cnc automatic feeding machine suppliers Whether you need a vibrating feeder, an automated conveying system, an engineered automation equipment solution, or need to explore our comprehensive lines of bulk feeders, bar feeders and flex feeders, you find . Ubbink guarantee the well-being of occupants by offering high quality and premium ductwork systems that distribute fresh air and extract moist air from the habitable rooms of residential buildings. Ubbink ductwork connects flawlessly .

0 · industrial automation feeders

1 · flex feeders for sale

2 · feedall flex feeders

3 · bar feeder machine

4 · automatic lathe feeders

5 · automatic bar feeders

The Ubiquiti Camera Junction Box provides a robust and secure mounting solution for your UniFi Bullet, Dome, and Turret cameras. The tamper-resistant design discourages unauthorized access and safeguards your camera and its cabling.

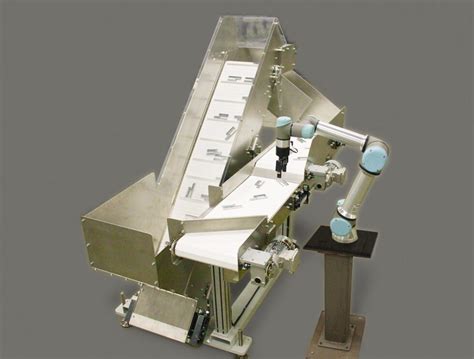

Complete Solutions for Part Feeding, CNC Machine Tending, and More. Feedall Automation is the leading provider of automated feeding systems for manufacturers around the world. We offer a .Simple to install, bar feeders serve as a cost-effective automation solution and perform repetitive, time-consuming tasks that make them invaluable in many shop environments—especially amidst labor shortages and increased part demand. .

Bar feeding automation works for manufacturers making turned parts in volume. Most CNC lathes , screw machines and Swiss-style turning machines can accept a bar feeder. Applications include hydraulic components, couplings, specialty .Industries as diverse as aerospace, automotive, medical, industrial equipment and consumer goods can all benefit from bar feeders. A bar feeder will mount to almost any CNC lathe, screw machine or Swiss-style turning machine. Bar .Whether you need a vibrating feeder, an automated conveying system, an engineered automation equipment solution, or need to explore our comprehensive lines of bulk feeders, bar feeders and flex feeders, you find .

Automatic feeding CNC lathe is a fully automatic CNC lathe independently developed, designed, manufactured and sold by Taian Haishu Machinery Co., Ltd. This automatic feeding CNC lathe is equipped with a pneumatic .Eliminate manual operations and increase your productivity by adding an automatic bar feeder to your Modern Automatic Cut-Off Machine—or any other machines that require feeding of .Complete Solutions for Part Feeding, CNC Machine Tending, and More. Feedall Automation is the leading provider of automated feeding systems for manufacturers around the world. We offer a comprehensive line of high quality and highly customizable automation solutions designed to increase your production uptime and improve operational efficiency.

Simple to install, bar feeders serve as a cost-effective automation solution and perform repetitive, time-consuming tasks that make them invaluable in many shop environments—especially amidst labor shortages and increased part demand. Ready to jump into automation? Contact us. Compatible Okuma Products: Partner Solutions:Bar feeding automation works for manufacturers making turned parts in volume. Most CNC lathes , screw machines and Swiss-style turning machines can accept a bar feeder. Applications include hydraulic components, couplings, specialty washers, nuts, bolts and screws — as well as watch and machine parts.Industries as diverse as aerospace, automotive, medical, industrial equipment and consumer goods can all benefit from bar feeders. A bar feeder will mount to almost any CNC lathe, screw machine or Swiss-style turning machine. Bar feeders excel in .

Whether you need a vibrating feeder, an automated conveying system, an engineered automation equipment solution, or need to explore our comprehensive lines of bulk feeders, bar feeders and flex feeders, you find high-quality equipment built to .

industrial automation feeders

Automatic feeding CNC lathe is a fully automatic CNC lathe independently developed, designed, manufactured and sold by Taian Haishu Machinery Co., Ltd. This automatic feeding CNC lathe is equipped with a pneumatic manipulator, a pneumatic pusher and a workpiece magazine.Eliminate manual operations and increase your productivity by adding an automatic bar feeder to your Modern Automatic Cut-Off Machine—or any other machines that require feeding of random-length tubes and bars, such as Cold Saws and third party CNC Lathes.We specialize in bar feeding and material handling of long and heavy parts and complete CNC tool integration efforts to provide automated solutions to non-standard applications. Double sided system allows bars to full length of the bar to pass through the CNC machine tool. Also allows multiple passes.CNC automatic feeding machines are a type of CNC machine that automates the process of feeding raw materials into the machine for processing. This not only saves time and labor costs but also ensures consistent and accurate feeding of materials, leading to improved product quality and reduced waste.

One vital niche within the vast domain of CNC technology is the CNC automatic feeding machine. This article dives into the world of CNC automatic feeding machine manufacturers, exploring their products, their uniqueness, and what makes them industry leaders.Complete Solutions for Part Feeding, CNC Machine Tending, and More. Feedall Automation is the leading provider of automated feeding systems for manufacturers around the world. We offer a comprehensive line of high quality and highly customizable automation solutions designed to increase your production uptime and improve operational efficiency.

Simple to install, bar feeders serve as a cost-effective automation solution and perform repetitive, time-consuming tasks that make them invaluable in many shop environments—especially amidst labor shortages and increased part demand. Ready to jump into automation? Contact us. Compatible Okuma Products: Partner Solutions:

Bar feeding automation works for manufacturers making turned parts in volume. Most CNC lathes , screw machines and Swiss-style turning machines can accept a bar feeder. Applications include hydraulic components, couplings, specialty washers, nuts, bolts and screws — as well as watch and machine parts.Industries as diverse as aerospace, automotive, medical, industrial equipment and consumer goods can all benefit from bar feeders. A bar feeder will mount to almost any CNC lathe, screw machine or Swiss-style turning machine. Bar feeders excel in .Whether you need a vibrating feeder, an automated conveying system, an engineered automation equipment solution, or need to explore our comprehensive lines of bulk feeders, bar feeders and flex feeders, you find high-quality equipment built to .Automatic feeding CNC lathe is a fully automatic CNC lathe independently developed, designed, manufactured and sold by Taian Haishu Machinery Co., Ltd. This automatic feeding CNC lathe is equipped with a pneumatic manipulator, a pneumatic pusher and a workpiece magazine.

Eliminate manual operations and increase your productivity by adding an automatic bar feeder to your Modern Automatic Cut-Off Machine—or any other machines that require feeding of random-length tubes and bars, such as Cold Saws and third party CNC Lathes.We specialize in bar feeding and material handling of long and heavy parts and complete CNC tool integration efforts to provide automated solutions to non-standard applications. Double sided system allows bars to full length of the bar to pass through the CNC machine tool. Also allows multiple passes.CNC automatic feeding machines are a type of CNC machine that automates the process of feeding raw materials into the machine for processing. This not only saves time and labor costs but also ensures consistent and accurate feeding of materials, leading to improved product quality and reduced waste.

flex feeders for sale

If it's more the holes that bother you, out could get some thin pieces of wood trim and hot glue that over it. Peal and stick vinyl or wall paper. You could cut it into strips to cover the track and use the remainder to cover the shelves if you like. Would also make it easy to change the look of it down the road.How to hide ugly shelf brackets? We have several shelves on those ugly old metal wall brackets. I would love a creative solution to hide them of cover them. You could just buy .

cnc automatic feeding machine suppliers|automatic lathe feeders