funny diversion but there’s just no chance.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.

soldadura metalica en frio nural 21

Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with. Simple sheet metal bender using a hand roller, clamps and plywood.Music: Monkeys Spinning Monkeys by Kevin Macleod. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges -Types of hand seamers Sign up for the email list.

solidworks bend part not sheet metal

You can do a lot with only a handful of tools. Even still, it can be pretty easy to mangle if you don’t use the right technique. Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working .Sheet metal bending has distinct advantages over alternative sheet metal fabrication processes, including higher output, lower cost and high flexibility in design. It also removes many difficulties associated with assembly techniques .Mark a bend line and place the sheet metal on the edge of your bench. Next place the wood parallel and slightly behind the bending line. Clamp the wood on top of the metal to the workbench. Finally, bend the sheet up by hand to the angle desired. If you want a sharp 90° bend, tap along the crease with a mallet. CuttingAnd that includes scrap metal I came across on the farm. But this involves bending barn tin metal pieces into shape for the hood, which reminded me of a common question: How do you bend sheet metal without a bending brake? I .

soldadura en frio para metal mexico

Bend features can join sheet metal faces that do not touch. When you select edges on sheet metal features, you add material to the model using the bend radius and material thickness defined by the sheet metal style. Faces extend in compliance with your default (or selected) bend radius. If the faces are parallel, but not coplanar, you can add a .

While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more.Step #5 Clamping the Sheet Metal. After measuring and marking the bend line, the next step is clamping the sheet metal. Here are the key actions to take in this phase: Position the Sheet Metal: Place the sheet metal in the bending machine or workbench, aligning it with the bend line. On top of that, accurate positioning ensures a precise bend. Get Ready to Bend: Before putting the sheet metal into a vise, first mark your bend lines with a pencil, and then cut the sheet so that at least ¼” of extra room is left over. Finally, make sure the sheet is filed down smoothly, because otherwise you may get cracks in the metal.I'm trying to bend 12"x1" strips of mild steel (1.2mm or if that's too thick 0.9mm) horizontally (i.e. so I have 2 faces that are 12"x0.5" wide). I was thinking of walking it along the edge and then finishing the bend with a hammer against an iron angle. I can't seem to get enough leverage any other way. Is the bend formed using that tool crisp?

Q: What is the right approach to finding the bend radius of a sheet metal component? A: The bend radius for a piece of sheet metal is determined by factors such as the material type, thickness, and intended bend angle. Proper consideration of the bend radius avoids cracks on the metal and ensures that the required bend quality is achieved.

Learn autodesk inventor tips and trick how to bending sheet metalYou can check our channels about cad below:MufasuCAD : https://www.youtube.com/user/CADtutor.

Sheet Metal Bending Calculator. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into:Metal bending and forming is a necessary skill for anyone who work at a body shop or works on cars at home as a hobby. Learn about the techniques and tools here. . How to Bend Sheet Metal : The Basics. Whether you run your own auto body shop or fix up cars in your free time, knowing the basics of metal bending, forming, and shaping is a must .

types of sheet metal bends

types of sheet metal benders

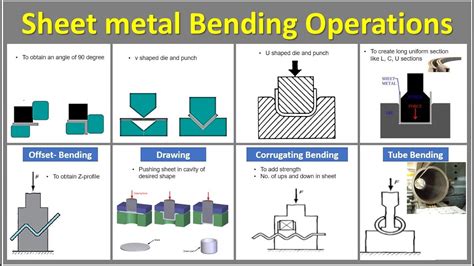

Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic deformation. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

How to design bend reliefs for sheet metal with CAD software. There are two common ways to add bend relief to your design. One way is to do it manually. This is an option in any tool you use to create your design. The .

sheet metal bending dies

Bend Allowance Chart. The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending . (A press brake is a simple machine employed in sheet metal bending processes, it forms desired bends on the sheet by working to clamp the sheet metal in position for press between the punch and the die) Roll Bending. .The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” When a flat piece of material is bent the inside face of the bend is compressed and the outside part stretches.

Sheet Metal Box: This is a great project to make if you are new to working with sheet metal. At this point in my class all of our sheet metal projects have been very simple with, at most, one bend. But, when we get to the this project my students always have a hard.

Simple sheet metal bender using a hand roller, clamps and plywood.Music: Monkeys Spinning Monkeys by Kevin Macleod In this Fusion 360 Tutorial I cover how to use the Bend feature. It is a really simple tool that can make modeling sheet metal vary simple. *These Fusion 360.

While those in the sheet metal trade form dozens of different kinds of hems and seams, most are simply outdated, and only three are in general use. . As the punch tip applies force to the bend line and forms the workpiece, the metal elongates by one bend deduction; we account for half of that elongation in front of the bend line and the other . Bending sheet metal also allows you to create clean and accurate bends that enhance the aesthetic appeal of the finished product. Bending 16 Gauge Sheet Metal Vs. Other Gauges Compared to other gauges, bending 16 gauge sheet metal requires more force and pressure. However, it also provides more durability and strength.Plasma cutting bend relief cuts for hand bending sheet metal. I'm an absolute 100% newbie to CNC plasma cutting, CAD, and solidworks. I tried Freecad, and Fusion 360, but Solidworks feels like it has just "clicked" for me, particularly with 3D parts, which is what most of my needs are. I've designed a few sheet metal parts, and I'm enjoying .

Sheet metal bending is a manufacturing process that deforms flat metal sheets into desired shapes with force. The process uses tools like punches and dies. Commonly, laser-cut sheet metals are bent using press brakes or benders. What is the difference between air bending and bottom bending?

A sheet metal brake is the best tool for bending sheet metal. 2. Use the Right Technique: Apply steady pressure while bending the sheet metal. Avoid applying too much pressure, as this can cause the sheet metal to crack or break. 3. Practice: Bending sheet metal is a skill that takes time to master. Practice on scrap pieces of sheet metal . 4 Sheet Metal Bend Gains FAQ. 4.0.1 What is a sheet metal bend gain, and why is it important in sheet metal fabrication? 4.0.2 Why should design engineers be concerned about sheet metal bend gains? 4.0.3 Do design engineers need to calculate sheet metal bend gains themselves? 4.0.4 How can I accurately calculate sheet metal bend allowances or .

soldadura de metales no ferrosos

solidworks 2019 sheet metal

Yes, upgrading your breaker box can potentially lead to reduced electric bills, but it’s not a direct cause-and-effect relationship. A newer and more efficient breaker box can improve energy .

how bend sheet metal|bend allowance in sheet metal